Automatic cleaning water storage pool

An automatic cleaning and storage tank technology, which is applied in the configuration of water supply tanks, water supply devices, cleaning hollow objects, etc., can solve the problems of increased cleaning work of the storage tank, humid and hot storage tanks, and inability to clean the storage tank, etc. To achieve the effect of reducing resistance, reducing weight and facilitating discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

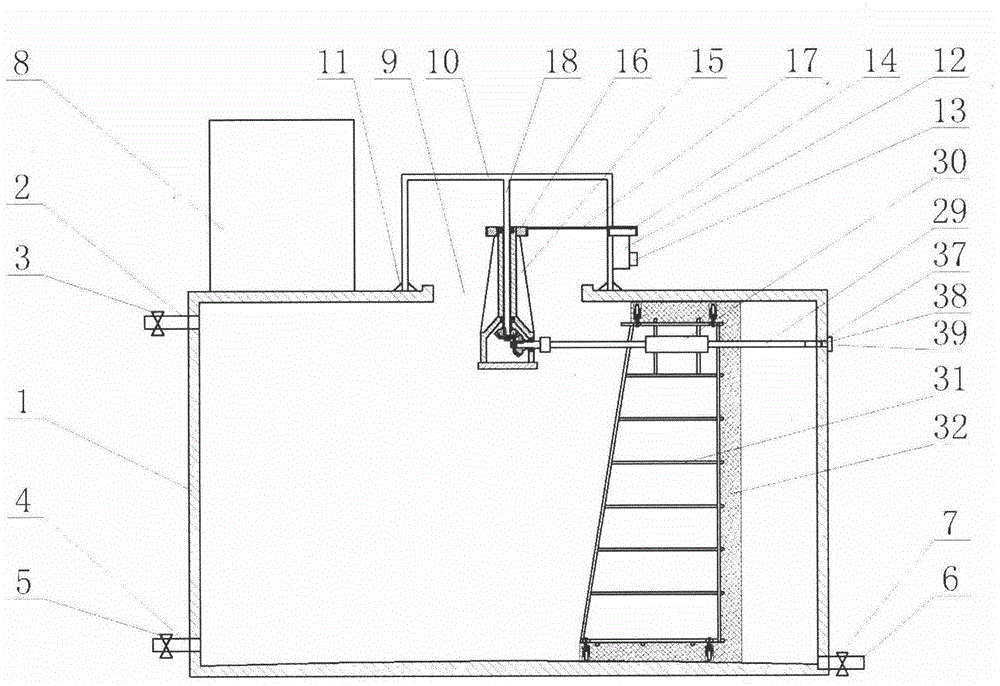

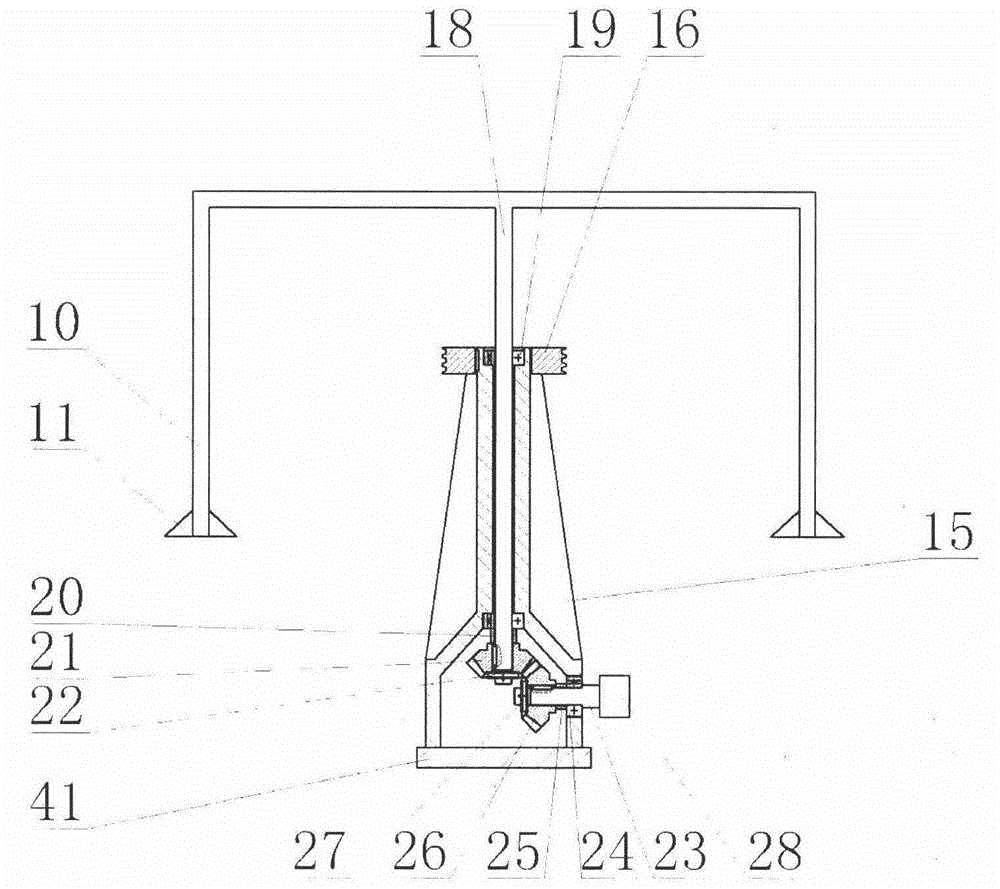

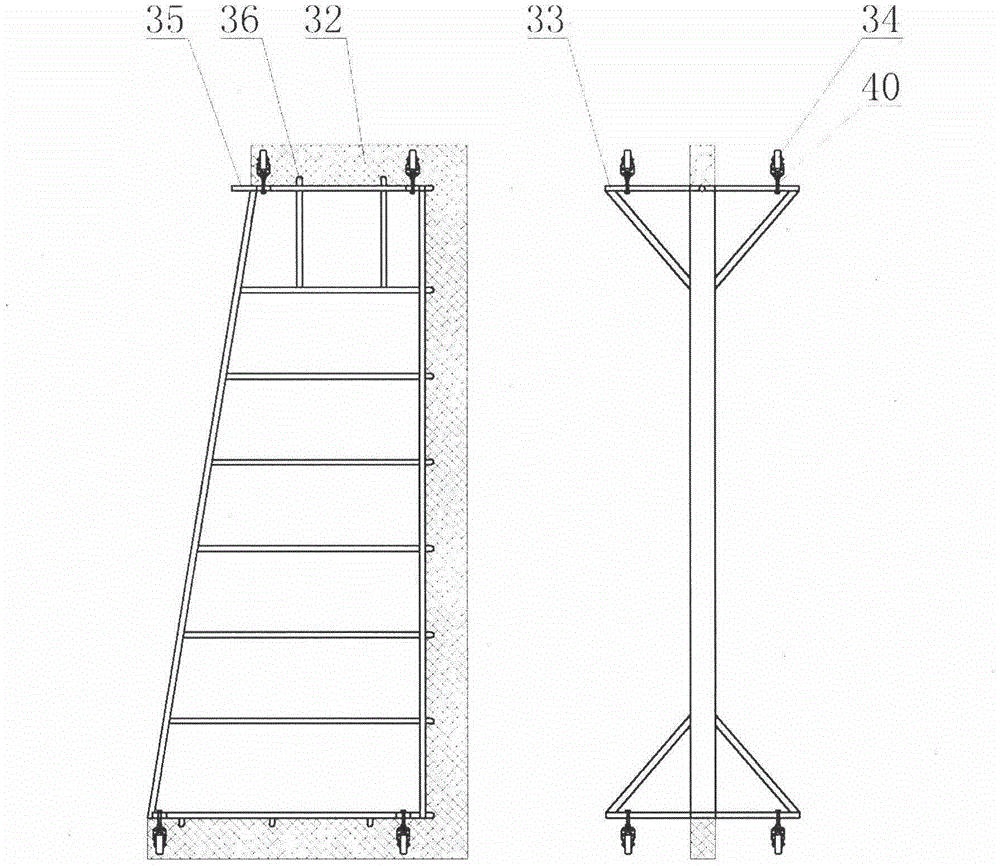

[0033] Embodiment 1, the water storage tank is a cylindrical airtight structure, which can effectively prevent rainwater, dust and other sundries from falling into the water storage tank. The upper part of the water storage tank is provided with a water inlet, and the water inlet is provided with a water inlet valve. The lower part of the water storage tank is provided with a water outlet, the water outlet is provided with a water outlet valve, the bottom of the water storage tank is provided with a sewage outlet, the sewage outlet is provided with a sewage discharge valve, and a small spare pool, which can provide water source for cleaning the reservoir, and ensure non-stop water during cleaning; the top of the reservoir is provided with a manhole, the top of the manhole is provided with a bracket, and the bottom of the bracket is provided with a foot support, and the bracket passes through The bolts in the foundation support are fixed on the top of the reservoir; a motor is s...

Embodiment 2

[0034] Embodiment 2, the storage tank is a cylindrical airtight structure, which can effectively prevent rainwater, dust and other sundries from falling into the storage tank; the bottom surface of the storage tank is a spherical surface with a high middle and low surroundings, which can better collect dirt. To facilitate the discharge of sewage; the upper part of the reservoir is provided with a water inlet, the water inlet is provided with a water inlet valve, the lower part of the reservoir is provided with a water outlet, and the water outlet is provided with a water outlet valve, and the water storage The bottom of the pool is provided with a sewage outlet, the sewage outlet is provided with a sewage valve, and a small spare pool is provided above the reservoir, which can provide water for cleaning the reservoir and ensure non-stop water during cleaning; the water reservoir The top of the pool is provided with a manhole, the top of the manhole is provided with a bracket, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com