Lotus root washing machine

A lotus root washing machine and lotus root machine technology, applied in the fields of application, food processing, food science, etc., can solve the problems of low production efficiency, high labor intensity, poor decontamination effect, etc., and achieve fast cleaning, high cleaning efficiency and low labor intensity low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

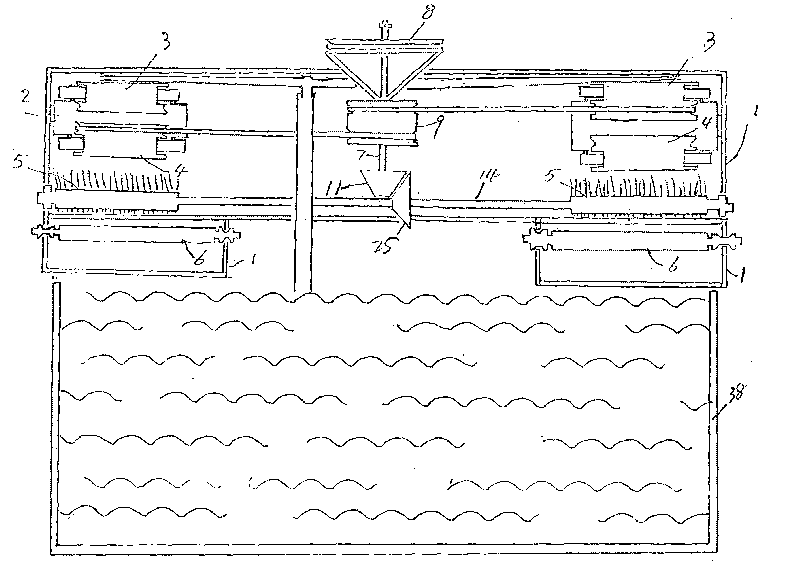

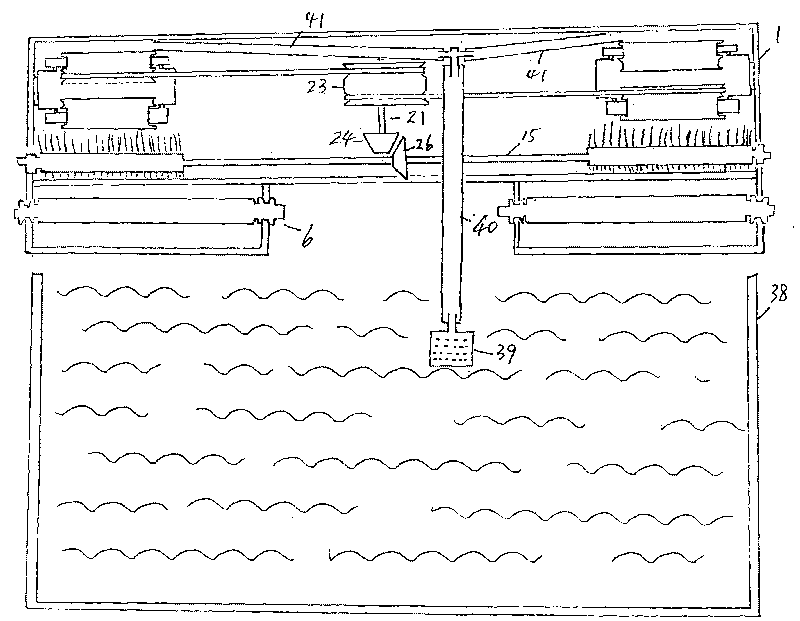

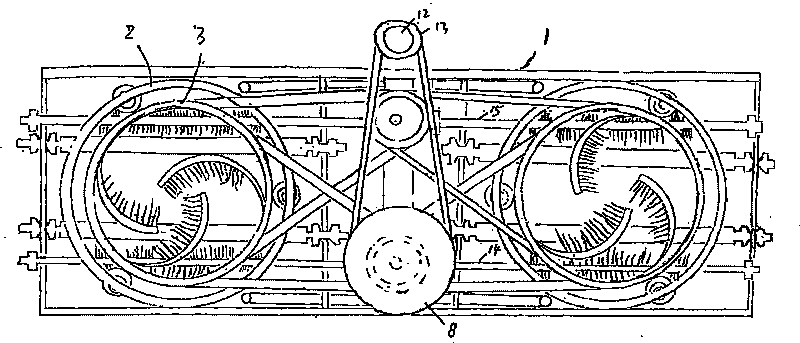

[0020] Frame 1 is positioned on water tank 38. Vertical shafts 7, 21 and horizontal shafts 18 are supported on the crossbeam 35 of the frame 1, and horizontal shafts 14, 15 are supported on the crossbeam 36. Belt pulley 8,9, bevel gear 10,11 are arranged on vertical shaft 7. Belt pulley 23 and bevel gear 22,24 are arranged on vertical shaft 21. Belt pulley 8 is connected with belt pulley 13 on the output shaft of motor 12 by transmission belt, belt pulley 9 is connected by belt pulley on the upper inner bucket 9 on the right end of the frame and the belt pulley on the lower inner bucket 4 on the left end of the frame, and belt pulley 23 is connected with the machine by belt. The belt pulley on the lower inner bucket 4 on the right-hand side of the frame is connected with the belt pulley on the inner bucket 3 on the left end of the frame. Upper and lower inner buckets are supported on the bearings on the vertical circle 2 on the frame. The bevel gear 10 is transmission-conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com