A device for quickly replacing the damaged tooth seat of the cutting head with high precision on site

A high-precision, cutting head technology, used in auxiliary devices, welding/cutting auxiliary equipment, auxiliary welding equipment, etc., can solve the problem of high time cost and maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

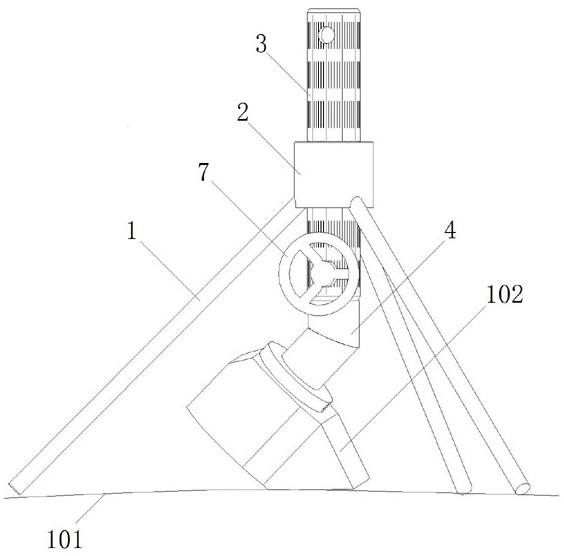

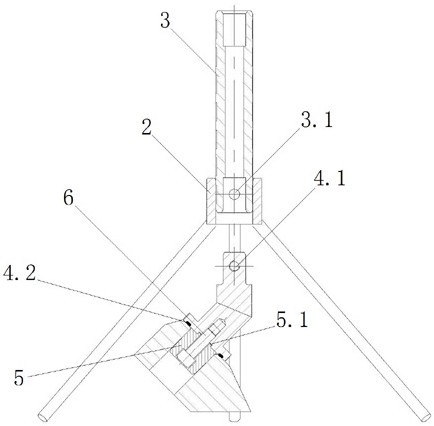

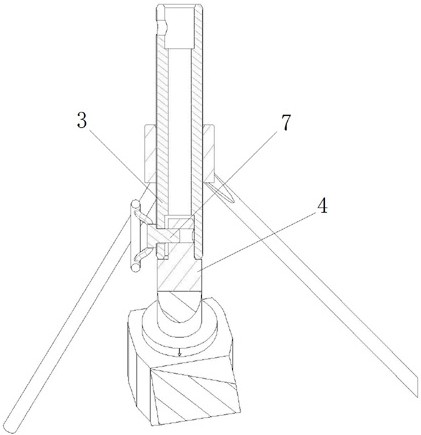

[0017] This embodiment provides an on-site high-precision and quick replacement device for damaged tooth seats of cutting heads, including metal brackets 1, cantilever brackets 2, corner connecting rods 3, tooth seat positioning shafts 4, tooth seat shaping columns 5, mounting screws 6 and Lock the handwheel 7; the top end of the metal bracket 1 is welded on the cantilever bracket 2, and the bottom end is welded on the surface 101 of the cutting head to enclose the worn tooth seat; Hole, etched 0° line on the upper end surface; the corner connecting rod 3 passes through the installation hole, the rod body is etched along the circumferential direction, and the side wall near the bottom is provided with a first through hole 3.1; the tooth seat is positioned The shaft 4 is a bent rod-shaped structure, and the bending angle is the supplementary angle of the characteristic angle of the tooth holder 102. For example, if the characteristic angle of the tooth holder 102 is 45°, the ben...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com