A kind of blank forging method

A billet forging and rotary forging technology, applied in the field of forging technology, can solve problems such as complicated processes, and achieve the effects of reducing forging costs, improving plasticity and reducing fire times.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Step: 1: Heating the forging, formulating a suitable heating process according to the thermal conductivity of the material and the change of the specific heat capacity, to ensure that the core of the forging is forged, so as to improve the plasticity of the forging and reduce the deformation resistance of the forging;

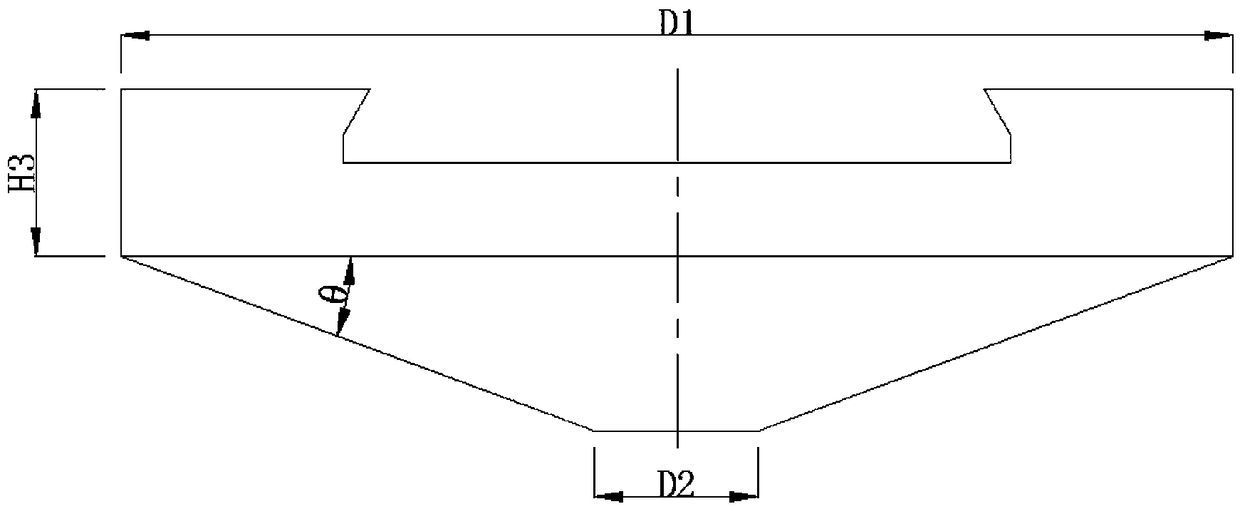

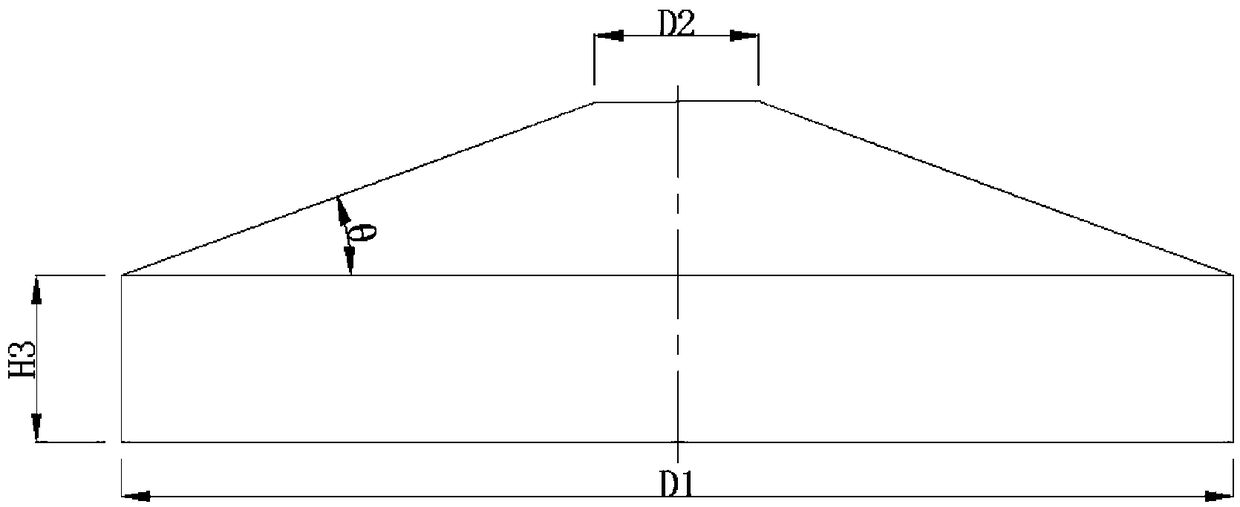

[0036] Step 2: Open the blank forging, and specifically divide the upsetting and elongation process to improve the overall uniformity of the forging and eliminate the difficult-to-deform area;

[0037] Step 3: return to the furnace to heat the forging: when the temperature of the forging is lower than 800°C, stop forging and return to the furnace for heating;

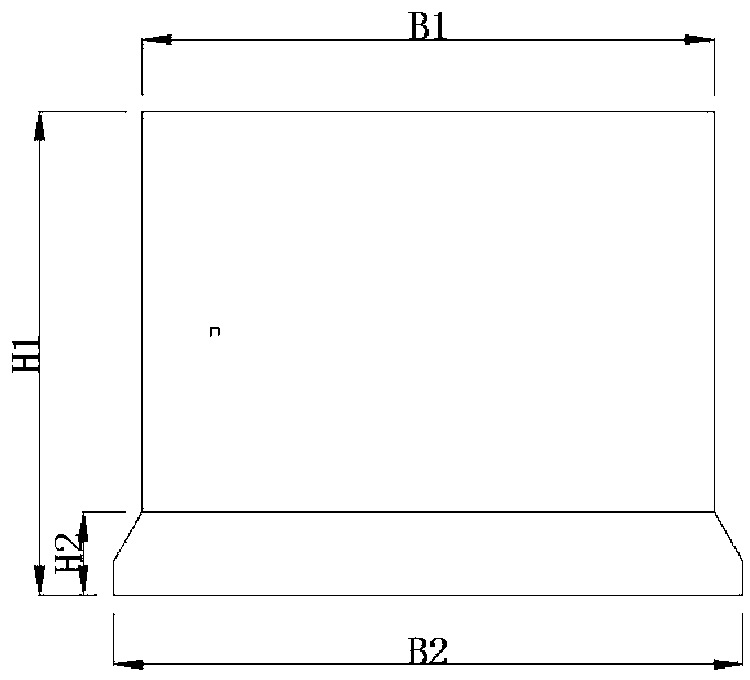

[0038] Step 4: Forming, forging the steel ingot to the target forging shape;

[0039] Step 5: Carry out heat treatment to the forging after forging.

[0040] Preferably, the process of heating the forging described in step 1 is: the temperature of the furnace is 600°C-650°C, and the temperature i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com