a double bi 4 o 5 i 2 Preparation method of photocatalytic material and its application in degrading mc-lr

A catalytic material and visible light technology, applied in the direction of organic compound/hydride/coordination complex catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of light absorption of unfavorable composite photocatalytic materials and shrink heterojunction Response range, poor photocatalytic activity and other problems, to achieve the effect of improving photocatalytic activity, facilitating the transport of photogenerated carriers, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

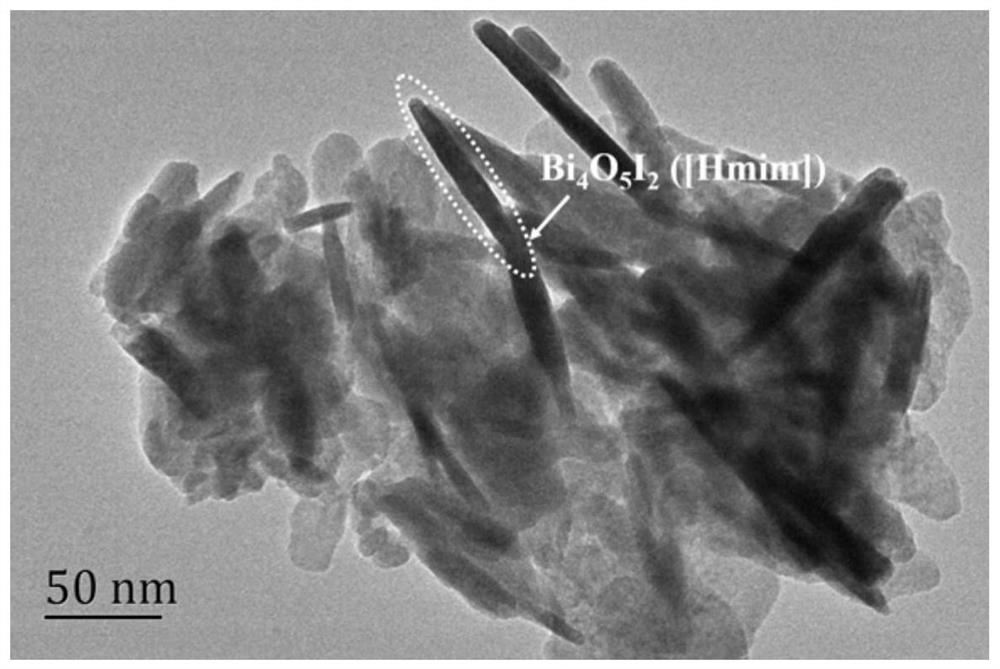

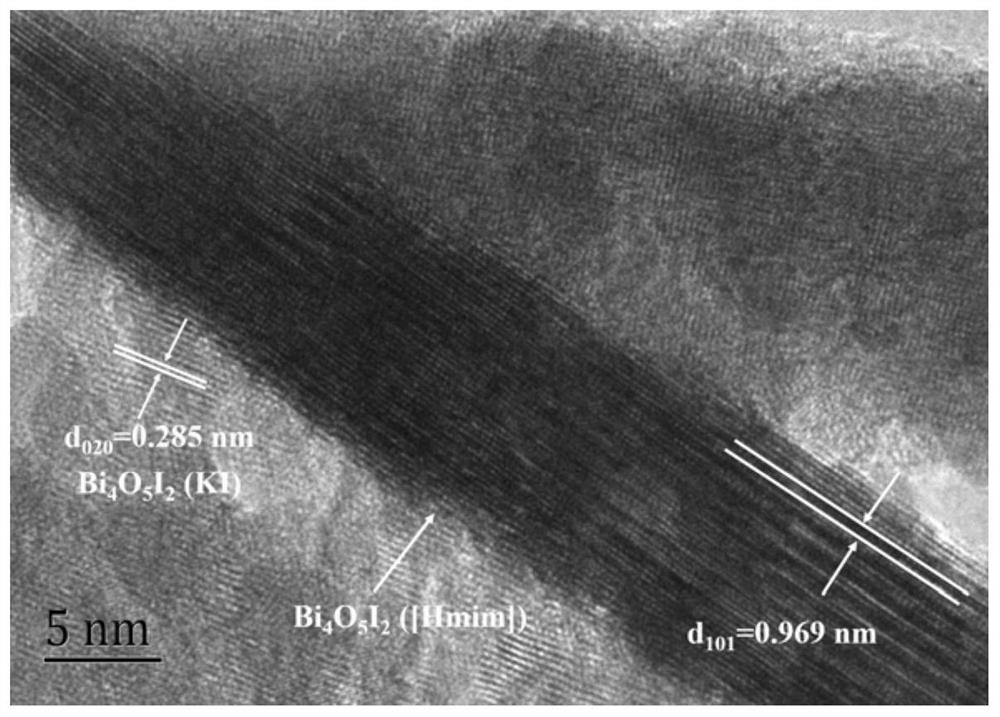

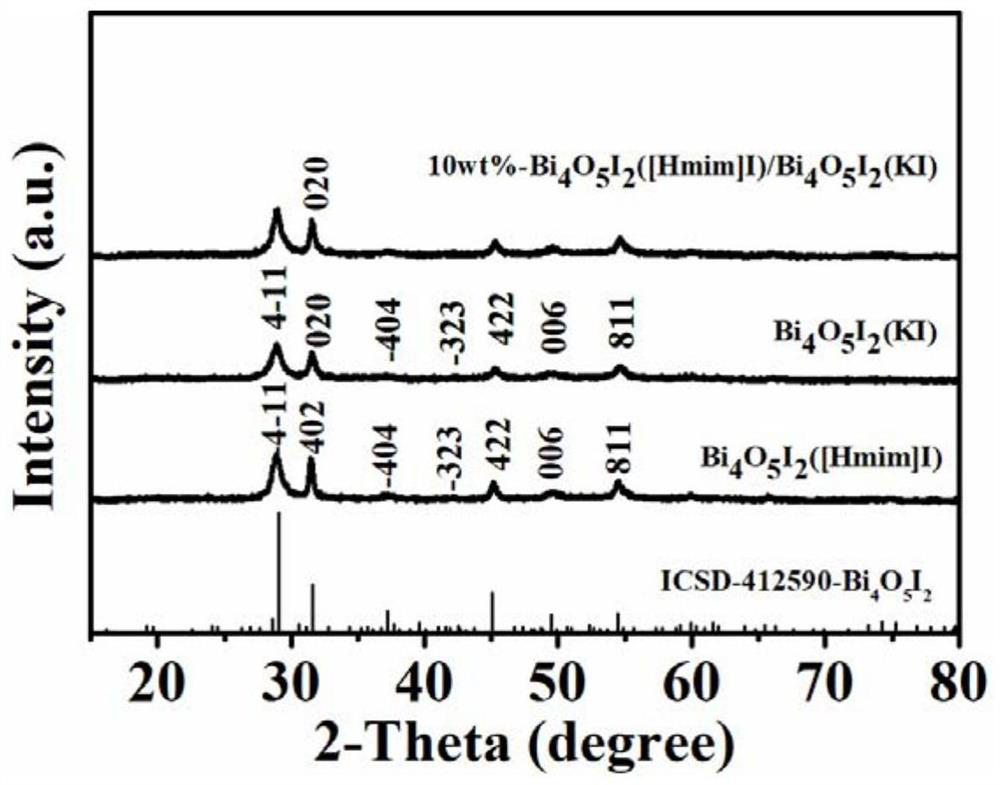

[0033] Preparation of Bi 4 o 5 I 2 (KI) Precursor of catalytic material: weigh 2mmol of Bi(NO 3 ) 3 ·5H 2 O was dispersed in 20 mL of glycerol, 2 mmol of KI was dissolved in 20 mL of glycerol, and then the KI solution was added dropwise to Bi(NO 3 ) 3 ·5H 2 In the O solution, keep stirring to obtain a uniformly dispersed bright orange-red liquid, which is poured into a polytetrafluoroethylene-lined reactor for solvothermal reaction (160 ° C, 16 h), then naturally cooled to room temperature, centrifuged , washed alternately with absolute ethanol and deionized water for 3 to 4 times, and finally freeze-dried at -62°C for 1 h to obtain a dark yellow, powdery precursor.

Embodiment 2

