Trough type photo-thermal power generation system

A solar-thermal power generation and trough-type technology, applied in solar thermal power generation, solar heating systems, solar heat storage, etc., can solve the problems of heavy workload for operators, increased difficulty of manual cleaning, and reduced light concentration efficiency of solar thermal power generation systems, etc. problem, to reduce the probability of occurrence and shorten the time for downtime maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

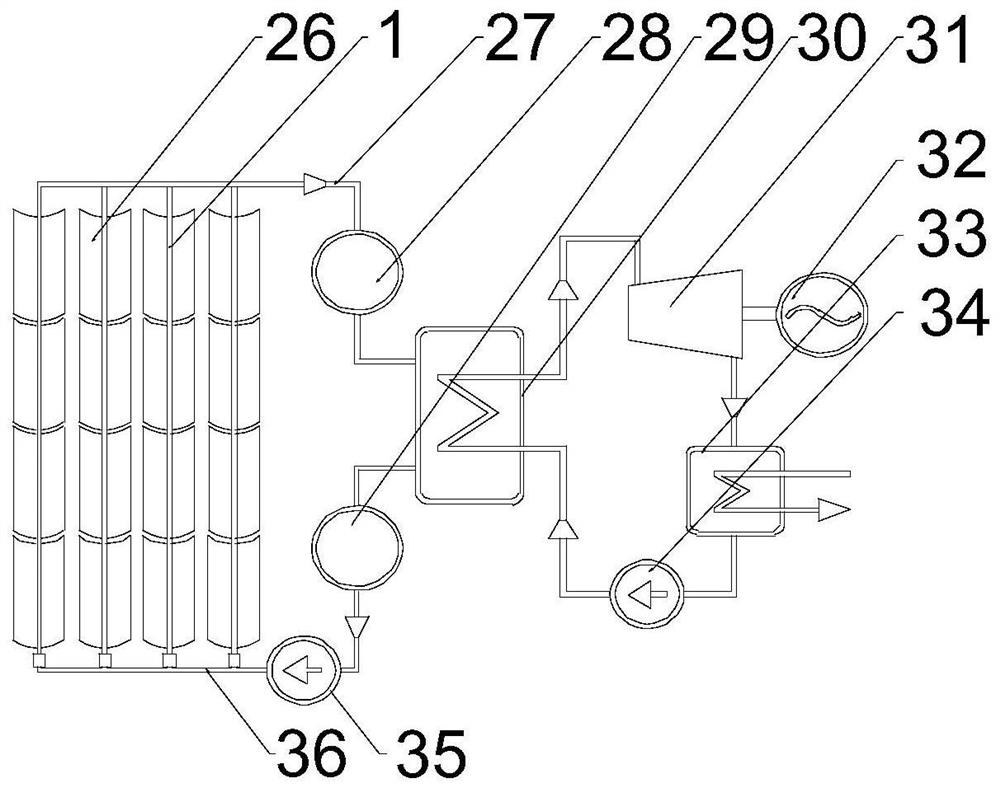

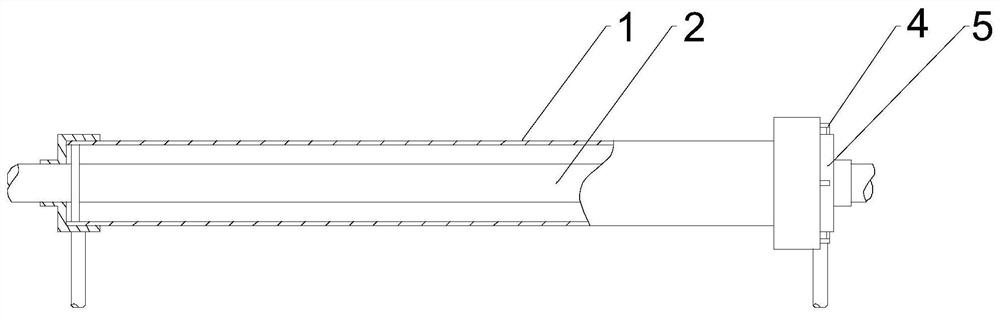

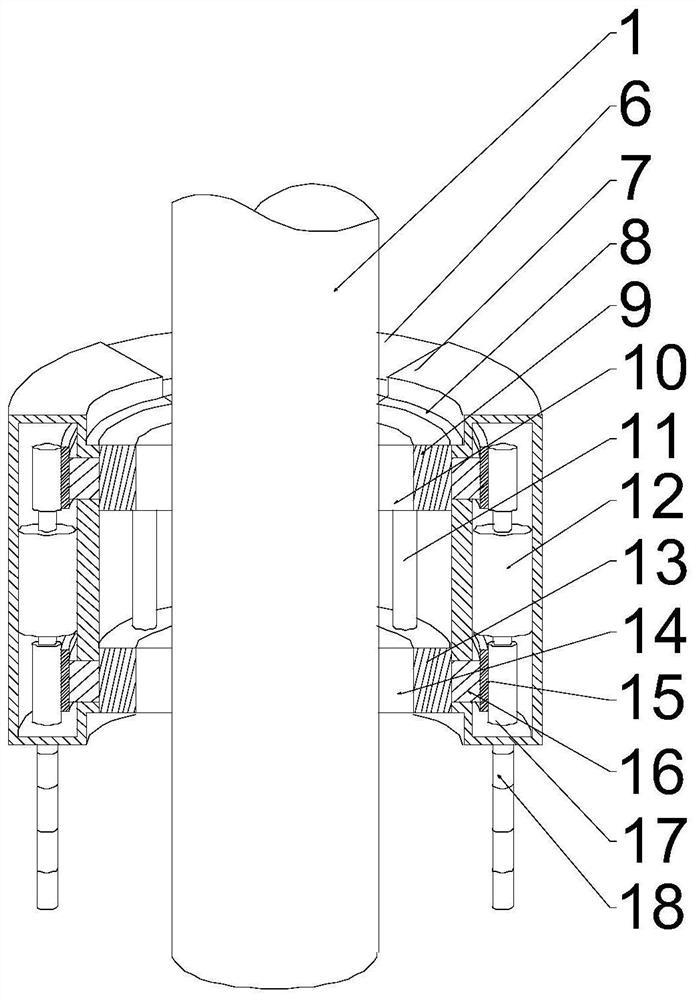

[0029] Such as Figure 1~6 As shown, the present embodiment includes multiple rows of heat collecting plates 26, each row of said heat collecting plates 26 is provided with a support rod, the support rod is provided with an annular joint 5, and the protective tube 1 runs through a plurality of joints 5, each A molten salt pipe 2 is provided inside a protection pipe 1, and one end of a plurality of molten salt pipes 2 communicates with a high-temperature pipeline 27, and the other end of a plurality of molten salt pipes 2 communicates with a low-temperature pipeline 37, which is characterized in that: Each of the protection tubes 1 is provided with a cleaning mechanism, and the high-temperature pipeline 27 is sequentially connected with the high-temperature storage tank 28, the liquid inlet of the heat exchanger 30, the liquid inlet of the steam turbine 31, and the generator 32. The pipeline 37 is sequentially connected with the liquid outlet of the cryogenic storage tank 29, t...

Embodiment 2

