Bottom supporting device for rotary drilling rig special for railway and application method thereof

A technology of rotary drilling rig and bottom support, which is applied to supporting devices, drilling equipment and methods, earth-moving drilling, etc., can solve the problems of inconvenient transportation of the bottom support device of a rotary drilling rig for railways, restrictions on construction sites, and limitations in use. , to achieve the effect of facilitating transportation and use, increasing stability and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

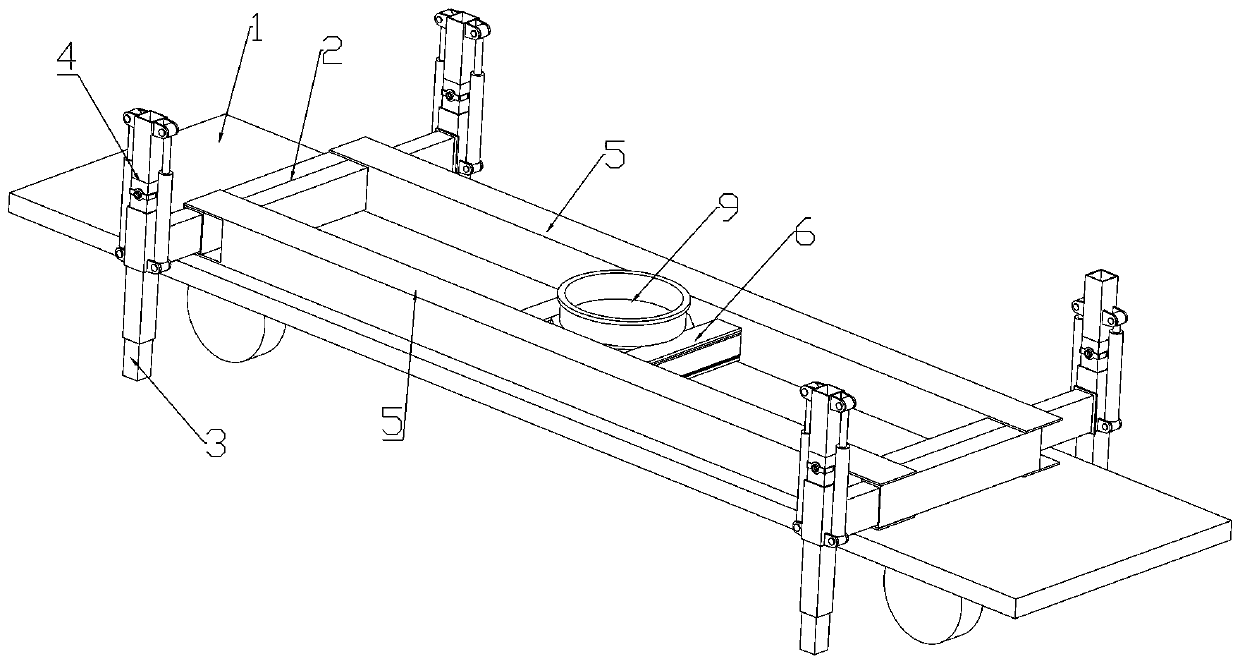

[0033] Example 1 A Bottom Support Device for Railway Special Rotary Drilling Rig

[0034] In this embodiment, the expansion and contraction of the telescopic mechanism on the support frame is controlled by the driving mechanism, so that the rotary drilling rig can be stably supported by extending the telescopic arm 2 and telescopic legs during railway line construction, and can be shortened during transportation. , Telescoping legs for easy transport.

