Motor jump ring plugging equipment

A circlip and equipment technology, which is applied in the field of motor circlip insertion equipment, can solve problems such as low efficiency, and achieve high production efficiency, stable insertion quality, and fast insertion and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

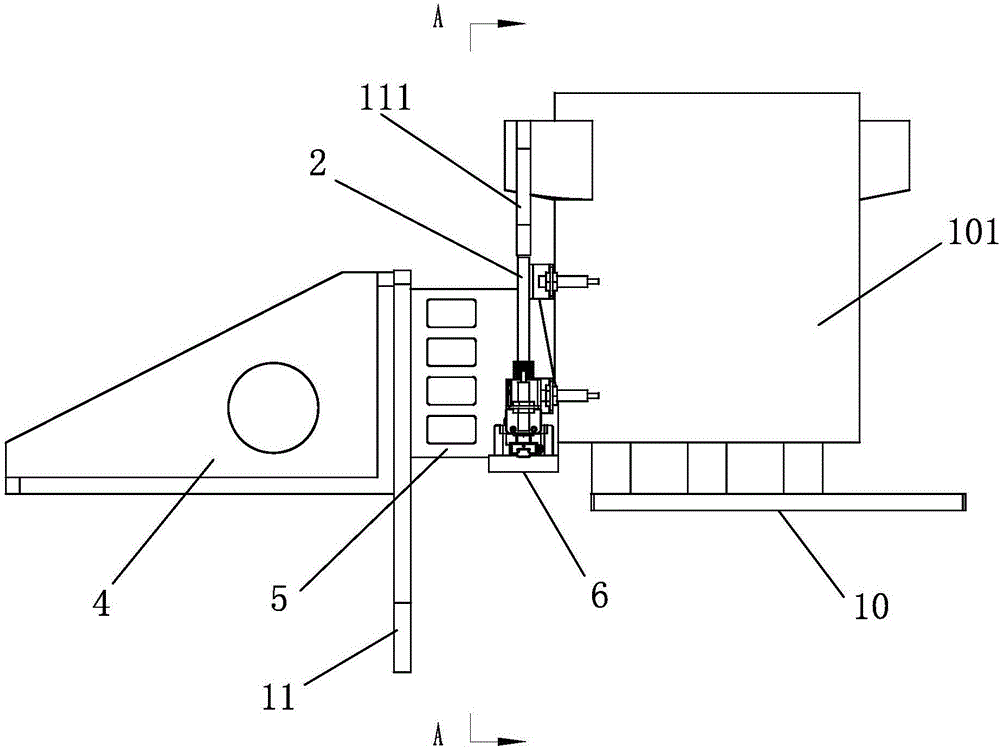

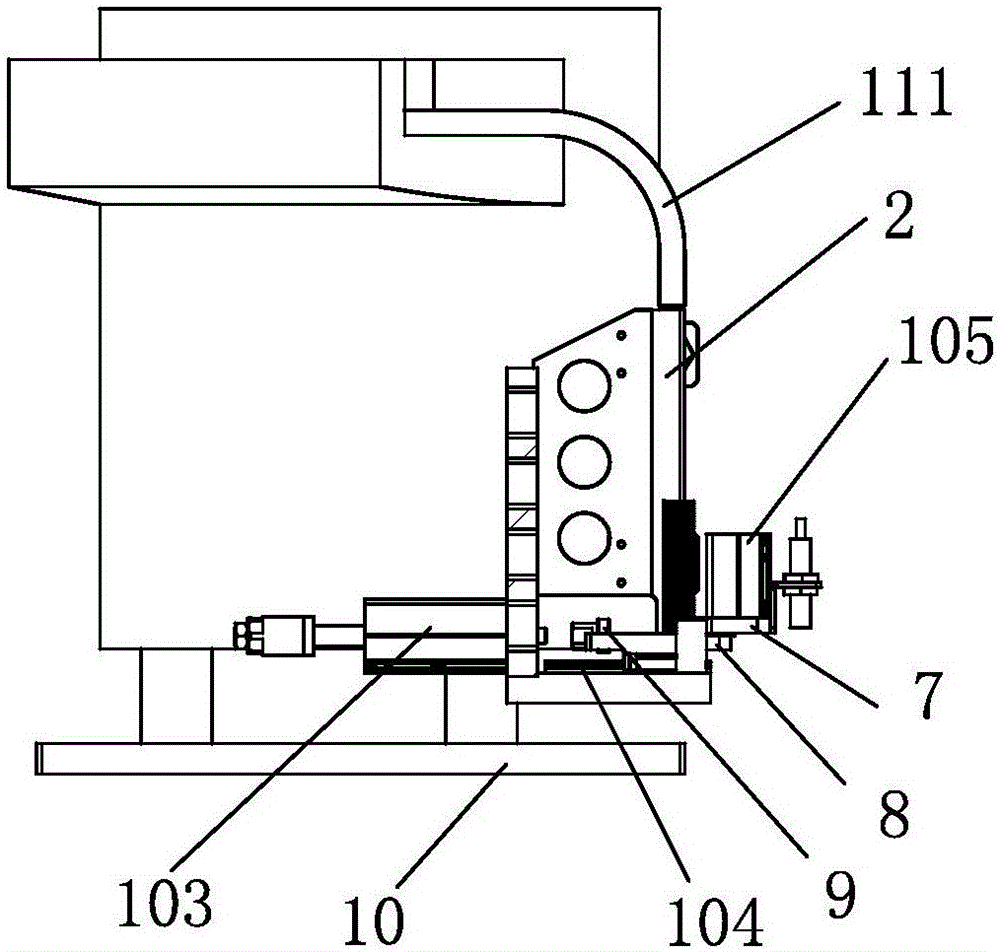

[0021] Embodiment: The motor circlip insertion device of the present invention, as attached Figure 10 As shown, it includes a frame 1001, a clip spring device 1002, a motor fine positioning device 1003, a clip spring material distribution device 1004, a visual fixing device 1005, a workpiece tray 1007, a fixed lift positioning