Multipurpose supercritical fluid device

A multi-purpose, heat-preserving fluid technology, applied in processes under supercritical conditions, pressure vessels used in chemical processes, and methods of chemically changing substances by using atmospheric pressure, and can solve problems such as inapplicability to high-pressure devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

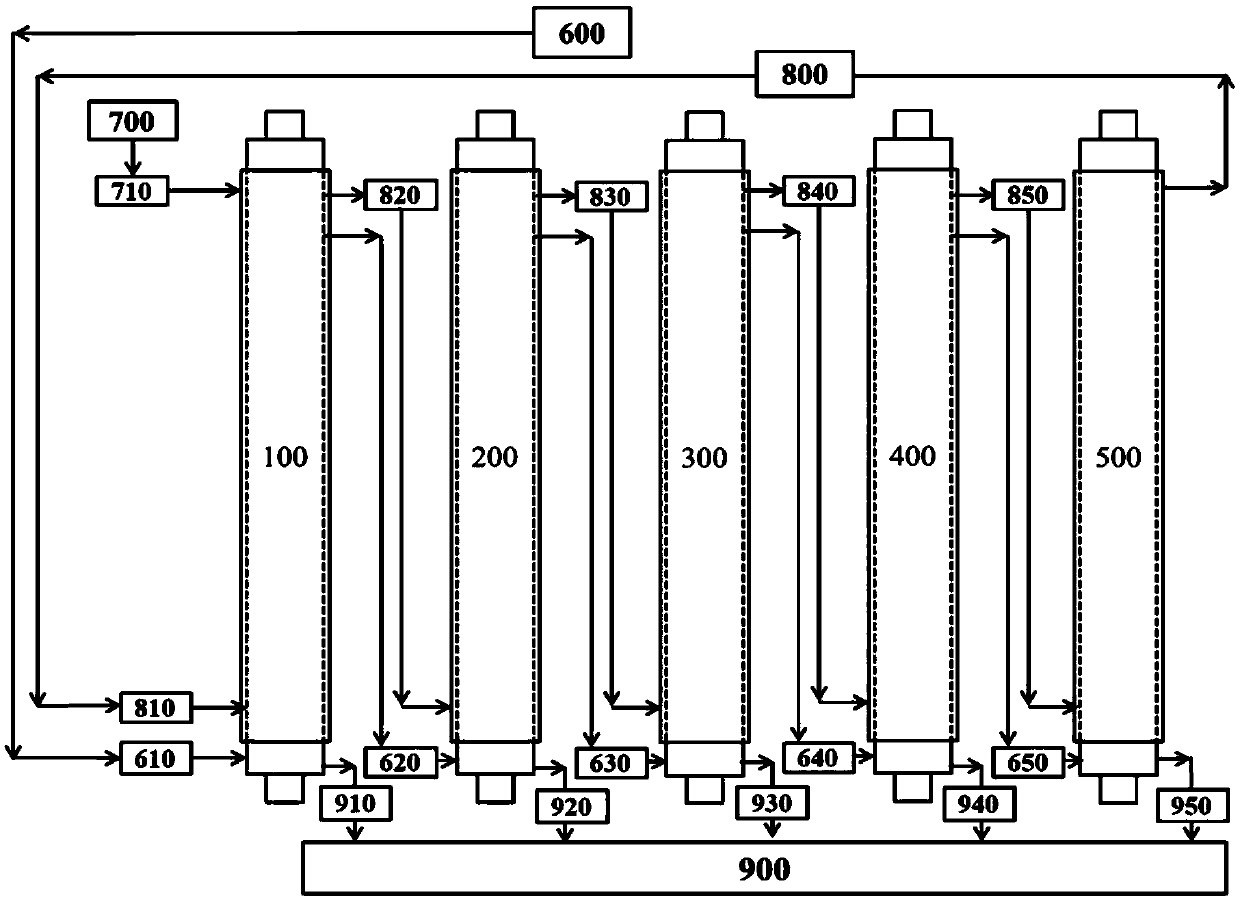

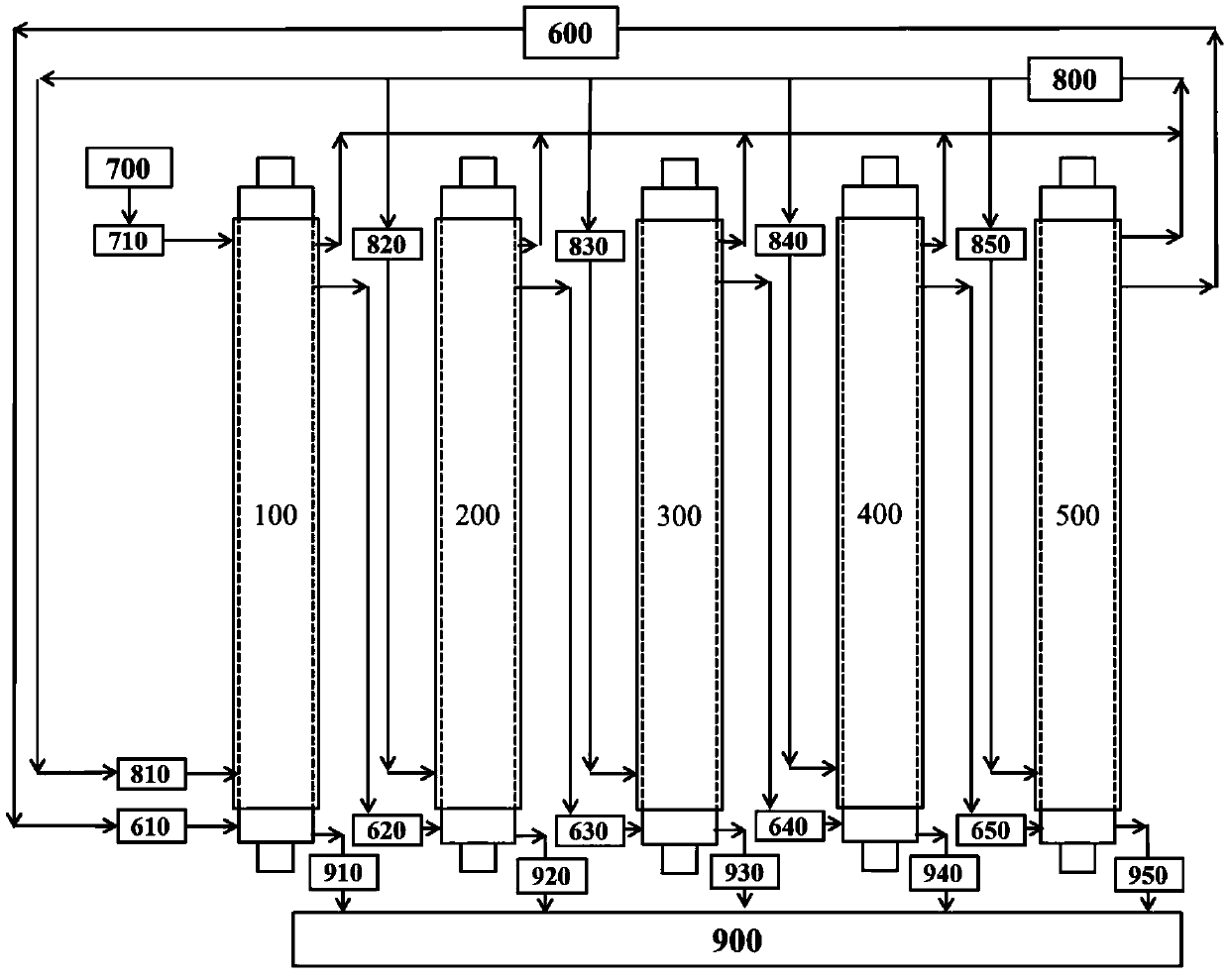

[0125] figure 1 Among them, 100 is the first SCF tank, 200 is the second SCF tank, 300 is the third SCF tank, 400 is the fourth SCF tank, 500 is the fifth SCF tank; 600 is the SCF control component, which passes The first SCF connection assembly 610 is connected to the first SCF tank body 100, and the first SCF tank body 100 and the second SCF tank body 200 are connected in series through the second SCF connection assembly 620, and the second SCF tank body 200 is connected in series through the third SCF connection assembly 630. The SCF tank 200 and the third SCF tank 300 are connected in series to the third SCF tank 300 and the fourth SCF tank 400 through the fourth SCF connection assembly 640 , and the fourth SCF tank 400 is connected in series through the fifth SCF connection assembly 650 and the fifth SCF tank 500, that is to say, the SCF control assembly 600 and the first SCF tank 100, the second SCF tank 200, the third SCF tank 300, the fourth SCF tank 400, and the fift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com