Equipment for sticking labels on panels of customized furniture

A label and plate technology, which is applied in the field of equipment for labeling custom furniture plates, can solve the problems of low processing efficiency, expensive equipment, and low reliability, and achieve the effects of small equipment, low cost, and reduced labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

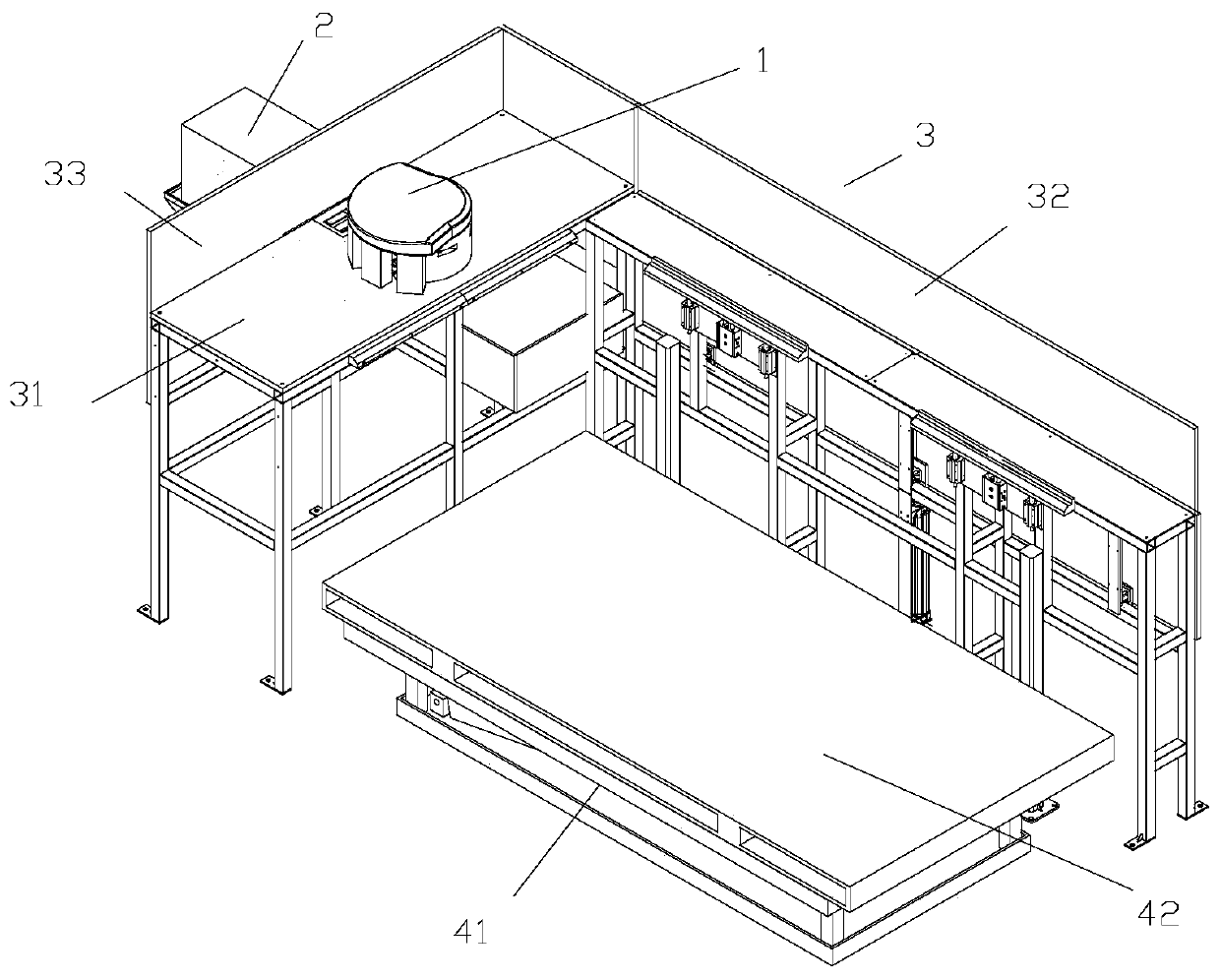

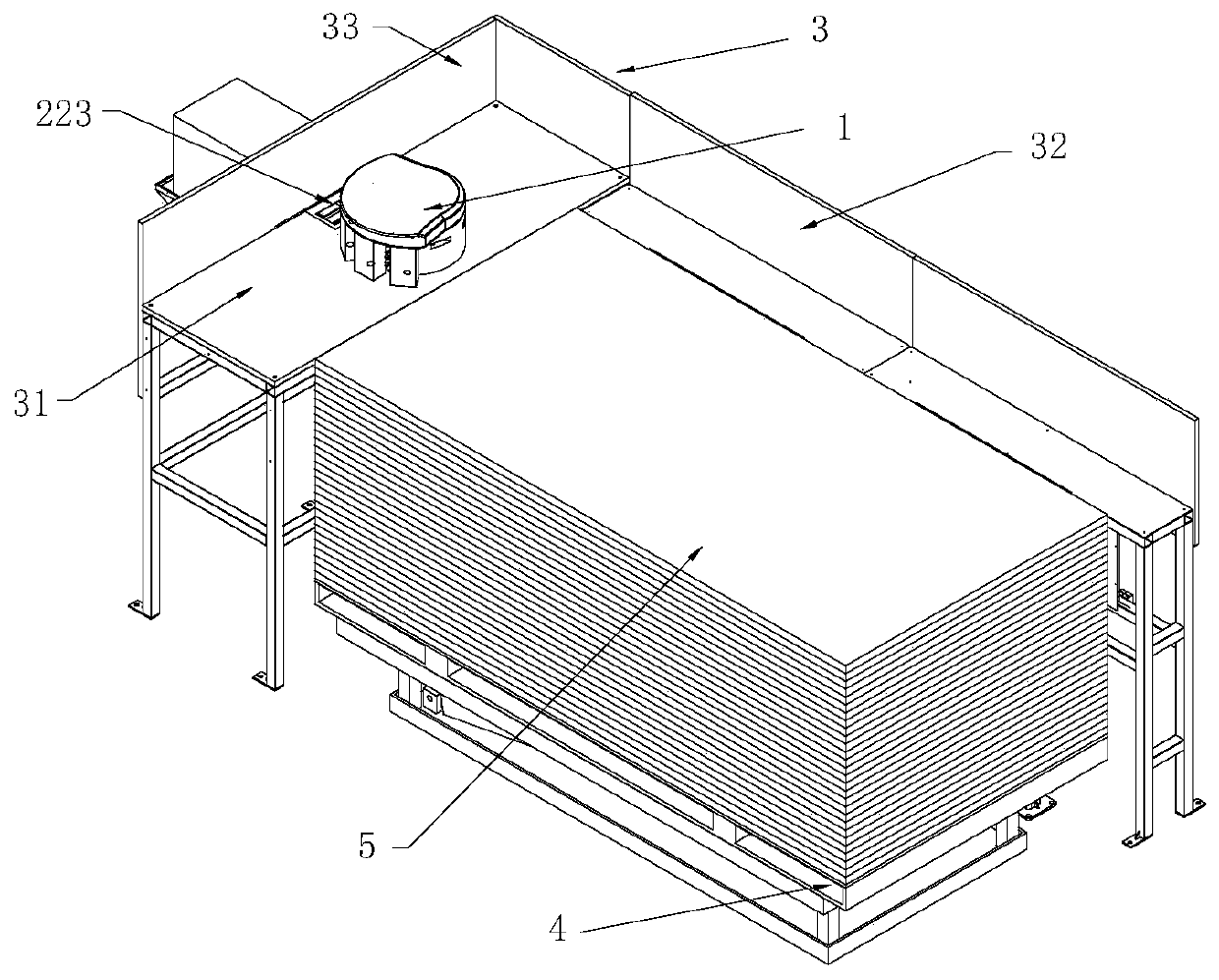

[0053] This embodiment is a kind of equipment for customizing the label of furniture plate, its structure is as follows Figure 1 to Figure 13 shown, including:

[0054] Rack 3;