[0034] Such as Figure 2-6 As shown, in this embodiment, on the basis of Embodiment 1, baffle plates are provided on the two inner walls at both ends of the arc-shaped cavity, and baffle plates are provided on the two side walls of each follower plate 20. The pins 22, in the initial state, the follower plate 20 moves through the gap between the two baffles and then extends to the middle of the arc-shaped cavity, and the two pins 22 are respectively in contact with the inner side walls of the baffles. When the two movable plates 6 fully entered the arc cavity, the adjustment gear 19 and the rack 21 kept in contact all the time, so as to realize the spacing of the follower plate 20 and the movable plate 6, and when the movable plate 6 moved from the arc When moving out of the cavity, in order to prevent the movement of the other movable plate 6 from being hindered due to the excessive displacement of one of the movable plates 6, baffle plates are respectively provided on the two...

Embodiment 3

[0037] Such as Figure 2-6 As shown, in this embodiment, on the basis of Embodiment 1, arc-shaped grooves 8 are formed on both ends of the fixing plate 7 , and the arc-shaped grooves 8 match the joints 5 . When the housing is located at the beginning of the protective tube 1 or moved to the terminal of the protective tube 1, the electrical components in the housing are in an idle state, and the arc-shaped grooves 8 at both ends of the fixing plate 7 can be overlapped on the joint 5, and the arc-shaped concave There is a certain static friction force between the groove 8 and the outer wall of the joint 5. Compared with the case completely sleeved on the protection tube 1, the contact area between the whole device and the protection tube 1 and the joint 5 is larger, and the force is more balanced, avoiding the device Rotation occurs on the protection tube 1, and the speed of the driving motor and the bidirectional motor 12 is preset, and the components in a stable state can ensu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com