Automatic blanking device of full-automatic steel bar straightening cutting and hooking all-in-one machine

A blanking device, fully automatic technology, applied in the field of hoop bending machine, can solve the problems of difficult production, inability to produce, and no automatic blanking system of hoop bending machine, etc., to achieve the effect of solving difficult or impossible production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

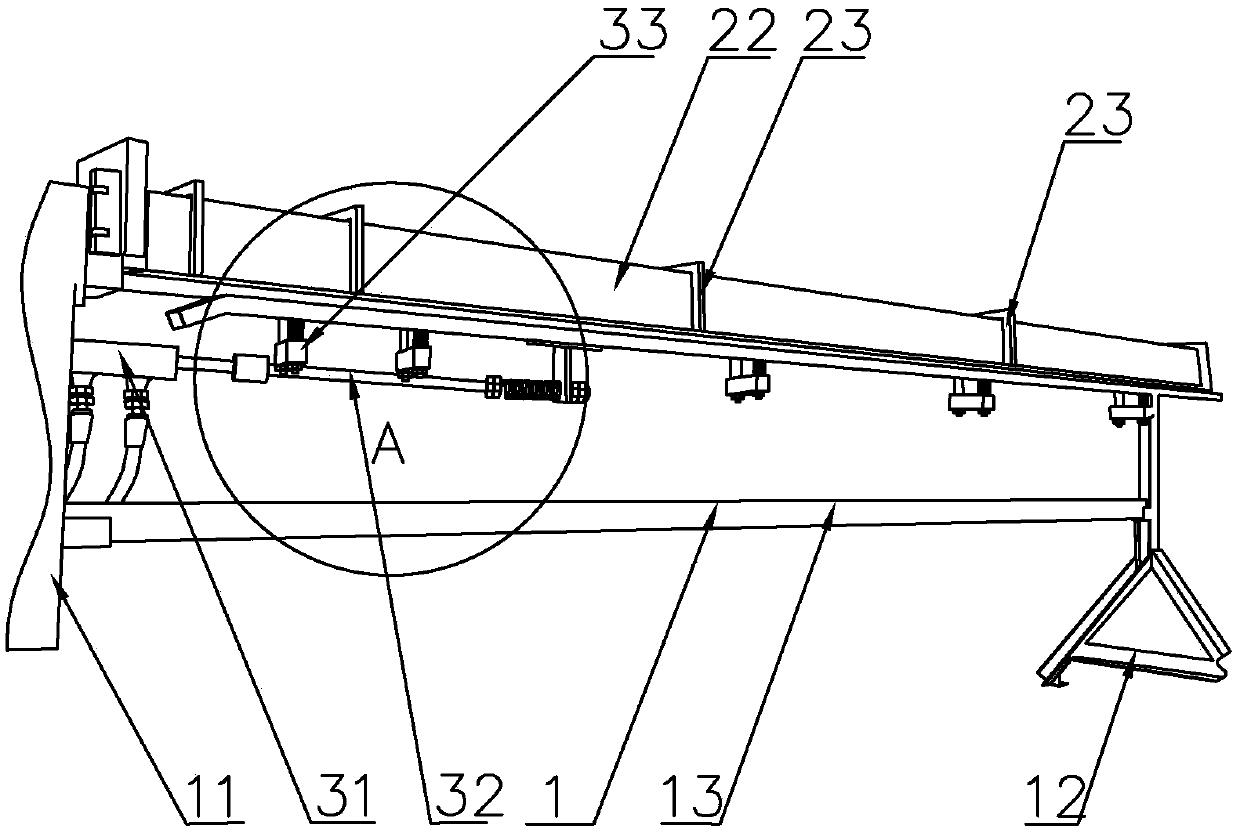

