Positioning block, optical positioning system based on positioning block, optical positioning method based on positioning block, and functional module

An optical positioning and positioning block technology, applied in the optical field, can solve the problems of wasting time and energy, consuming a lot of work, and the system is not repeatable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

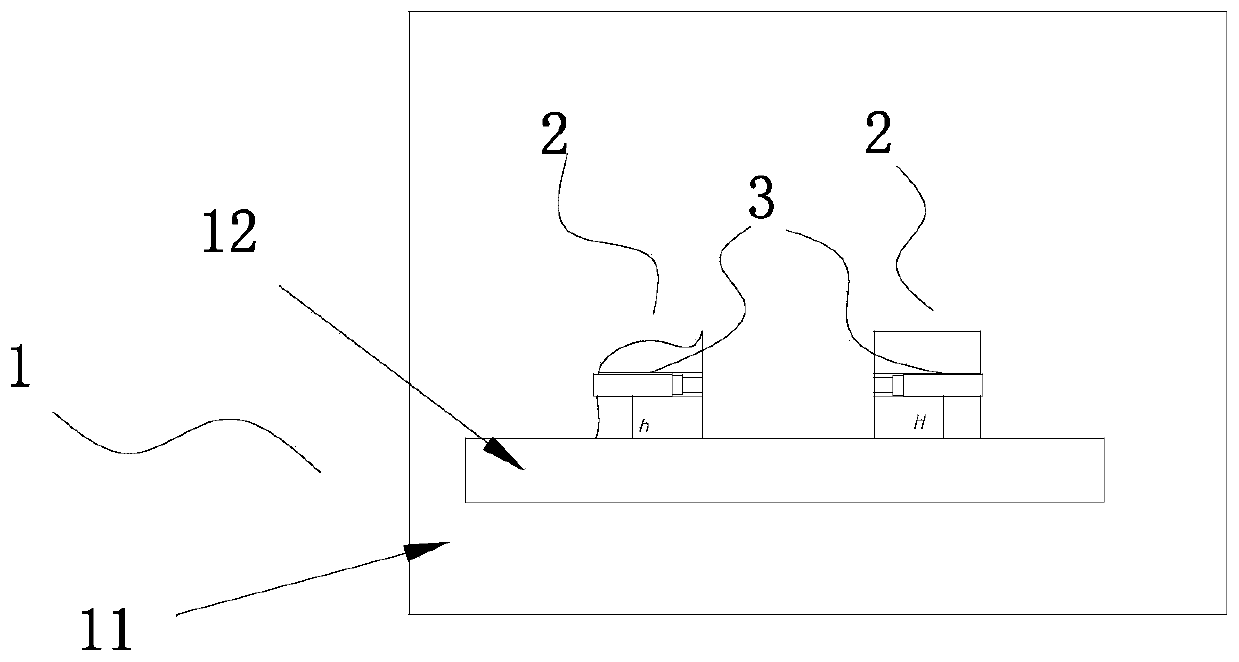

[0046] like figure 1 and figure 2 , an optical positioning system based on positioning blocks. It includes a positioning disc 1 and two positioning blocks 2 for positioning. The positioning plate 1 is composed of a bottom plate 11 with a horizontal upper surface and a straight inner side as a positioning side body 12; the block 2 includes a bottom surface and a positioning side, and the upper surface is used for carrying optical components. The optical components in this embodiment is the collimator.

[0047] The positioning method using the positioning system of the present embodiment is: take the base plate 11 of the positioning plate 1 as the positioning reference in the vertical (height) direction, and take the positioning side of the body 12 on the base plate 11 as the positioning reference in the horizontal direction. The bottom surface of the positioning block fits with the base plate 11 and the upper surface to realize the positioning in the vertical direction; the...

Embodiment 1-2

[0050] Present embodiment has no accompanying drawing, can refer to embodiment 2-2 Figure 5 .

