A Tensile Microstress Detection Method for Performance Degradation of Fiber Reinforced Composite Materials

A composite material and fiber-reinforced technology, which is applied in the analysis of materials, strength characteristics, and the use of stable tension/pressure to test the strength of materials, etc., can solve the problem of varying severity of defect damage, defect characteristic size dispersion, response analysis and life prediction The role of limited and other problems, to achieve the effect of rapid prediction and evaluation

Active Publication Date: 2022-05-31

HANGZHOU JIANTU TECH

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the variety of internal defects in the composite material structure, the characteristic size of the defects is dispersed, and the severity of the defect damage is different, tracking the specific position, shape and size of a single defect has a very limited effect on the overall behavioral response analysis and life prediction of the composite material structure.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0048] The tensile load includes a uniform tensile load and a concentrated tensile load.

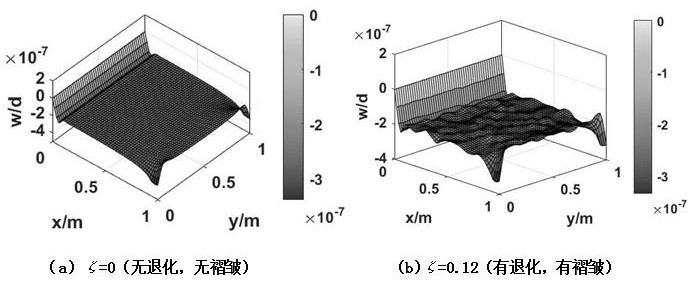

[0049] The folds and corrugations created above are an elastic response and therefore require only a small tensile load on the structure

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

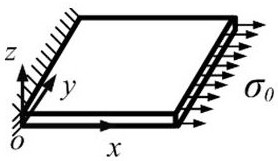

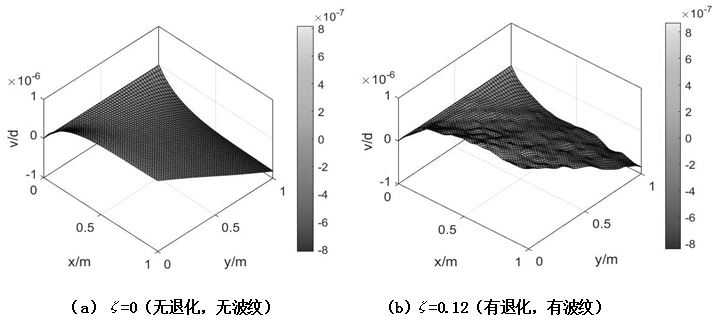

The invention discloses a tensile micro-stress detection method for performance degradation of fiber-reinforced composite materials. Deformation; the tensile load includes uniform tensile load and concentrated tensile load; 2) under the tensile load, detect whether there are wrinkles in the out-of-plane displacement of the composite material specimen, and correlate randomly according to the amplitude and density of the wrinkles. Normal Distribution Model Parameters z value, to obtain the distribution statistical information of the mechanical properties of the composite material specimen along the main direction of the fiber; 3) under the tensile load, detect whether there are ripples in the in-plane displacement of the composite material specimen perpendicular to the tensile direction, according to the amplitude of the ripples and The density is associated with the random normal distribution model parameter ζ value to obtain the distribution statistical information of the mechanical properties of the composite material specimen along the main direction of the fiber. The invention can quickly make effective prediction and evaluation on structural performance and service behavior.

Description

A tensile microstress detection method for the performance degradation of fiber-reinforced composite materials technical field [0001] The present invention relates to the field of detection methods for the performance degradation of fiber-reinforced composite materials. Background technique Fiber reinforced composite material structure has high specific strength, large specific modulus, corrosion resistance, and is not easy to produce fragments when damaged, etc. [0002] It has obvious advantages and is widely used in aerospace, automobile and ship, construction engineering, high-end sports equipment and other fields. It has good performance and light weight. It can improve the seismic performance while reducing its own weight. In the future, it will replace traditional metals such as steel more widely. Industrial materials, with broad development prospects. [0003] The processing technology of the fiber-reinforced composite material structure is relatively complicated...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N3/08G01N3/06

CPCG01N3/08G01N3/068G01N2203/0003G01N2203/0017G01N2203/0075G01N2203/0641G01N2203/0682

Inventor 马利韩九林

Owner HANGZHOU JIANTU TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com