Die with temperature control function

A function and mold technology, applied in the field of molds with temperature control function, can solve the problems of secondary deformation, low reliability of use, burrs at the punching of the plate, etc., to avoid corrosion damage and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The invention realizes the temperature control function of the mold through a temperature control system of spraying, air drying and water collection.

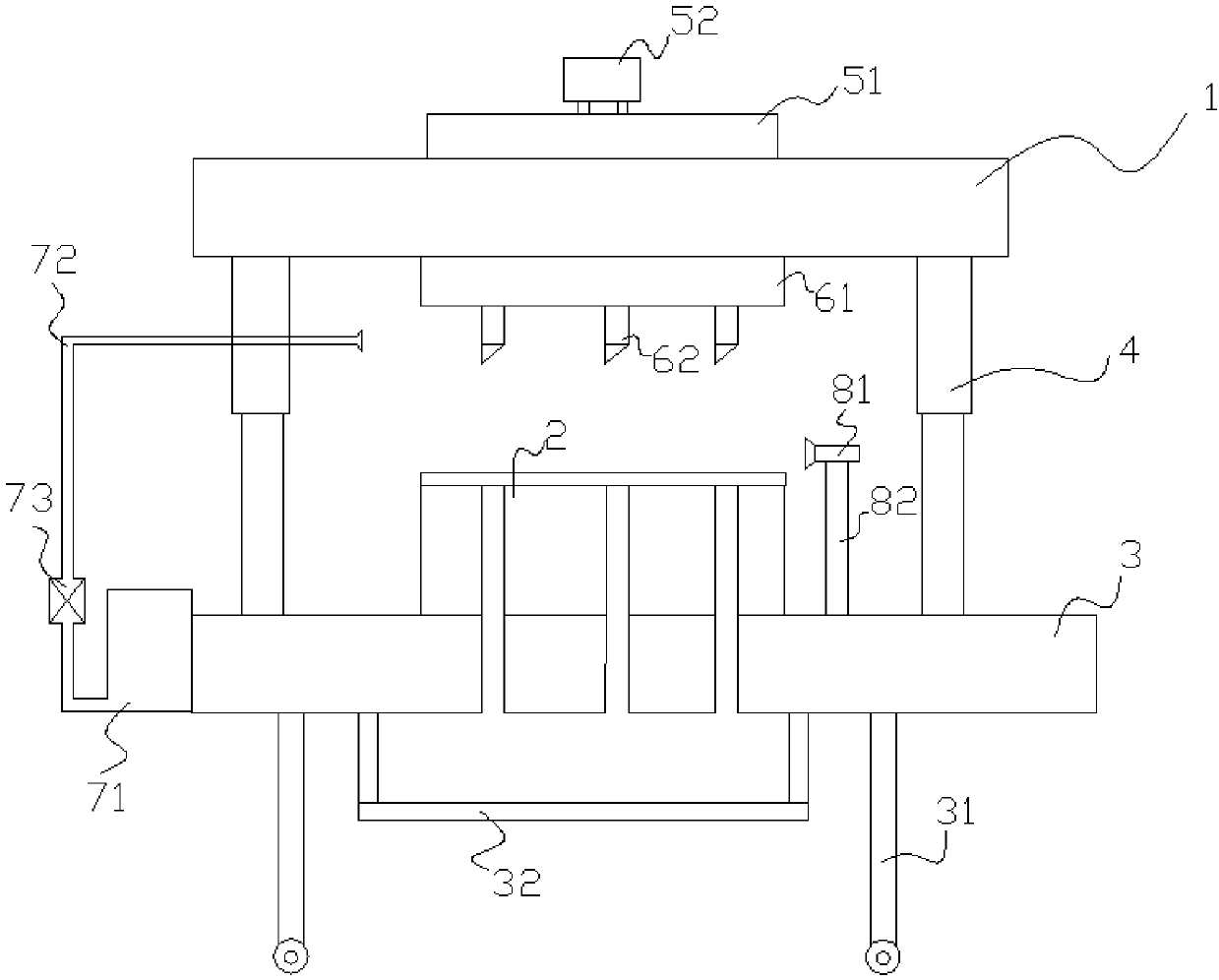

[0020] see figure 1 , a mold with a temperature control function, comprising an upper mold 1, a lower mold 2, a base 3 and a guide rod 4; connect. A lower mold 2 is installed on the top of the base 3 . The top surface of the lower mold 2 is parallel to the bottom surface of the upper mold 1 .

[0021] The top of the upper die 1 is provided with an upper push plate 51 and a motor 52; connected.

[0022] A cutter head 61 is provided at the bottom of the upper mold 1 . The cutter head 61 is bolted to the bottom of the upper mold 1 , and a cutter 62 is provided at the bottom. Preferably, the knives 62 can be more than two groups.

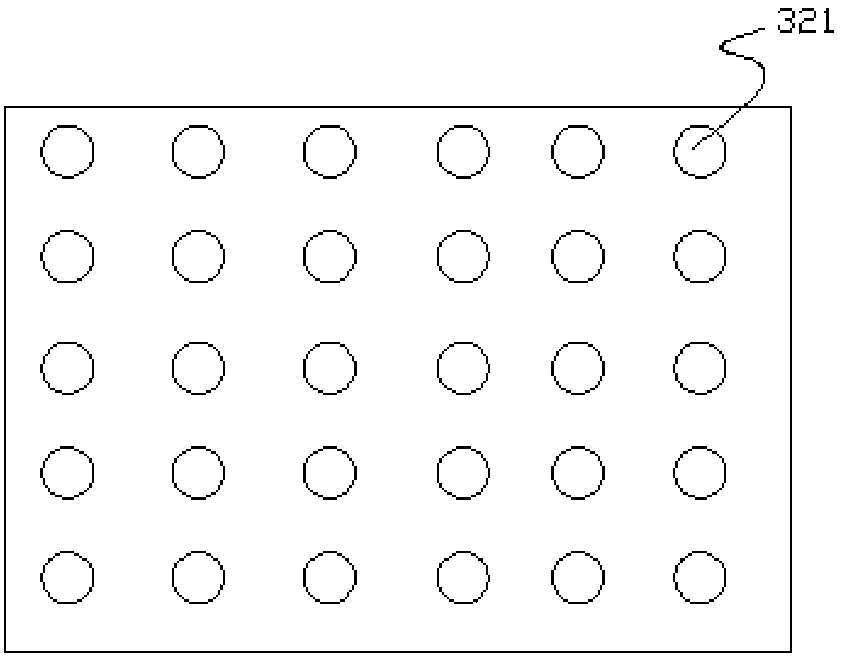

[0023] The lower mold 2 is provided with unloading channels, and each set of unloading channels corresponds to the position and diameter of the cutter 62 . The base 3 is provided with dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com