Bending microstress detection method of fiber-reinforced composite material performance degradation

A composite material and fiber-reinforced technology, applied in the direction of applying stable bending force to test material strength, analyze material, strength characteristics, etc., can solve the problem of varying severity of defect damage, limited role of response analysis and life prediction, defect characteristics Problems such as size dispersion, to achieve the effect of rapid prediction and evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

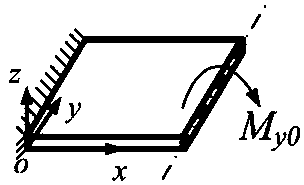

[0035] When the macroscopic elastic properties of the main fiber direction are reduced, the structure will exhibit an unconventional special response mode under a specific load. Taking composite laminates as an example, such as figure 1 As shown, this particular load is a bending load M y0 .

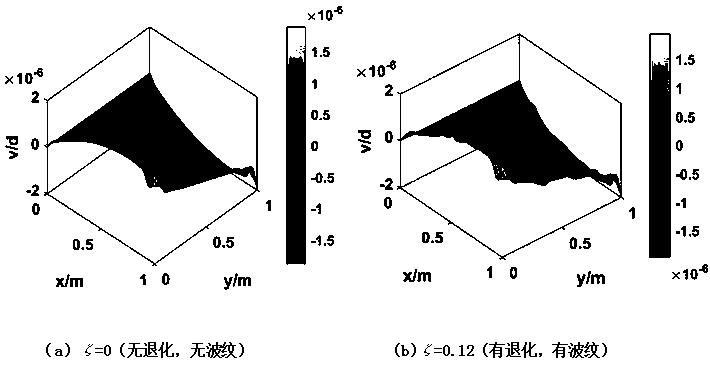

[0036] When the strength of the laminate is damaged along the main direction of the fiber, a bending load is applied to the laminate M y0 , the laminate along y The in-plane displacement in the axial direction will produce corrugations, and the denser the corrugations, the larger the corrugation amplitude, indicating that the strength along the main direction of the fiber is more damaged. For comparison, figure 2 gives a comparison, figure 2 middle z The values are the standard deviations of the elastic constants relative to the main fiber directions from their mean. z =0 means ideal material without any performance degradation. z The larger the value, the more serious the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com