A kind of instant magnesium alloy and preparation method thereof

A magnesium alloy, instant technology, applied in the field of metal materials, can solve the problem of low corrosion rate, and achieve the effect of improving construction efficiency, high mechanical strength and good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: Mg-3.5Cu-0.5Ni-1RE alloy

[0023] Weigh the required alloy raw materials in proportion, polish the alloy surface and clean and dry it. Add the alloys one by one into the crucible to melt, keep the temperature at 750°C for 10 minutes and then cool down to 710°C for casting. The casting mold is a water-cooled copper mold. Subsequently, the ingot was subjected to homogenization treatment, and the holding temperature was 500° C. for 15 hours. The homogenized ingot was processed into a cylinder for extrusion processing, the extrusion temperature was 450° C., the extrusion speed was 0.4 mm / s, and the extrusion ratio was 16. After extrusion, the rods are subjected to aging treatment at a temperature of 200°C for 12 hours.

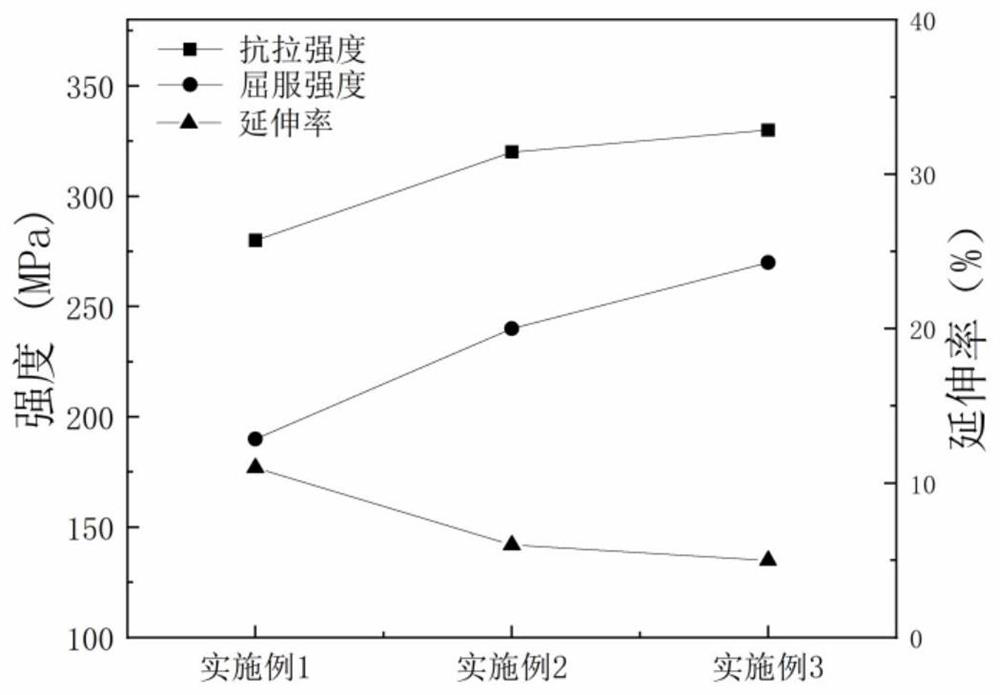

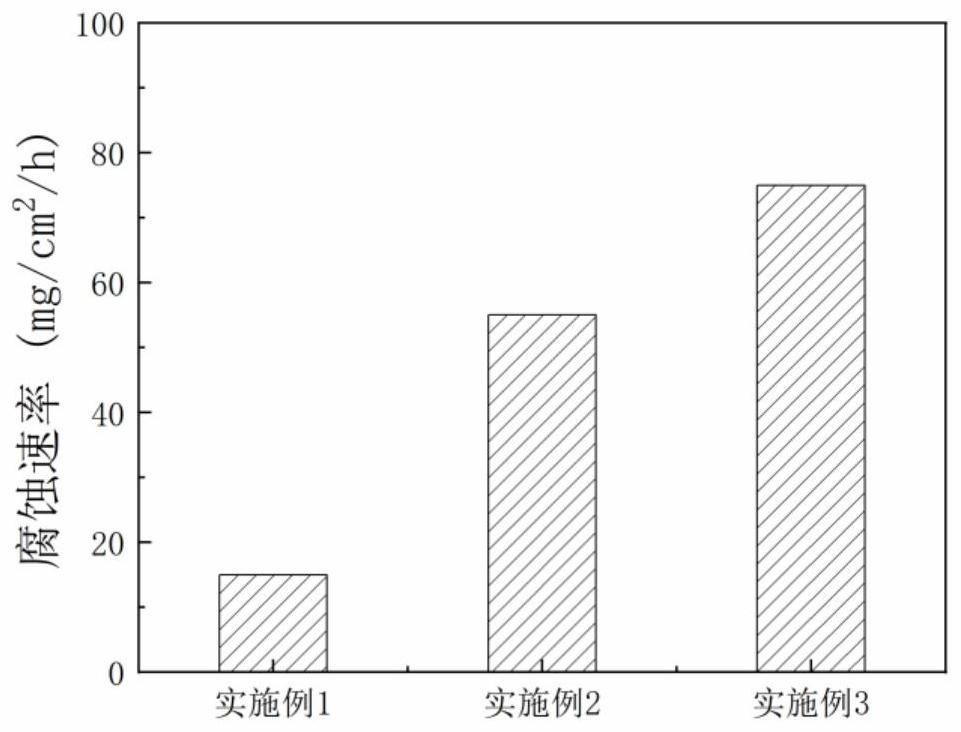

[0024] The room temperature tensile strength of the Mg-3.5Cu-0.5Ni-1RE alloy obtained by the above steps is 280MPa, the yield strength is 190MPa, the elongation is as high as 11%, and the corrosion rate in 0.05% KCl solution is about 15mg / ...

Embodiment 2

[0025] Embodiment 2: Mg-3.5Cu-3Ni-1.5RE alloy

[0026] Weigh the required alloy raw materials in proportion, polish the alloy surface and clean and dry it. Add the alloys one by one into the crucible to melt, keep the temperature at 750°C for 10 minutes and then cool down to 730°C for casting. The casting mold is a