A front bumper upper ventilation grille assembly tool and its use method

A front bumper and ventilation grille technology is applied in the field of ventilation grille assembly tooling on the front bumper, which can solve the problems of scratches, rework and scratches on the paint surface of the front bumper, ensure production tact and facilitate film replacement. , the effect of saving man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is further explained below with reference to the accompanying drawings and examples:

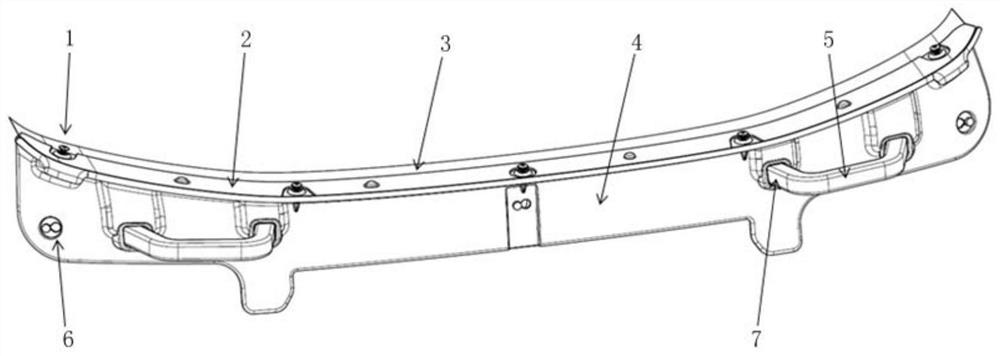

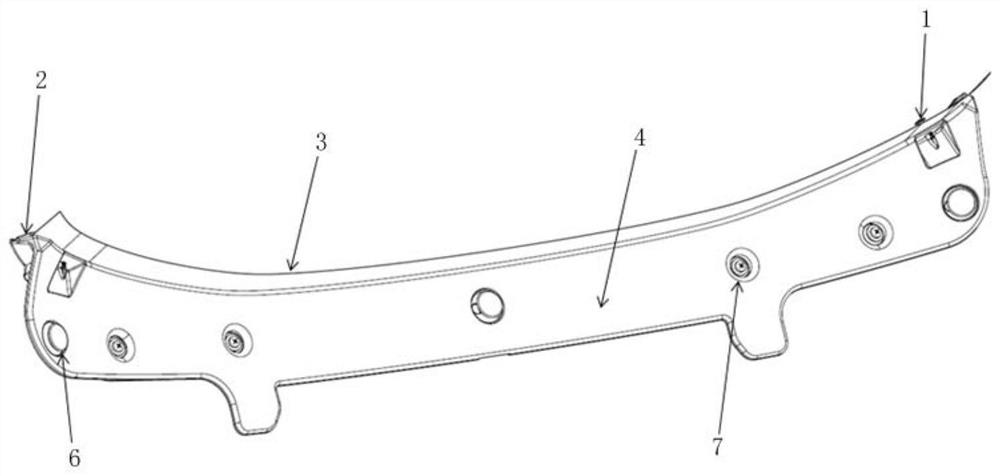

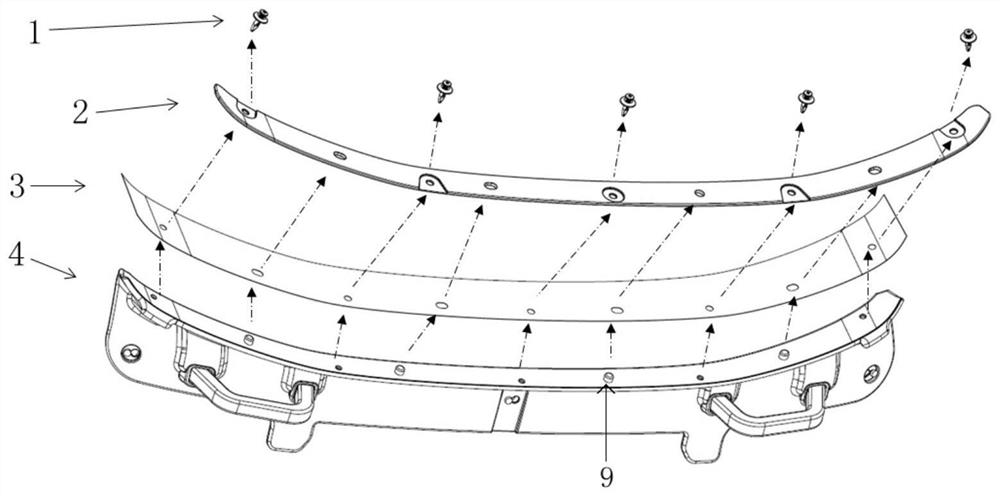

[0021] See Figure 1 - Figure 9 .

[0022] The present invention discloses a front bumper on the wind-resistant grid distribution, including a buckle 1, a fixed pressure plate 2, a film 3, a tool body 4, and the tooling body 4 matches the surface shape of the front bumper 8, said The upper portion of the tool body 4 is provided with a tooling platform 401 that extends in the inner side of the upper edge of the bumper 8 and matches the shape of the upper edge, the fixed pressure plate 2, the film 3 and the tooling platform 401 shape Matching, the fixed pressure plate 2 and the tooling platform 401 are positioned by positioning the film 3 by a positioning hole and a buckle 1, and the rear surface of the tool fixing of the film 3 is extended to the remaining amount of the fixed platen 2 and the tooling platform 401. The industrial body 4 is provided with a suction cup 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com