Cleaning device and cleaning method for optical coating clamp

A technology of optical coating and cleaning device, which is applied in the direction of using liquid cleaning methods, chemical instruments and methods, cleaning methods and utensils, etc., which can solve the problems of low efficiency, slow cleaning speed, long time, etc., and achieve improved cleaning efficiency, cleaning High efficiency and short cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

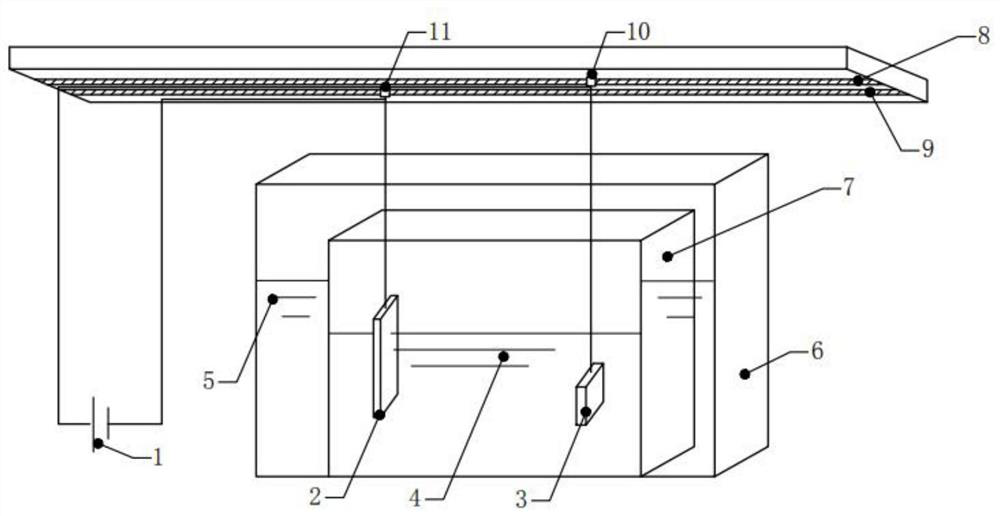

[0039] A cleaning device for an optical coating jig, such as figure 1As shown, it includes a DC power supply 1, an ultrasonic oscillator 6 and a reaction vessel 7; the model of the DC power supply 1 is AN5330-150, one end of the positive lead is connected to the positive pole of the DC power supply 1, and the other end of the positive lead is connected to the optical coating fixture 3 One end of the negative lead is connected to the negative pole of the DC power supply 1, and the other end of the negative lead is connected to the platinum sheet 2; the optical coating jig 3 as the anode and the platinum sheet 2 as the cathode are placed in the electrolyte 4 In the reaction vessel 7, in this embodiment, the reaction vessel 7 is a polytetrafluoroethylene container, the platinum sheet 2 is partially immersed in the electrolyte 4, and the optical coating jig 3 is completely immersed in the electrolyte 4; In the ultrasonic oscillator 6 of the ionized water 5. Among them, NaOH, NaCl...

Embodiment 2

[0054] According to the method for optical coating fixture cleaning described in embodiment 1, its difference is:

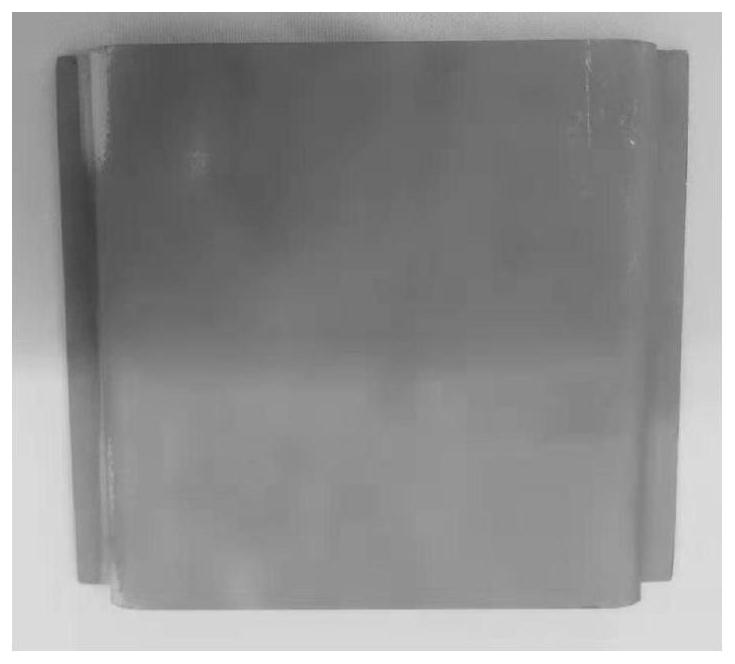

[0055] The optical coating jig 3 used in this embodiment has the same state as the optical coating jig 3 used in Embodiment 1.

[0056] NaOH, NaCl and H in electrolyte 4 2 O mass ratio 2:5:4.

[0057] In step (1), the optical coating jig 3 is put into the electrolyte solution 4 for immersion treatment, and the immersion time is 30 minutes.

[0058] In step (2), the DC power supply 1 is started first, and the DC power supply 1 adopts a constant voltage mode. The working time of the DC power supply 1 is 20 minutes, and the DC voltage is 30V.

[0059] In step (3), keep the DC power supply 1 to continue working, and at the same time turn on the ultrasonic oscillator 6, and start the ultrasonic oscillator 6 to work for 20 minutes.

[0060] In step (4), the optical coating jig 3 is taken out, and the optical coating jig 3 is rinsed with deionized water for 20 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com