water-cooled copper mold. Subsequently, the ingot was subjected to homogenization treatment, and the holding temperature was 500° C. for 15 hours. The homogenized ingot was processed into a cylinder for extrusion processing, the extrusion temperature was 450° C., the extrusion speed was 0.4 mm / s, and the extrusion ratio was 16. After extrusion, the rods are subjected to aging treatment at a temperature of 220°C for 15 hours.

[0027] The room temperature tensile strength of the Mg-3.5Cu-3Ni-1.5RE alloy obtained through the above steps is 320MPa, the yield strength is 240MPa, the elongation is 6%, and the corrosion rate in 0.05% KCl solution is about 55mg / cm 2 / ...

Embodiment 3

[0028] Embodiment 3: Mg-4.5Cu-3.5Ni-3.5RE alloy

[0029] Weigh the required alloy raw materials in proportion, polish the alloy surface and clean and dry it. Add the alloys one by one into the crucible to melt, keep the temperature at 760°C for 10 minutes and then cool down to 730°C for casting. The casting mold is a water-cooled copper mold. Subsequently, the ingot was subjected to homogenization treatment, and the holding temperature was 520° C. for 15 hours. The homogenized ingot was processed into a cylinder for extrusion processing, the extrusion temperature was 450° C., the extrusion speed was 0.4 mm / s, and the extrusion ratio was 16. After extrusion, the rods are subjected to aging treatment at a temperature of 225°C for 15 hours.

[0030] The room temperature tensile strength of the Mg-4.5Cu-3.5Ni-3.5RE alloy obtained by the above steps is 330 MPa, the yield strength is 270 MPa, the elongation is 5%, and the corrosion rate in 0.05% KCl solution at 40 ° C is about 75 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com