Method for predicting residual life of grinding roller bearing of coal mill

A life prediction and coal mill technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve potential safety hazards, without studying the service life prediction model of grinding roller bearings, and without analyzing the characteristics of bearing failures To achieve the effect of improving safe and stable operation, good degradation trend prediction ability, and realizing fault diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

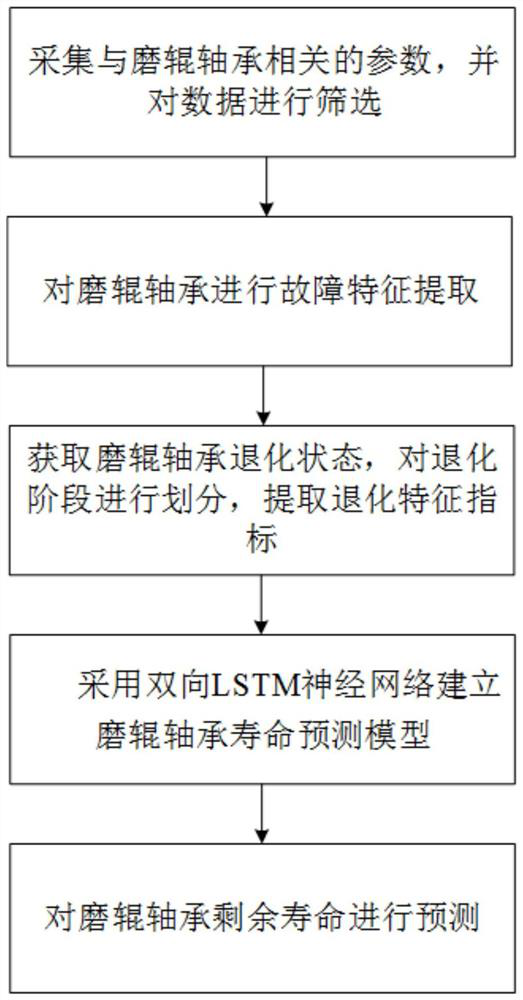

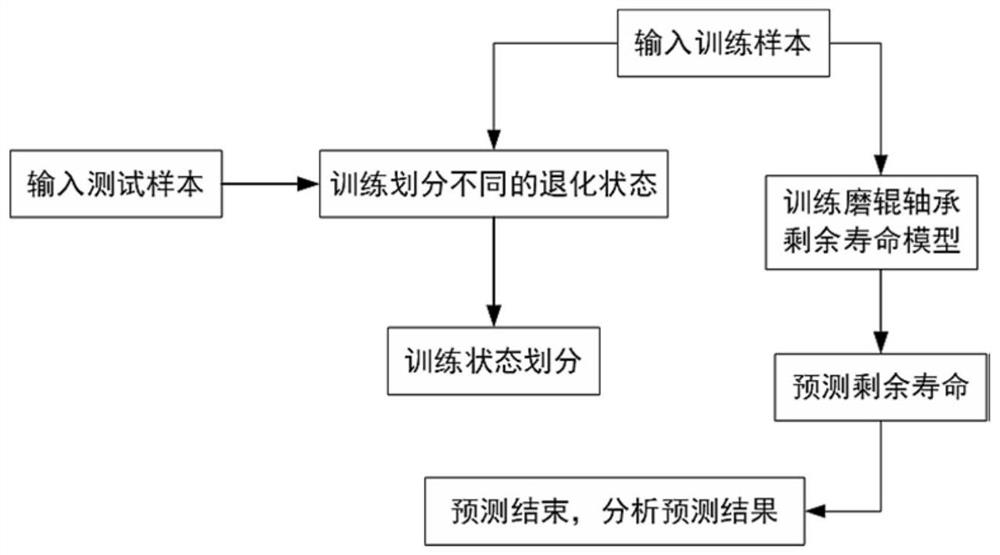

[0039] The invention relates to a method for predicting the remaining life of a grinding roller bearing of a coal mill. The method includes the following steps:

[0040] Step 1: Measure the parameters related to the vibration of the grinding roller bearing through the sensor, and filter the collected real-time data.

[0041] The parameters related to the vibration of the grinding roller bearing mainly include the temperature of the grinding roller bearing, the rotational speed of the bearing, the vibration amplitude of the bearing, etc.; for real-time data screening, the method of measuring point trend is used to process the abnormal data, that is, to view the historical data of each measuring point Trend changes, and if the collected data points deviate significantly from the statistical characteristics of the majority of data, they are removed.

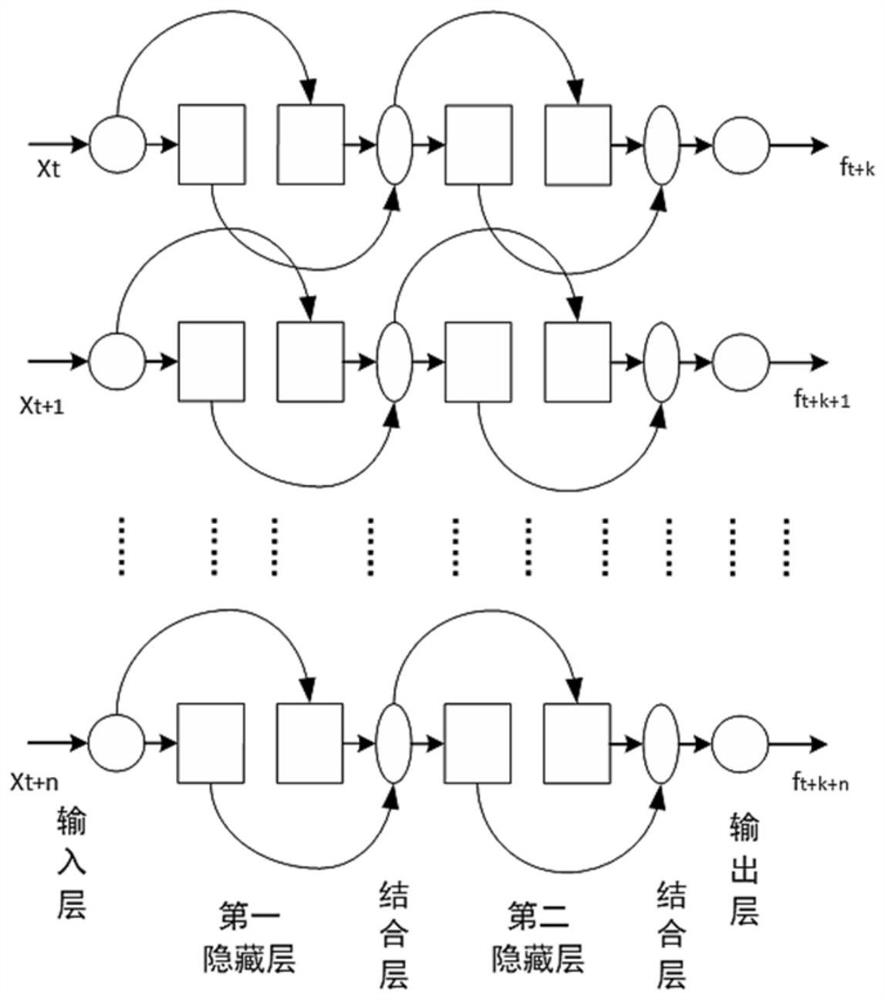

[0042] Step 2: Use VMD and entropy method to extract the fault features of the roller bearing, and select the optimal resonance fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com