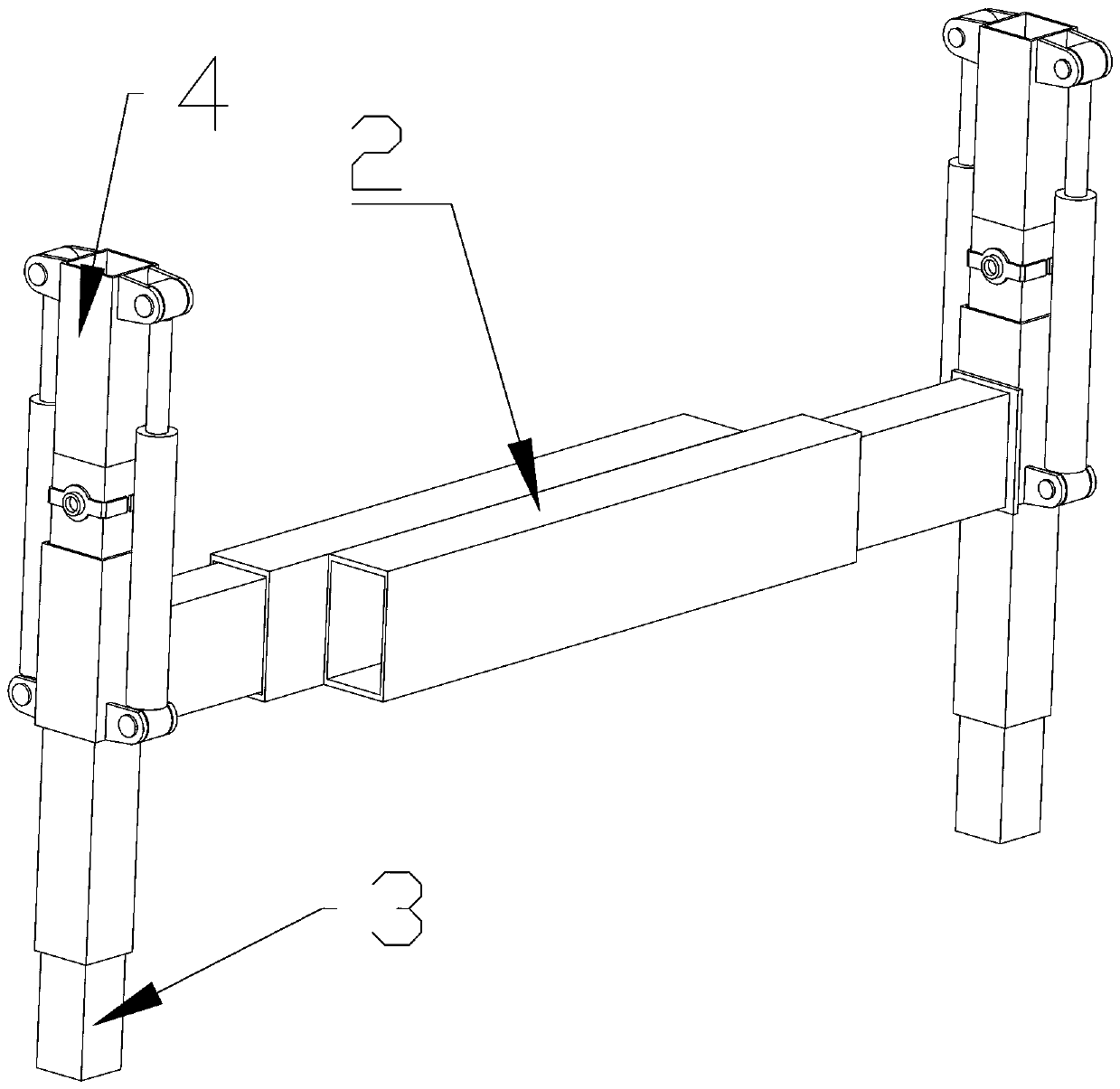

[0035] Such as Figure 1 to Figure 2 As shown, this embodiment includes a support frame, a telescoping mechanism and a driving mechanism.

[0036] 1. Support frame

[0037] The support frame is used to support the rotary drilling rig. The support frame is a frame-shaped structure arranged horizontally, and the top surface of the support frame is placed on a horizontal plane. In order to facilitate the movement of the support frame, a moving mechanism is provided below the support frame to move the support frame on the railw...

Embodiment 2

[0048] Embodiment 2 A method of using the bottom support device of a special railway rotary drilling rig

[0049] This embodiment utilizes the bottom supporting device of the railway-specific rotary drilling rig in Embodiment 1, and is used in conjunction with the rotary drilling rig for construction on railway lines. The method of using the bottom supporting device of the railway-specific rotary drilling rig includes the following steps:

[0050] S1. Move the support frame to the working position through the flat car.

[0051] S2. Drive the telescopic arm 2 to extend horizontally to the working position through the hydraulic cylinder, that is, the telescopic arm 2 drives the telescopic legs at both ends of the telescopic arm 2 to move outward relative to the support frame.

[0052] S3. Drive the first telescopic leg 4 to extend downward in a direction perpendicular to the horizontal plane through the hydraulic cylinder, that is, the first telescopic leg 4 drives the second tele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com