SLM molding system with bidirectional powder laying function

A function and powder spreading technology, which is applied in the field of laser selection and melting SLM molding equipment, can solve the problems of low powder feeding efficiency and low molding efficiency, and achieve the effect of saving resources and improving powder spreading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

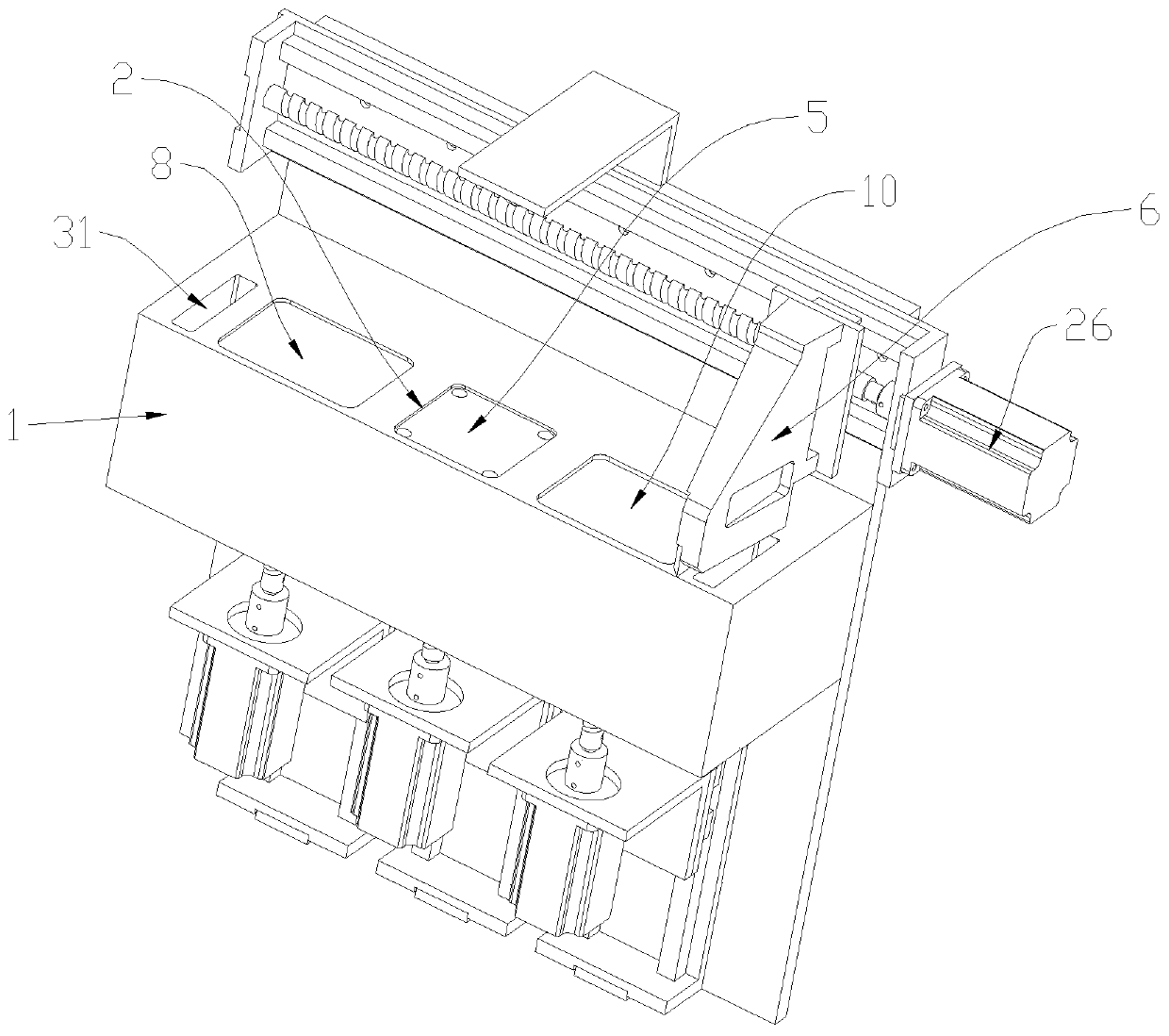

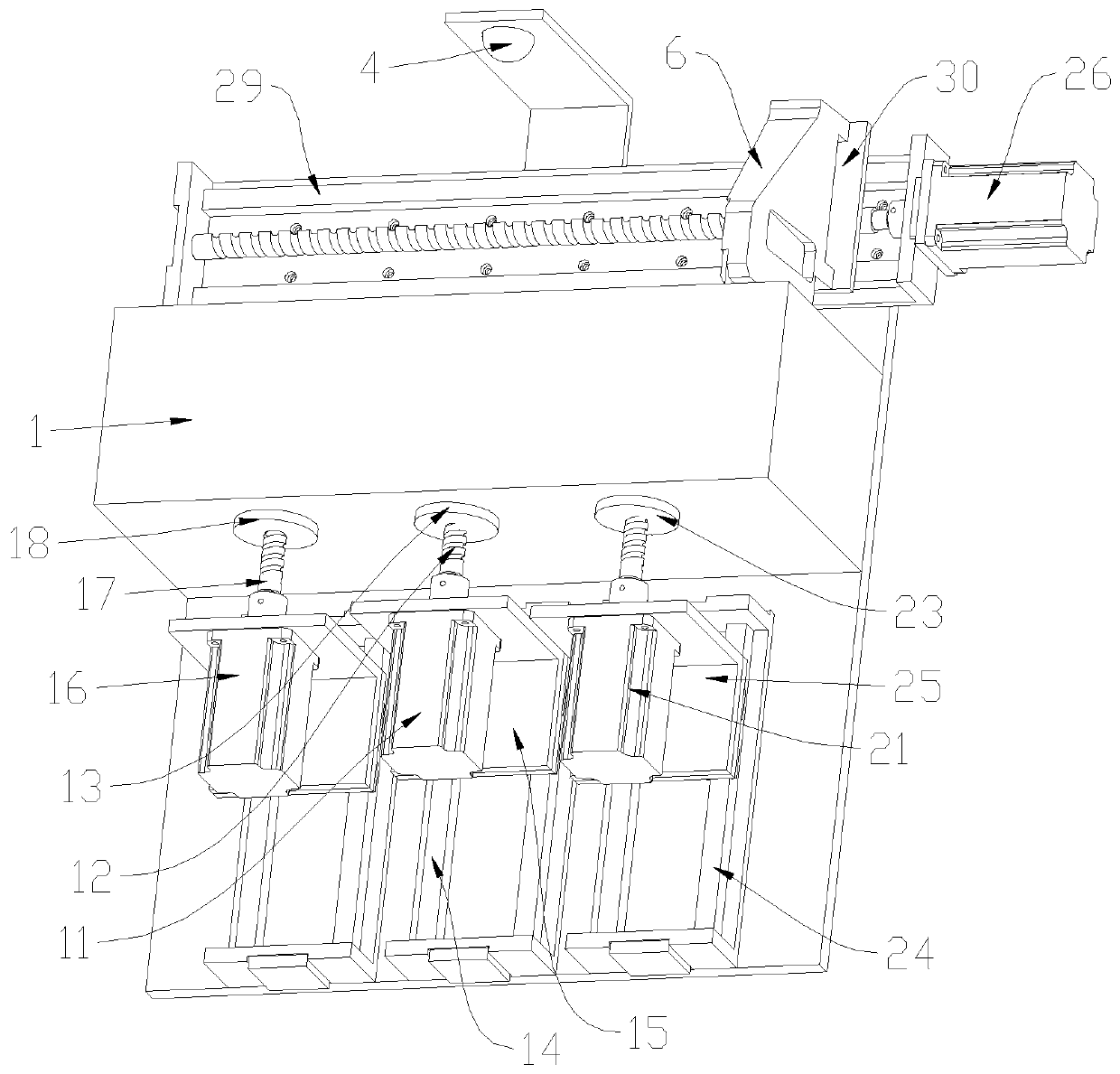

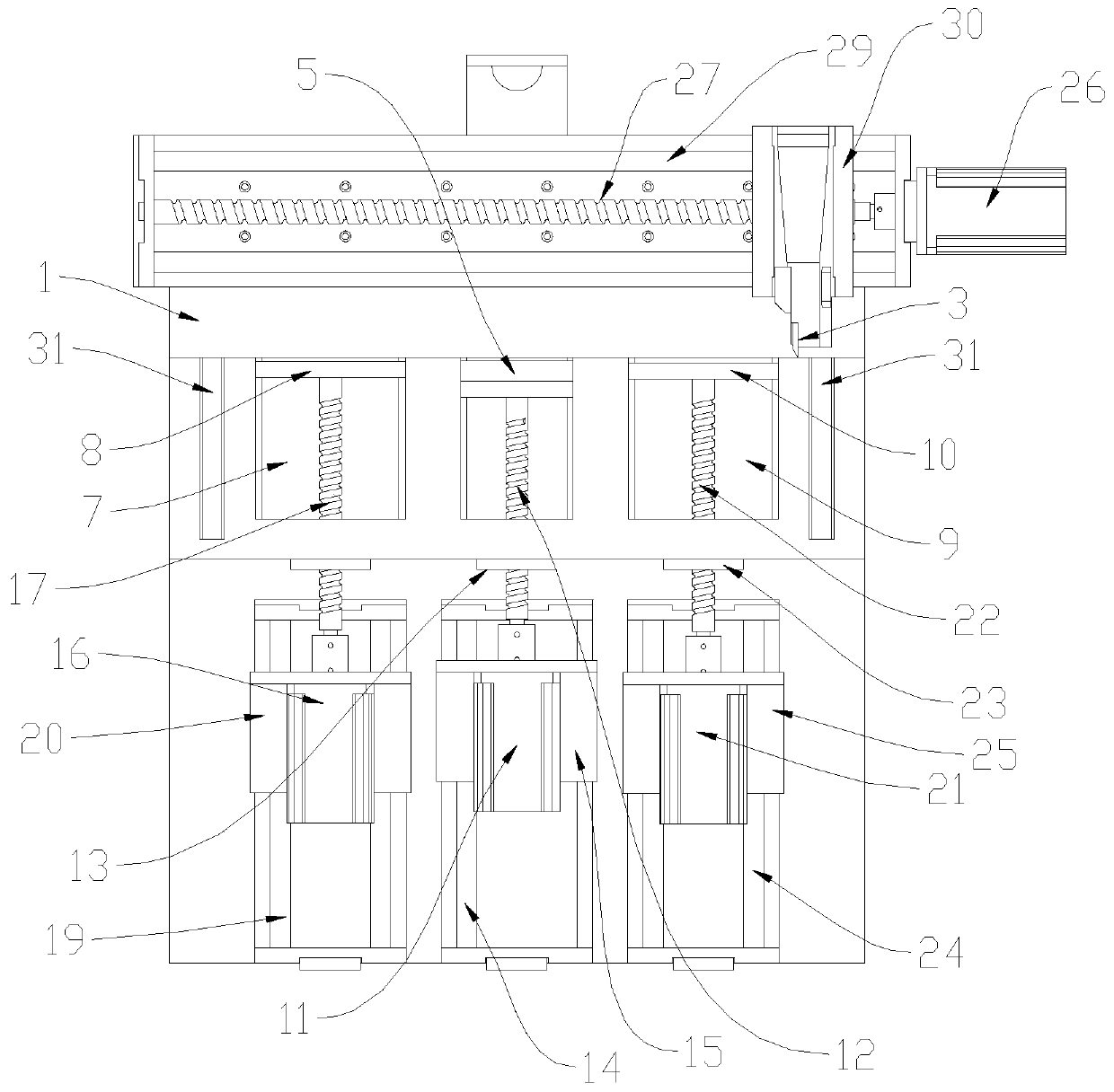

[0025] see Figure 1 to Figure 4 , a SLM molding system with two-way powder spreading function, including a body 1, a molding cylinder 2, two powder feeding mechanisms and a scraper 3 reciprocating between the two powder feeding mechanisms are arranged on the body 1, and the molding cylinder 2 is located Between the two powder feeding mechanisms, there is a laser head 4 above the molding cylinder 2. The laser head 4 is used for laser sintering and molding the powder on the molding cylinder 2. A molding platform 5 is installed on the molding cylinder 2 to drive the molding platform 5 up and down. The first lifting mechanism, the scraper 3 is movably arranged on the body 1 through the scraper frame 6, wherein the scraper 3 is arranged at the bottom of the scraper frame 6, and the blade of the scraper 3 is in contact with the plane of the machine body 1, and the scraper 3 is used The powder on the two powder feeding mechanisms is scraped and sent to the molding platform 5, wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com