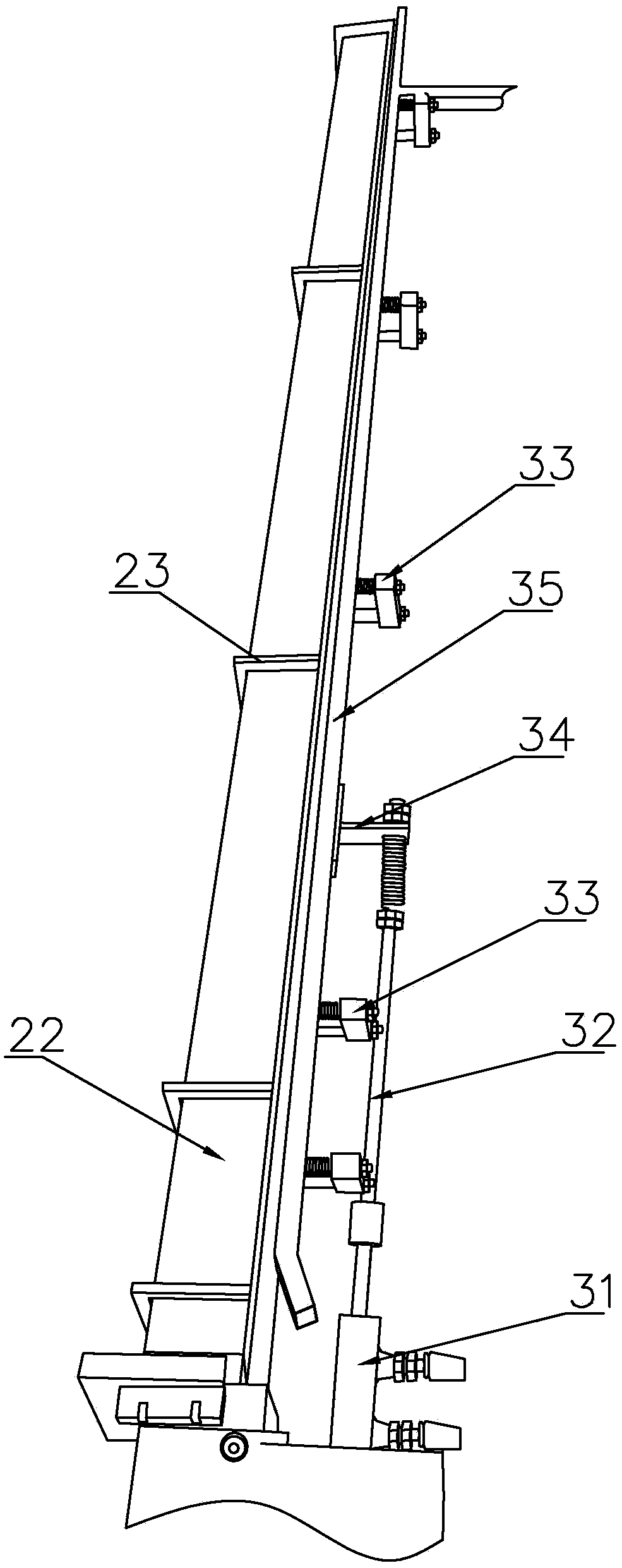

[0033] Such as Figure 1-4 As shown, the automatic blanking device of the fully automatic steel bar straightening and cutting hook integrated machine includes a support frame 1, a material guide mechanism 2 and a blanking mechanism 3, and the support frame 1 includes a left frame 11, a right frame 12 and a connecting plate 13. The left frame 11 and the right frame 12 are respectively fixedly installed on the left and right ends of the connecting plate 13;

