Inner mould matching assembly

A component and inner mold technology, applied in the direction of mold auxiliary parts, molds, mold fixing devices, etc., can solve the problems of inconvenient processing, troubles, and inability to replace the inner mold of the pipe gallery, and achieve exquisite structure, good stability, and accurate fit installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

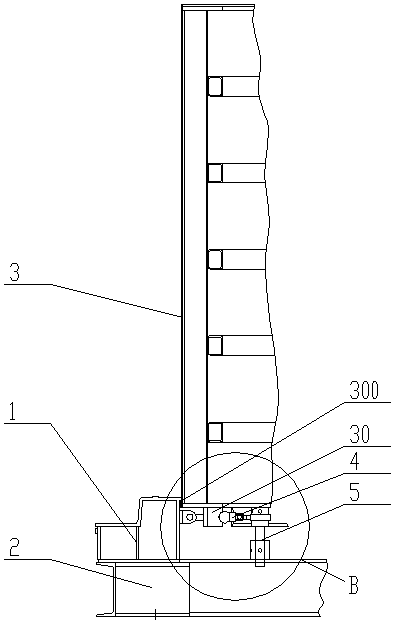

[0021] The present invention as Figure 1-3 As shown, the mold of the integrated pipe gallery includes an outer mold, an inner mold and a bottom mold, and the bottom mold includes an annular boss 1 and a base 2 that are integrated from top to bottom, and the inner mold 3 fits On the inner surface of the annular boss 1, the outer mold fits on the outer surface of the annular boss; thereby forming an inner surface of the outer mold, the top surface of the annular boss and the outer surface of the inner mold It is used for pouring concrete to form the mold cavity of the comprehensive pipe gallery.

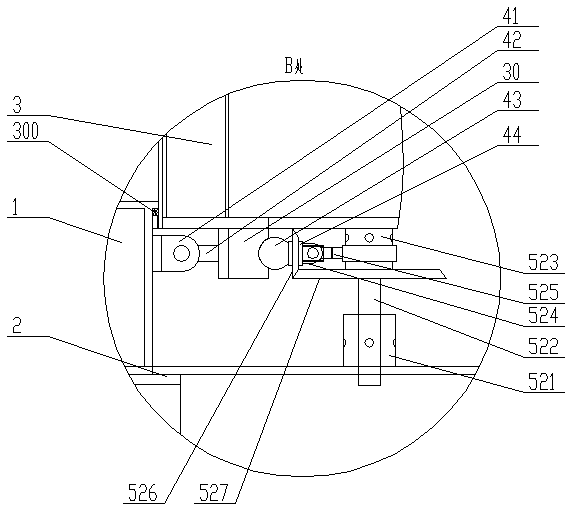

[0022] The mold installation system includes a block 30 fixedly connected to the bottom surface of the inner mold 3 and a pressing mechanism 4 arranged on the inner surface of the annular boss 1;

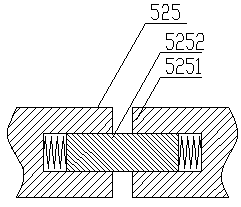

[0023] Described pressing mechanism 4 comprises hinge base 41, screw rod 42, slide block 43, nut 44 and lifting support mechanism 5, and described hinge base 41 is fixedly connected on the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap