A kind of waterborne organosilicon anti-cracking anticorrosion coating and preparation method thereof

An anti-corrosion coating and anti-cracking technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of unapplied anti-corrosion fields, lack of anti-cracking, high price, etc., and achieve good mechanical stability, good anti-cracking performance and compactness , the effect of reducing VOC emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

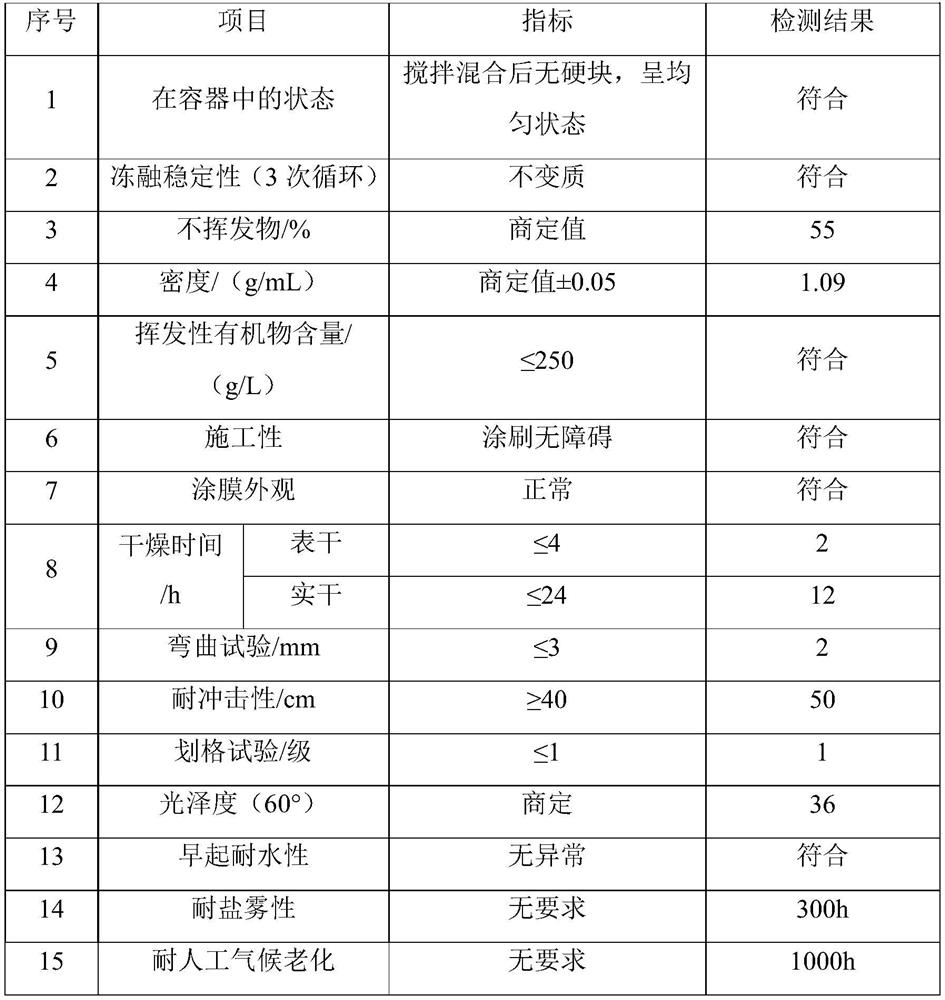

Examples

preparation example Construction

[0053] A kind of preparation of waterborne organosilicon anti-cracking anticorrosion paint, comprises the following steps:

[0054] (1) Preparation of silicone flexible emulsion,

[0055] Put polysiloxane, nano-silica, non-ionic emulsifier and simethicone oil with a viscosity of 400-2000mPa·s into a 250ml flask, stir at room temperature for 5-10min at a speed of 1500r / m, and then use ultrasonic Disperse for 10 minutes, slowly add 73g of deionized water to the dispersed material under stirring condition, the rotation speed is 1500-2000r / m, and disperse evenly to prepare a silicone flexible emulsion.

[0056] As a preference, the polysiloxane includes: α, ω-dihydroxypolydimethylsiloxane, α, ω-dihydroxypolymethylphenylsiloxane, α, ω-diethoxypolydimethicone Methylsiloxane, α,ω-Diethoxypolymethylphenylsiloxane, α,ω-Dihydroxypolydiethylsiloxane, α,ω-Dihydroxypolymethyltrifluoropropyl One or more of siloxanes, viscosity: 400-2000mPa·s.

[0057] As a preference, nano-SiO 2 It is h...

Embodiment 1

[0072] The preparation of component A of water-based silicone anti-cracking anti-corrosion coating is as follows: add 10.0 g of deionized water into a beaker, and then add dispersant: 0.2 g, defoamer: 0.3 g, rutile titanium dioxide: 5.0g, nano zinc oxide: 0.5g, sericite: 5.0g, barium sulfate: 3.0g, anti-rust filler: 10.0g, coloring pigment: 2.0g, stir well and pour into horizontal sand Grind and disperse in the mill until the fineness is less than or equal to 50μm, and add PH regulator: 0.3g, silicone flexible emulsion: 45.0g, anti-flash rust agent: 0.8g, thickener: 0.3g, adjust the viscosity of the coating to 800±200mPa·s, and filter to obtain component A of the water-based silicone anti-cracking and anti-corrosion coating.

[0073] Wherein: the preparation method of organosilicon flexible emulsion is:

[0074] The preparation of silicone flexible emulsion is as follows: 100g of polysiloxane with a viscosity of 2000mPa s, 5.0g of nano silicon dioxide, 5.0g of nonionic emulsi...

Embodiment 2

[0080] The preparation of component A of the water-based silicone anti-cracking anti-corrosion coating is as follows: add 20.0 g of deionized water into a beaker, and then add dispersant: 0.35 g, defoamer: 0.4 g, rutile titanium dioxide: 12.5g, nano zinc oxide: 1.25g, sericite: 10.0g, barium sulfate: 6.5g, anti-rust filler: 20g, coloring pigment: 6.0g, stir well and pour into horizontal sand mill Grind and disperse in the machine until the fineness is less than or equal to 50μm, and then add PH regulator: 0.45g, organic silicon flexible emulsion: 52.5g, anti-flash rust agent: 0.9 to the mixed liquid whose fineness reaches the standard under the stirring condition of 500-600r / m g, Thickener: 0.75g, adjust the viscosity of the coating to 800±200mP·s, and obtain component A of the water-based silicone anti-cracking and anti-corrosion coating after filtration.

[0081] Wherein: the preparation method of organosilicon flexible emulsion is:

[0082] The preparation of silicone flex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com