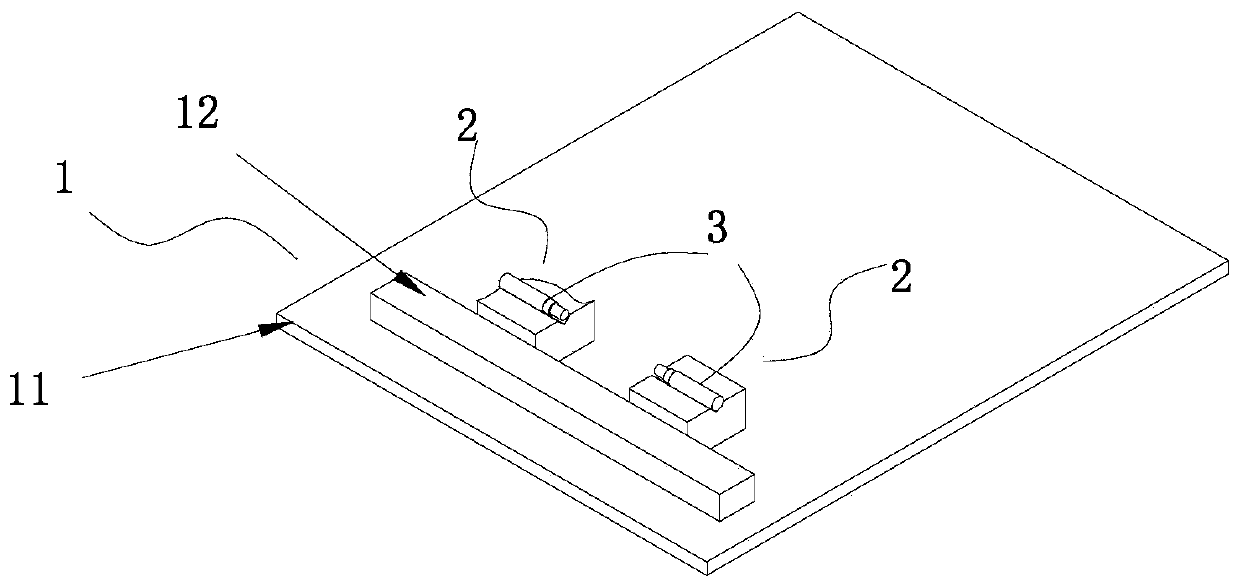

[0051] In the present embodiment, the body and the base plate are inseparable. The difference from the embodiment 1-1 is that a movable carrier 3 is added on the bottom plate, and one side of the carrier 3 is attached to the positioning side of the leaning body 12 . The bottom surface of the positioning block 2 is attached to the carrier board 3 .

[0052] In this embodiment, the positioning plate 1 adopts non-magnetic material, and the carrier plate 3 adopts magnetic material, so that the block 2 and the carrier plate 3 are adsorbed as a whole, but not adsorbed with the positioning plate, so that the carrier plate 3 and the block 2 and The optical functional components are moved out of the positioning plate as a whole to form an independent functional module. Glue can also be used to fix the positioning block 2 and the carrier plate 3, and the carrier plate 3, the block 2 and t...

Embodiment 2-1

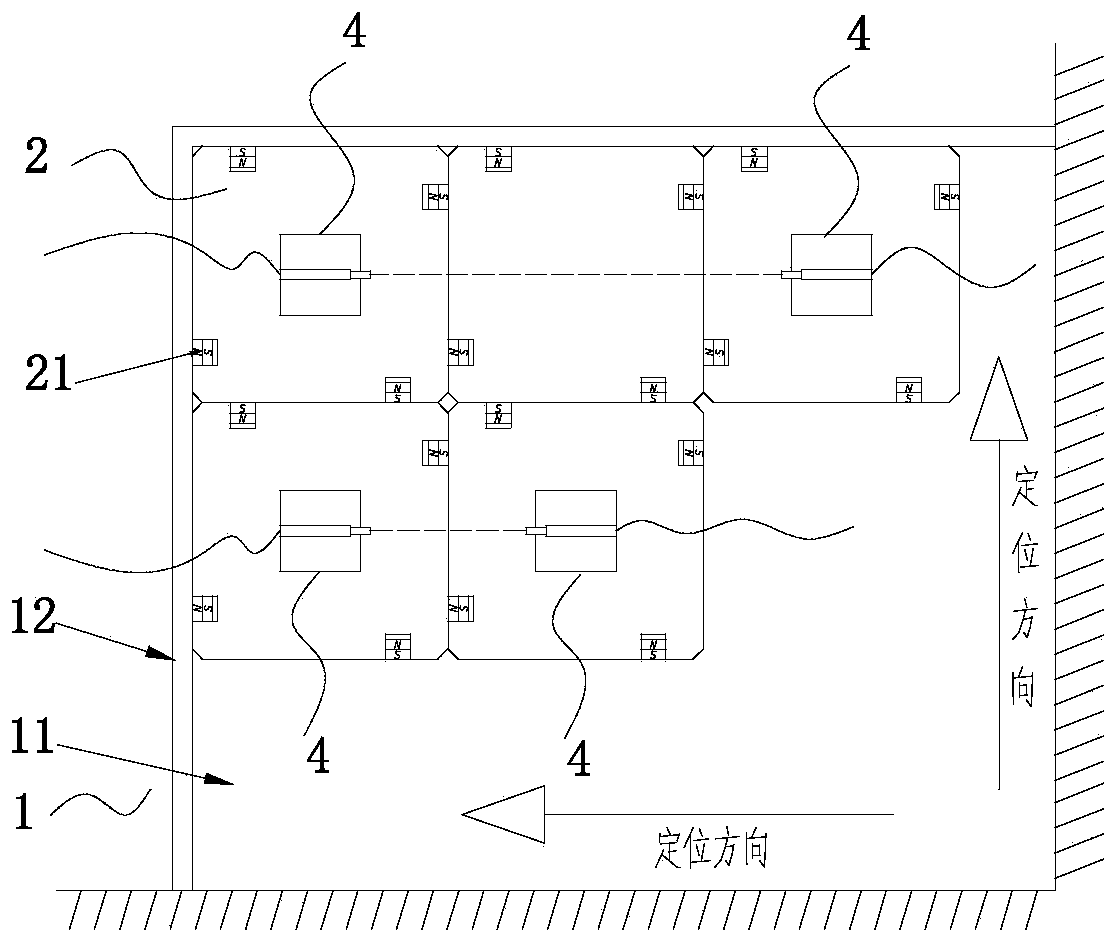

[0054] like image 3 and Figure 4 , an optical positioning system based on positioning blocks. It includes a positioning plate 1 and several blocks 2 for positioning. Positioning plate 1 is made of the base plate 11 of upper surface level and the straight inner side body 12 that is perpendicular to each other; The plane of each block 2 in the figure is the square of the same size, and the plane size can also be designed by modularization, that is, the plane size is as follows: A square with the minimum side length is the basic unit, and a rectangle or square whose length or width is an integral multiple of the minimum side length can be designed.

[0055] Block 2 adopts magnetic stainless steel or other magnetic materials, and is integrally processed and formed. Each side of the cube 2 is embedded with a magnet 21 . The position of the magnets 21 avoids the middle position, and is unified to the left or to the right, and the polarity directions of the embedded magnets 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com