stop 1008, and a workpiece from the frame 1001 to Side pass to the workpiece pallet 1009 on the other side.

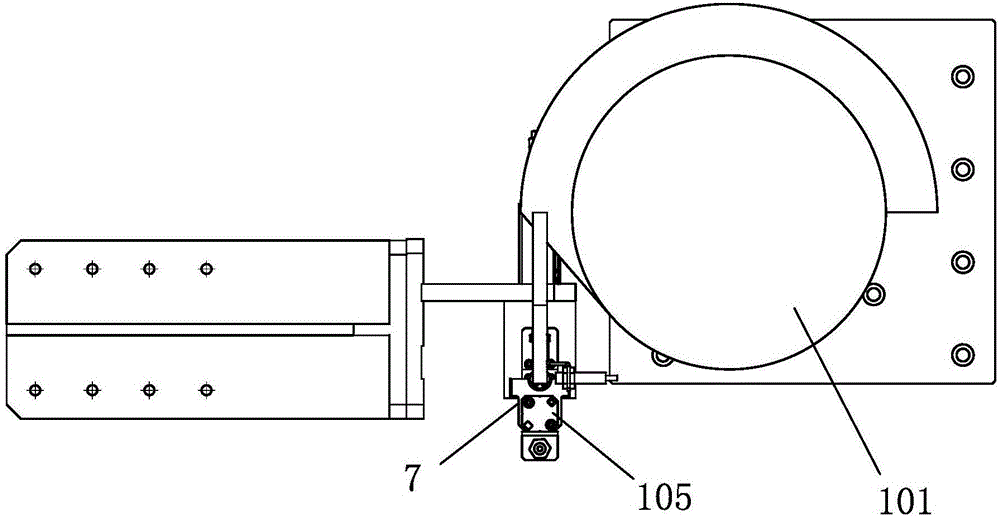

[0022] as attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 As shown, the circlip dispensing device 1004 comprises a vibrating plate 101, and the vibrating plate 101 has a guide post 111 that guides the motor circlip to move out; the outlet of the guide post 111 is provided with a circlip guide material 2; when the motor circlip is removed from the guide post When moving out on 111, be inserted on the jump ring guide member 2, and stack successively.

[0023] as attached figure 1 , attached figure 2 , attach...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap