A kind of pvc cable pipe fast cutting equipment

A technology of cutting equipment and cable ducts, which is applied in metal processing and other directions, can solve the problems of inability to integrally cut cable ducts and difficult to collect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

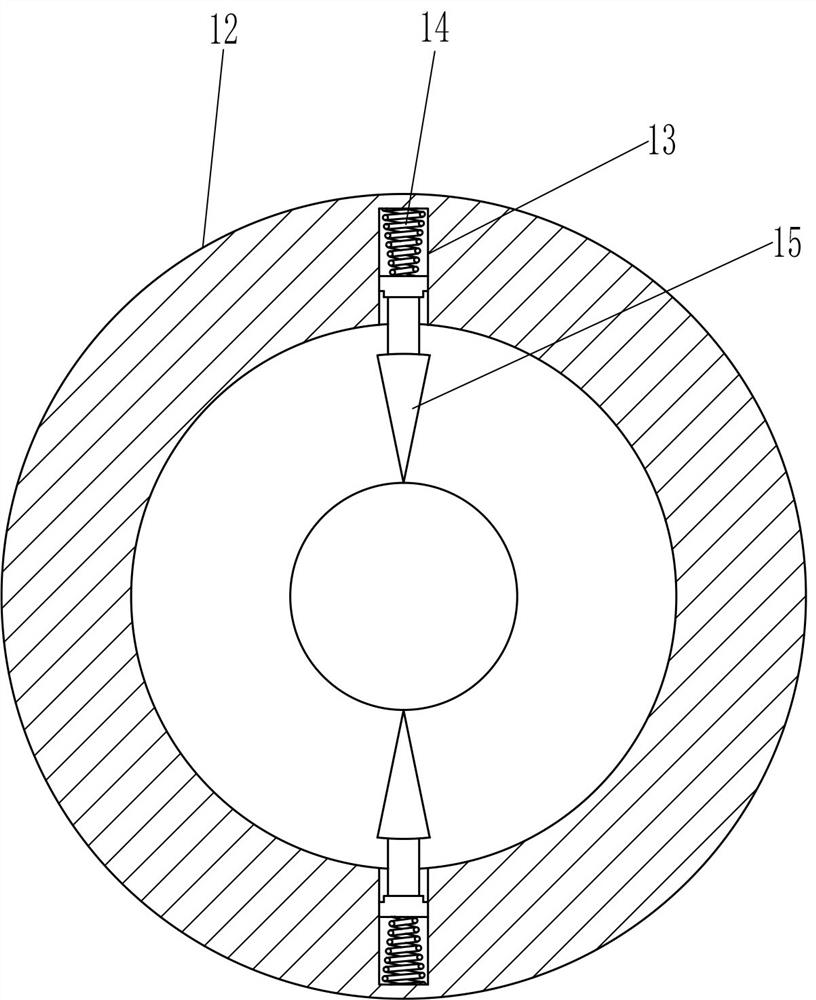

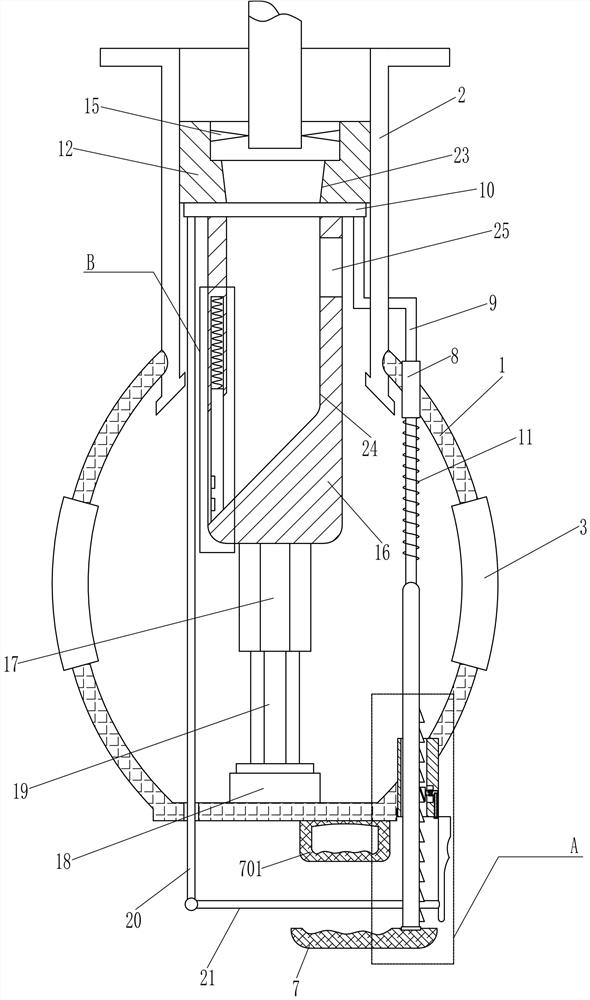

[0020] A kind of PVC cable pipe fast shearing equipment, such as Figure 1-3 As shown, it includes a mounting frame 1, a mounting frame 2, a rubber sleeve 3, a guide sleeve 4, a spine 5, a clamping device 6, a handle 7, a frame 701, a guide sleeve 8, a push rod 9, a support ring 10, a Two compression springs 11, concave circular block 12, conical spring 14, cutter 15, connecting column 16, inner hexagonal sleeve 17, motor 18, hexagonal sleeve rod 19, T-shaped bar 20, connecting rod 21 and baffle plate 22 , the top of the installation frame 1 is provided with the installation frame 2, the middle part of the installation frame 1 is provided with a rubber sleeve 3, the lower part of the right side of the installation frame 1 is provided with a guide sleeve 4, and the inside of the guide sleeve 4 is slidably connected with a spine 5, and the right part of the guide sleeve 4 A clamping device 6 is provided, a handle 7 is provided at the bottom of the spine 5, a handle frame 701 is ...

Embodiment 2

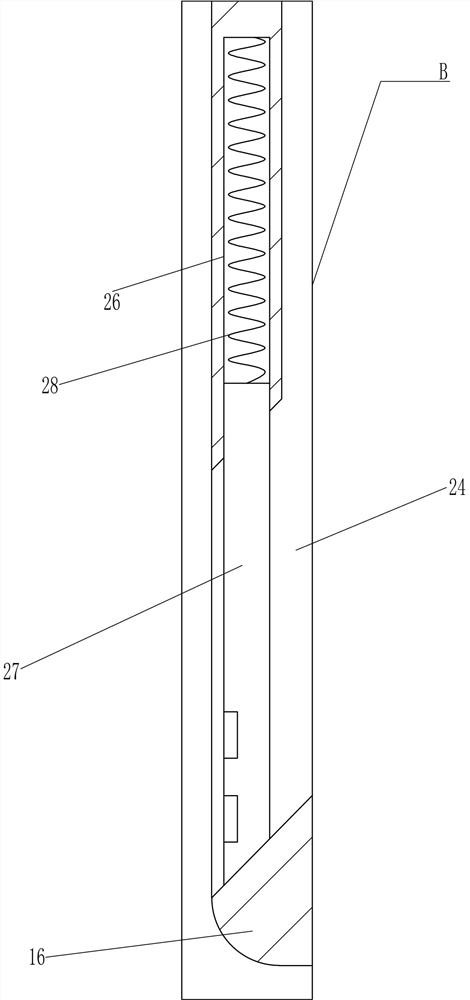