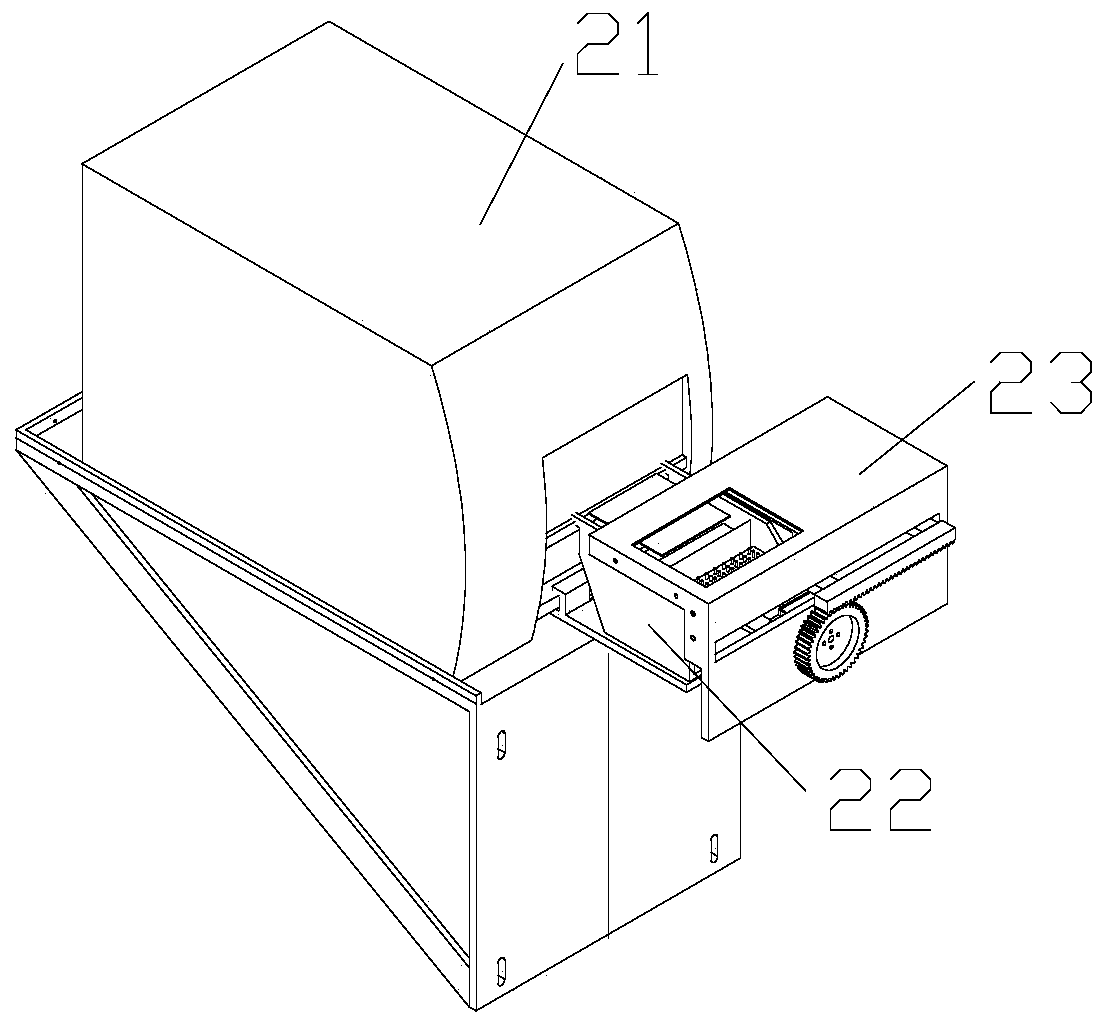

[0055] A label printing and peeling device 2 for printing labels and placing the labels on the label receiving platform 223 after peeling off the backing paper;

[0056] Plate lifting device 4 for storing plates and adjusting the height of plates;

[0057] And a label sticking trolley 1 for taking out the label on the label receiving platform and walking to the plate with the label for label sticking;

[0058] The frame 3 is provided with a label-taking platform 31 that forms the movement plane of the label sticking trolley 1; the label-connecting platform 223 is located on the label-taking platform 31; the plate lifting device 4 is located on one side of the label-taking platform 31; the label sticking trolley 1 is movable Set on the standard-taking platform 31.

[0059] The working principle of...

Embodiment 2

[0088]This embodiment is used to customize the equipment for pasting labels on furniture panels. The difference from Embodiment 1 is that in this embodiment, the positioning sensing module of the label pasting trolley also includes a gyroscope for detecting yaw angles. In order to improve the operating efficiency, a gyroscope is added; when the label sticking car is stationary, the X-direction ultrasonic positioning component and the Y-direction ultrasonic positioning component are used to obtain and adjust the angle of the label sticking car; when the label sticking car is moving , only obtain the yaw angle through the gyroscope to obtain the angle of the label sticking car and adjust it; it can avoid the slow response caused by the large amount of data calculation during the movement, and can improve the operating efficiency. This ensures the coexistence of high efficiency and precision in the movement of the label sticking trolley. The rest of the structure of this embodime...

Embodiment 3

[0090] This embodiment is used to customize the equipment for sticking labels on furniture panels. The difference from Embodiment 1 is that in this embodiment, the label receiving platform is set close to the label taking platform; the label sticking car walks on the edge of the label taking platform, and the label sticks The label taking device of the sticking trolley is relative to the position of the label receiving platform, so that the label sticking trolley can take the label away. The rest of the structure of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com