Full-automatic ultrasonic shoe washing machine

An ultrasonic and shoe washing machine technology, which is applied in the field of automatic ultrasonic shoe washing machines, can solve the problems of time-consuming and labor-consuming, friction and collision, easy damage to the shoe washing machine and shoes, and achieve the effect of improving the cleaning quality and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific examples are given below to further describe the technical solution of the present invention in a clear, complete and detailed manner. This embodiment is the best embodiment on the premise of the technical solution of the present invention, but the protection scope of the present invention is not limited to the following embodiments.

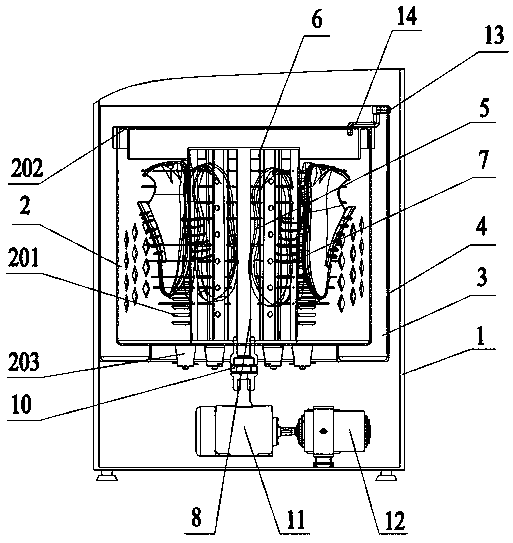

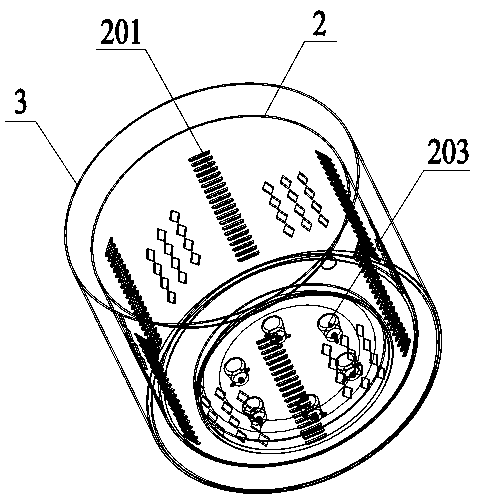

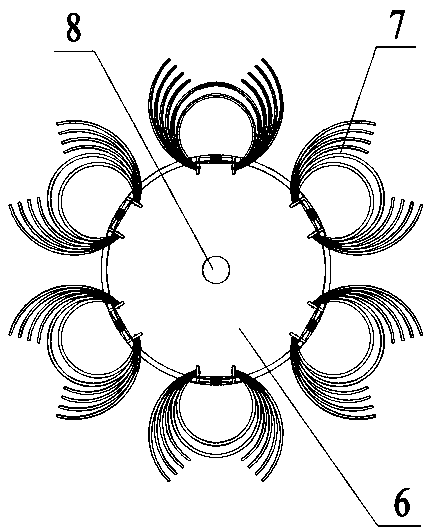

[0025] A fully automatic ultrasonic shoe washing machine, comprising a casing 1 and a control system, the casing 1 is fixedly arranged with a dehydration bucket 2 and a water bucket 3 sequentially from the inside to the outside. Different, fix the dehydration bucket 2 and the water bucket 3, and rotate through the clamping device 5 to achieve the purpose of uniform cleaning and dehydration;

[0026] The outer wall of the water bucket 3 is provided with a heating device 4, the heating device 4 is electrically connected to the control system, and includes a plurality of superimposed heating metal plates. During the process of ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com