[0024] On the basis of Example 1, such as figure 1 and Figure 4 As shown, it also includes a transparent plate 25, an arc-shaped plate 27 and a third compression spring 28. A cavity 24 is opened in the connecting column 16, and the cavity 24 is connected with the inclined groove 23. The upper right side of the connecting column 16 is provided with a transparent Plate 25, connecting column 16 left side lower part has arc-shaped groove 26, and arc-shaped plate 27 is slidably connected in arc-shaped groove 26, and the third compression spring 28 is connected between the arc-shaped plate 27 top and arc-shaped groove 26.

[0025]When the redundant part of the cable tube is cut off, the cut cable tube directly falls into the cavity 24 connected to the inclined groove 23, and a certain amount of cable tubes can be collected through the cavity 24, which saves manual labor. The operation steps of manually cleaning the cable tubes are convenient for workers to continuously cut multipl...

Embodiment 3

[0027] On the basis of Example 2, such as image 3 As shown, a bolt 30 is also included, the lower right side of the sliding rod 62 and the right side of the guide sleeve 4 are provided with threaded holes 29, and the threaded holes 29 on both sides are connected with the same bolt 30 by threaded connection.

[0028] When the normal operation of the equipment is required, the bolt 30 is unscrewed from the sliding rod 62. When it is necessary to prevent the ratchet 5 from continuing to move upward due to the worker's accidental touch, the bolt 30 is screwed into the sliding rod 62 again. With the effect of effectively fixing some parts of the equipment, the effect of insurance is achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com