Stirring device capable of monitoring concrete slump degree and automatically cleaning

A technology of automatic cleaning and stirring device, applied in cement stirring device, control device, clay preparation device, etc., can solve the problems of uneven stirring, worn stirring blade and inner side, hidden danger of quality and safety, etc. Unnecessary economic losses and benefits to the people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

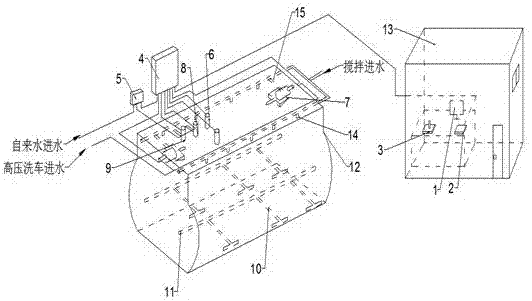

[0025] See figure 1 In the embodiment of the present invention, the mixing device for monitoring concrete slump and automatic cleaning, the main installation positions and structural components are:

[0026] Operation room 13: monitor 1, video recorder 2, joystick operation keyboard 3;

[0027] Outside of mixer 12: power distribution cabinet 4, high-pressure water spray system 5, pipeline fan and butterfly valve 6;

[0028] Inside the mixer 12: an all-round high-pressure automatic cleaning machine 7, a monitoring head 8, and an LED light 9.

[0029] The high-pressure water spray system 5, the pipeline fan and the butterfly valve 6, the omni-directional high-pressure automatic cleaning machine 7, the monitoring head 8, and the LED light 9 are electrically connected to the power distribution cabinet 4; the monitoring head 8, the LED light 9 are also connected to the high-pressure water spray system 5 connection. The omnidirectional high-pressure automatic cleaning machine 7, the monit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com