[0035] Preparation of Bi 4 o 5 I 2 (KI): Weigh 0.3g of the above precursor into a beaker filled with 200mL deionized water, put the beaker into an oil bath, and after 24 hours of hydrolysis reaction at low temperature (45°C), the color of the solution changes from dark yellow to bright orange Yellow, then washed with deionized water for 3 to 4 times, and finally dried at 80°C for 10 hours to obtain bright orange, powdery Bi 4 o 5 I 2 (KI).

[0036] Bi 4 o 5 I 2 (KI) specific surface area (62.32m 2 / g), the maximum absorption wavelength is 515nm, and the photocatalyst has good stability (5 cycles of experiments, no significant reduction in photocatalytic activity).

Embodiment 3

[0038] Bi 4 o 5 I 2 ([Hmim]) I) preparation: take by weighing 0.0485g Bi(NO 3 ) 3 ·5H 2 O was dispersed in 20mL mannitol solution (0.1M), magnetically stirred and dispersed uniformly to form a mixed solution A, and then 0.029g ionic liquid [Hmim]I (1-hexyl-3-methylimidazolium iodide) was weighed and dissolved in 20mL mannitol Form solution B in alcohol solution (0.1M), then add solution B dropwise to solution A, keep magnetic stirring during the dropping process and extend magnetic stirring for 30min, then adjust the pH of the mixed solution with sodium hydroxide solution (1M) =10.5, continue to maintain magnetic stirring for 30min, transfer the mixed solution to a 50mL polytetrafluoroethylene-lined reactor for solvothermal reaction (140°C, 20h), let it stand for 5h after natural cooling, pour off the supernatant, and use Alternately wash the mixture with water, ethanol and deionized water for 4 times, and finally dry the sample in a blast drying oven at 60°C for 12 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap