A magnetic bonding process for small NdFeB tapes

A neodymium-iron-boron and process technology, which is applied in the field of magnetic bonding process of small neodymium-iron-boron tapes, can solve the problems of high cost, affect production efficiency, and unsaturated magnetization, and achieve efficiency improvement, production efficiency improvement, and sound pressure increase. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

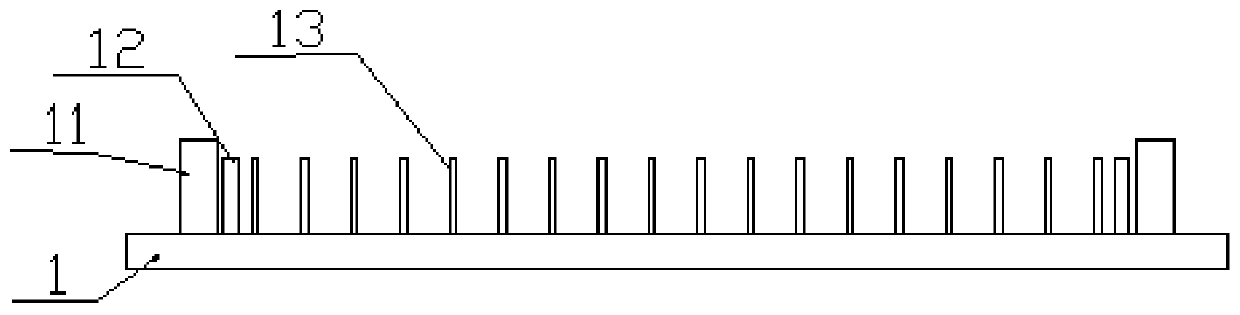

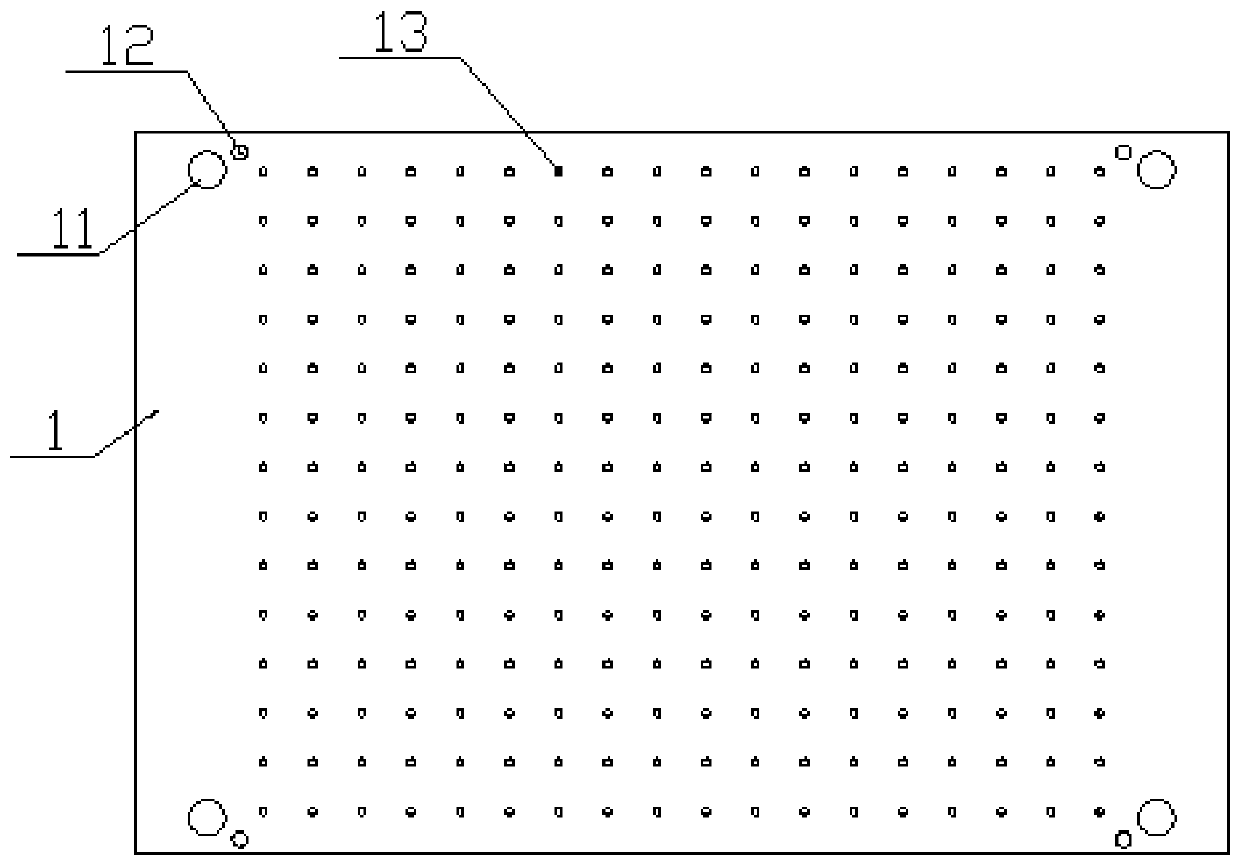

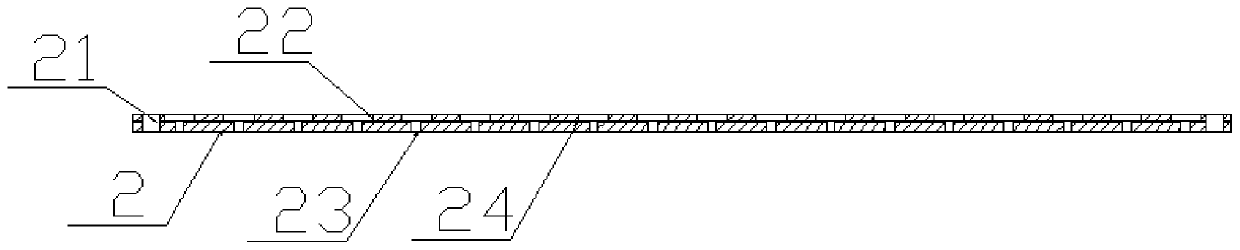

[0046] The diameter of the magnetic sheet 6 is 14 mm, the height is 4 mm, the diameter of the iron sheet is 14 mm, and the height is 2 mm. The magnetic sheet plate 2 is designed, and the distance between every two magnetic sheet grooves 22 is designed at 12-13 mm, which can ensure that the magnetic sheet 6 is scraped into When in the magnetic sheet groove 22, can not attract each other because the distance is too close, and the magnetic sheet plate 2 is compounded with an iron plate-24 simultaneously, and the magnetic sheet 6 can be firmly sucked in the magnetic sheet groove 22.

[0047] Place the magnetic plate 2 on the workbench 1, pre-position the magnetic plate 2 through the limit post 11, and insert the limit post 2 12 into the limit hole 21 of the magnetic plate to realize the positioning of the magnetic plate 2. Precise positioning ensures that the ejector pin 13 can be aligned and passes through the ejector pin hole 23 of the magnetic plate. The adhesive plate 3 is rev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com