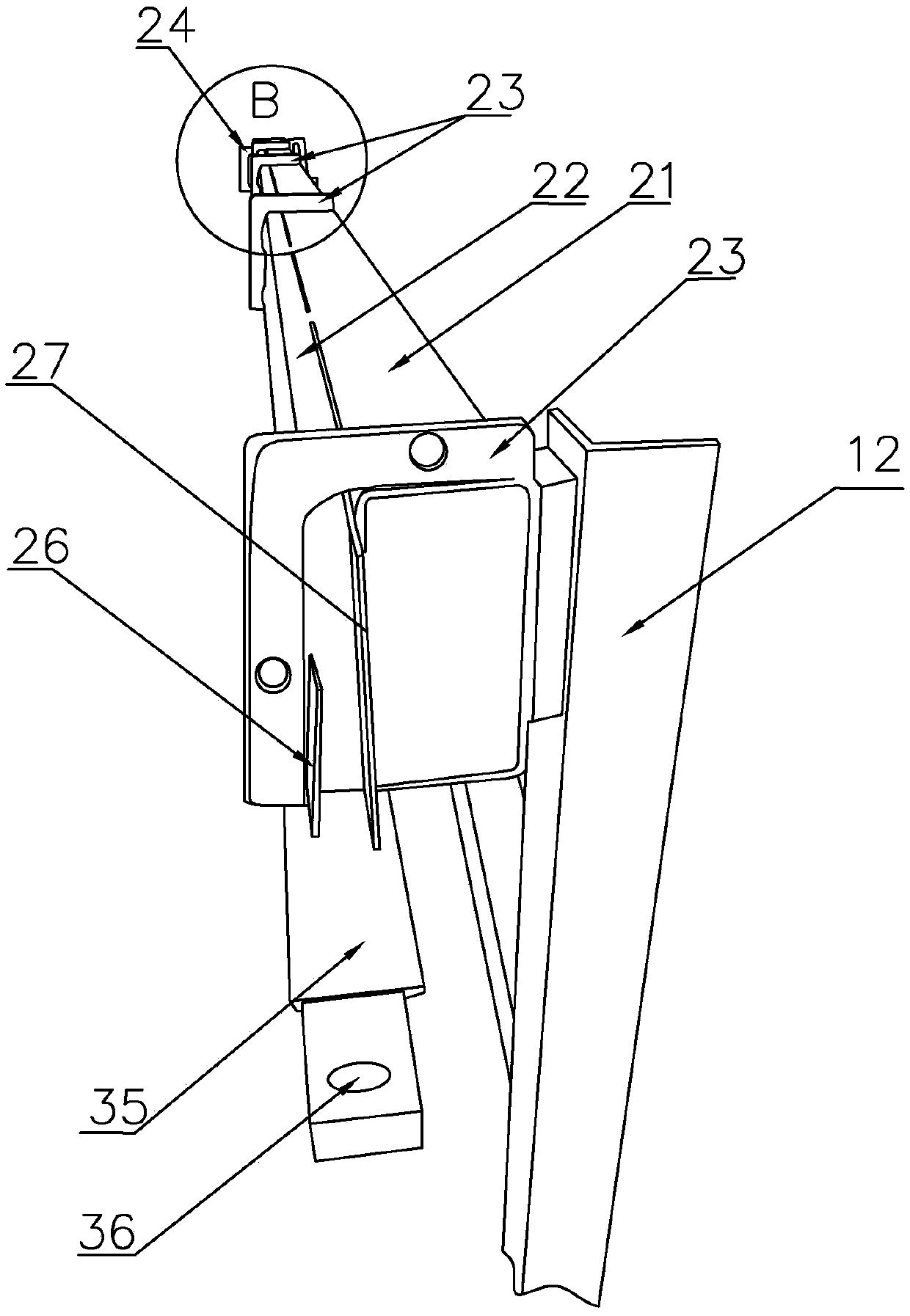

[0034] The material guide mechanism 2 includes a material guide plate one 21, a material guide plate two 22, a connector one 23, a connection ear one 24 and a connection ear two 25, and the material guide plate one 21 is fixedly installed with the left frame 11 and the right frame. The upper part of the rear end of the frame 12, the second material guide plate 22 is fixedly installed on the rear of the first material guide plate 21 through several connectors one 23, and the connecting ear one 24 is fixedly installed on the ...

Embodiment 2

[0039] Such as figure 2 As shown, the automatic blanking device of the fully automatic steel bar straightening and cutting hook integrated machine is different from the embodiment 1 in that the right end of the blanking plate 35 is provided with a mounting hole 36 penetrating up and down, and the guide The right end of the plate one 21 is fixedly installed with a clamping plate one 26, and the right end of the guide plate two 22 is fixedly installed with a clamping plate two 27. When a longer steel bar needs to be processed, a fully automatic steel bar straightening and cutting The length of the automatic blanking device of the hook integrated machine is not enough. We can adopt the method of connecting the automatic blanking devices of two fully automatic steel bar straightening and cutting hook integrated machines to achieve the purpose of processing longer steel bars for smooth production.

[0040] working principle:

[0041] The cutting height of the fully automatic stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com