Filter press capable of automatically clearing filter residues and use method

An automatic cleaning and filter press technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of easily damaged filter cloth, increased cost, time-consuming and laborious, etc., to avoid time-consuming and laborious, prevent external leakage, Guaranteed filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

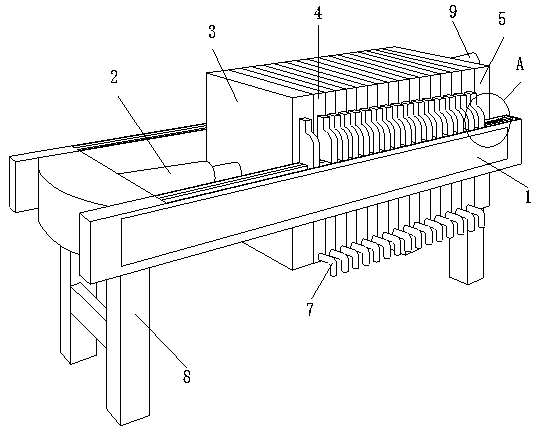

[0019] as attached Figures 1 to 8 As shown, a filter press for automatically cleaning filter residues includes a beam 1, a pusher 2, a pressing plate 3, a thrust plate 5, a separation mechanism 6 and a frame 8, and two symmetrically fixed frames are fixed on the top of the frame 8. A beam 1, a pusher 2, a compression plate 3 and a thrust plate 5 are installed in sequence from left to right between the two beams 1, and the compression plate 3 can be horizontally moved along the beam 1 through the pusher 2 and the separation mechanism 6. To move, the separation mechanism 6 is installed on the upper surface of the beam 1 .

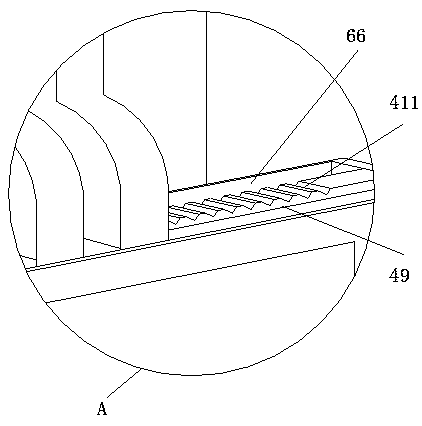

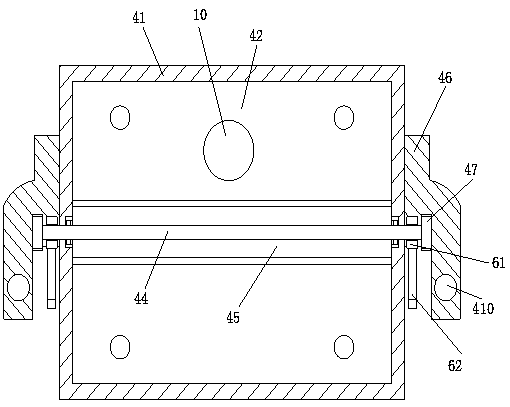

[0020] as attached Figures 2 to 5 As shown, there are also several cleaning mechanisms 4 assembled on the beam 1 between the pressing plate 3 and the thrust plate 5. The cleaning mechanism 4 includes a filter frame 41, a filter plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com