Lateral pressure-type equipment special for cleaning high-rise glass curtain wall

A glass curtain wall and special equipment technology, applied in the field of cleaning, can solve the problems of short continuous working time, high power consumption, high equipment cost, etc., achieve the effect of cleaning without dead ends and reducing the load of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

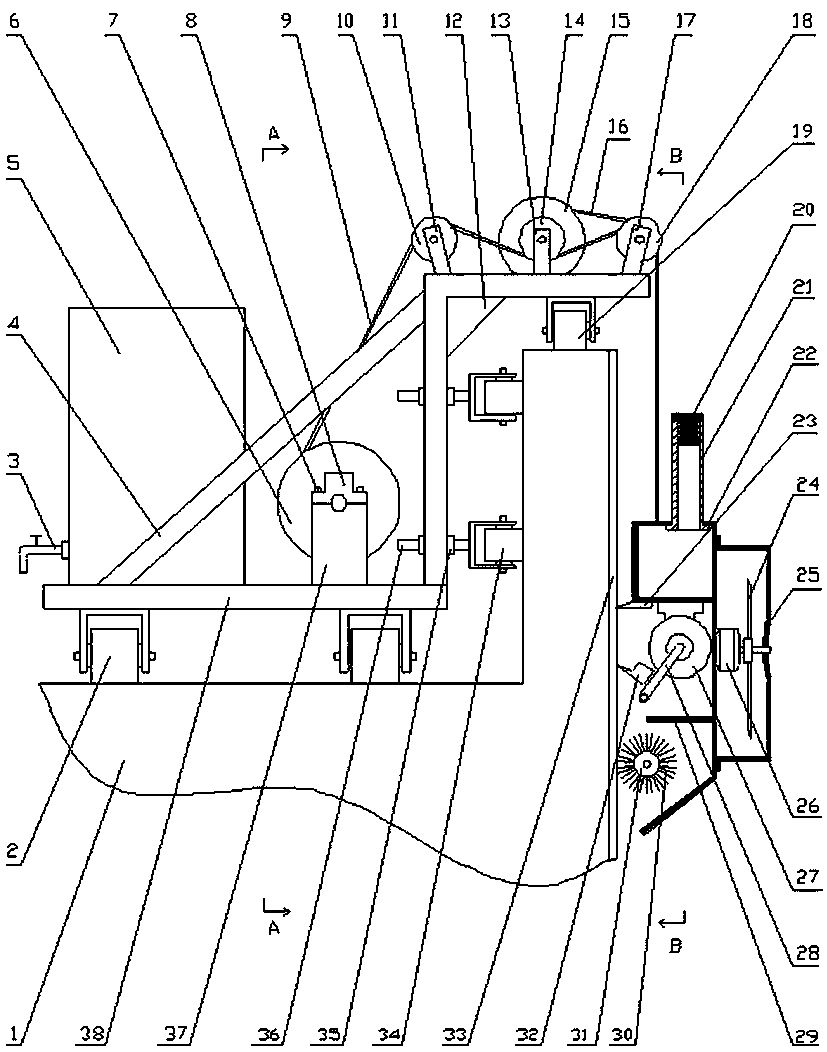

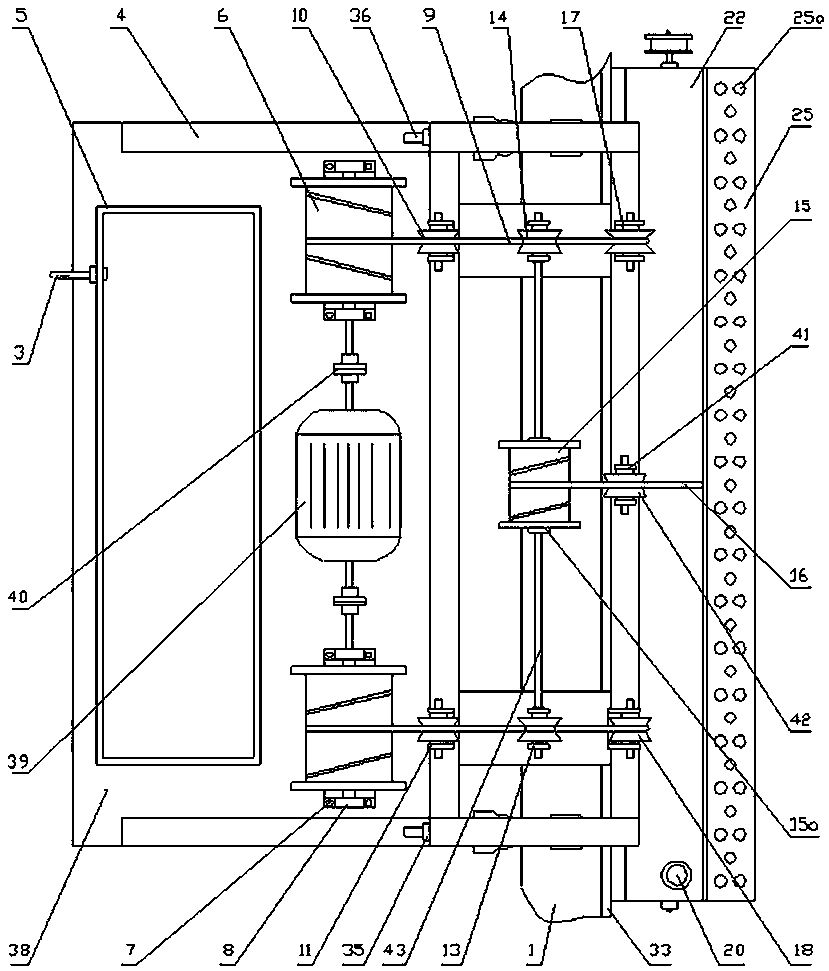

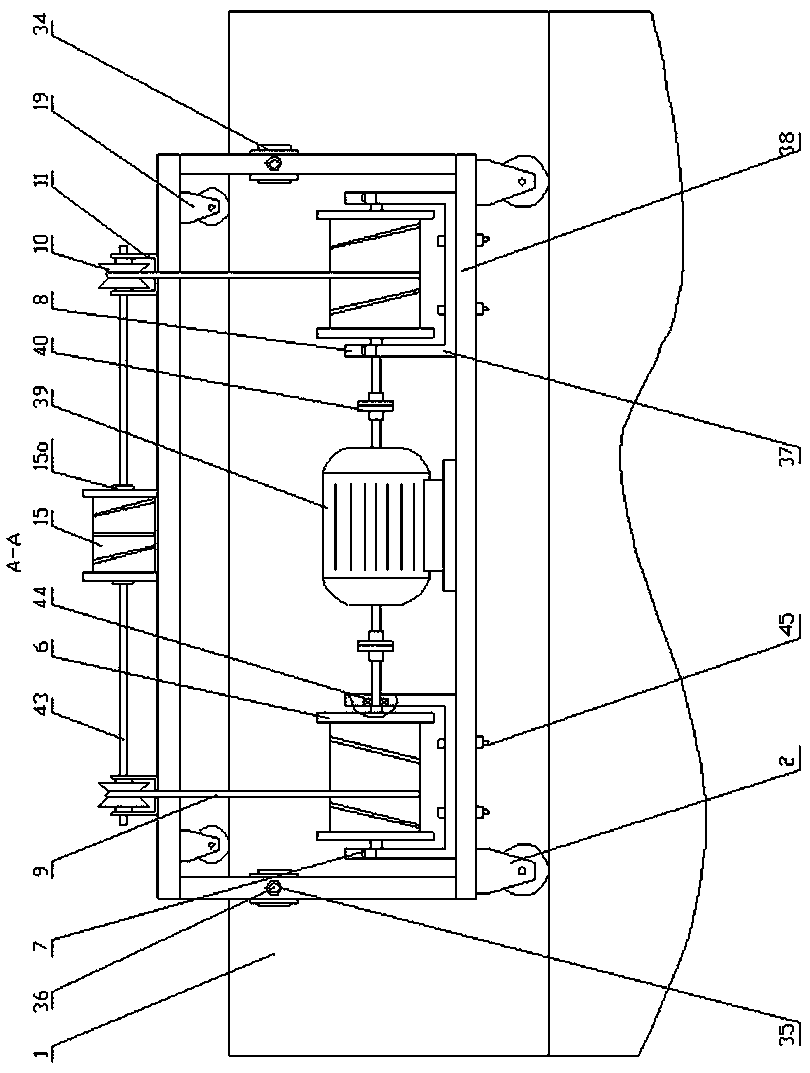

[0010] Such as Figure 1~Figure 5 As shown, the present invention is a special equipment for cleaning high-rise glass curtain walls with lateral pressure. The frame 38 is in an inverted Z shape. Diagonal tie rods 4 are welded between the left and middle parts of the frame 38. Between the middle and right parts of the frame 38 Welded with reinforcing ribs 12, four casters 2 are fixedly installed under the left part of the frame 38, and the casters 2 are placed horizontally on the roof 1. Among the four casters 2, two are universal wheels and the other two are fixed wheels. , the right side of the middle part of the frame 38 is fixedly installed with four guide wheels 34 through the limit nut 35 and the screw rod 36, the guide wheels 34 are close to the inside of the wall of the roof 1, and the bottom of the right part of the frame 38 is fixedly installed with four auxiliary wheels. Wheel 19, auxiliary wheel 19 are horizontally placed on the top of the wall of building roof 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com