High-performance scissors-fork type aerial work platform hydraulic system

A kind of aerial work platform and hydraulic system technology, which is applied in the direction of fluid pressure actuation system components, fluid pressure actuation device, lifting device, etc., can solve the problems such as large impact of vehicle parking, frustrating turning, and inability to release brakes, etc., to achieve The effect of improving vehicle parking shock, improving climbing ability, and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

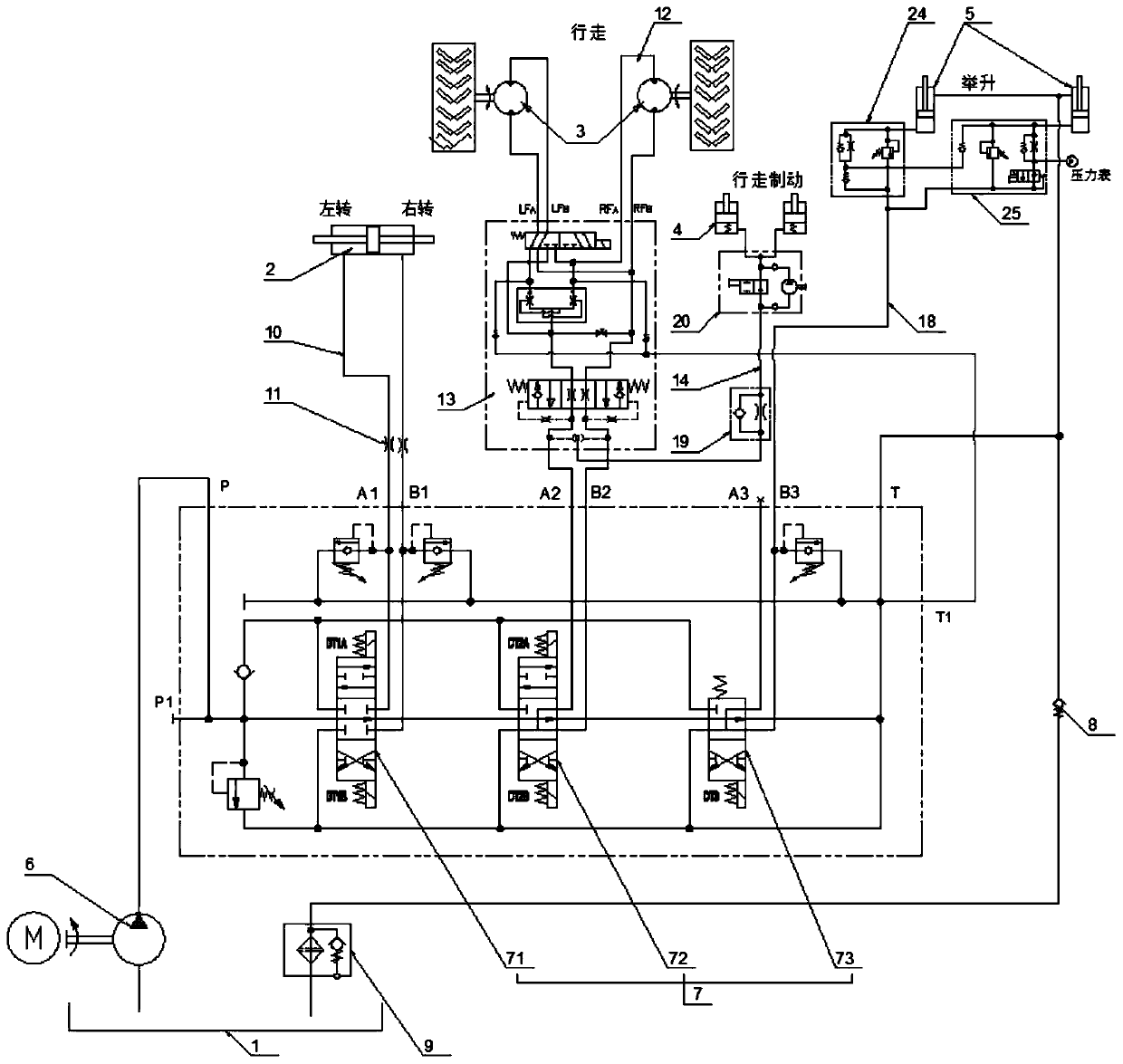

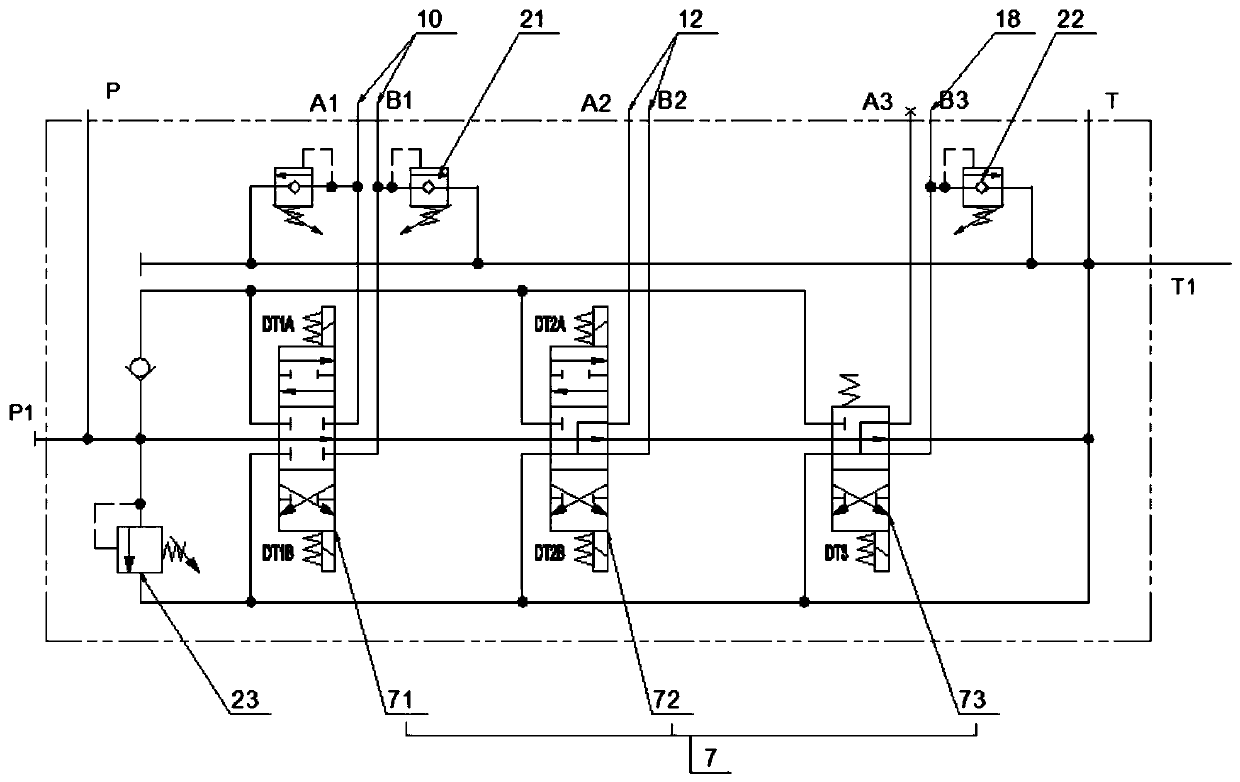

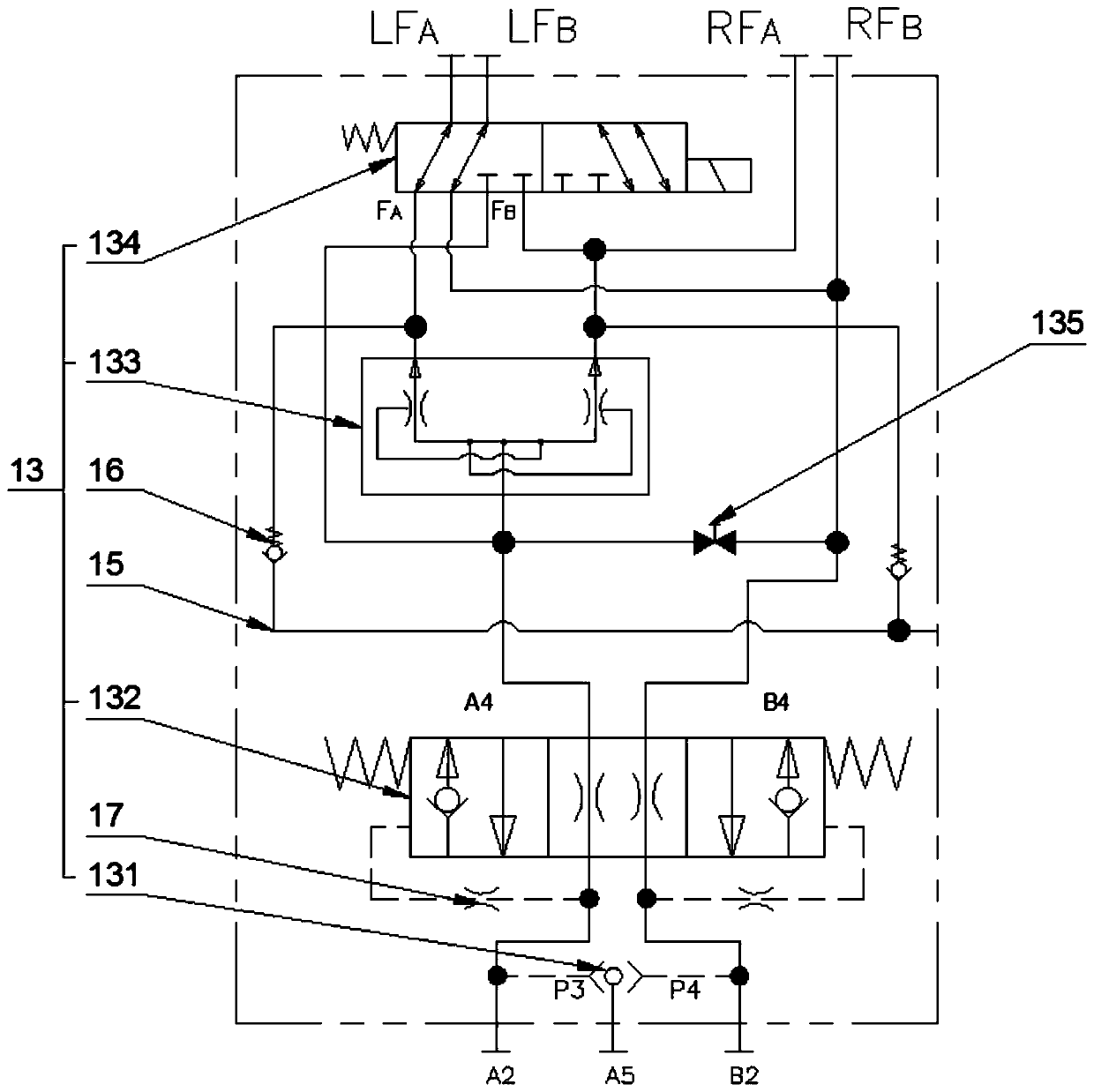

[0028] See attached figure 1 And attached figure 2 , a high-performance scissor-type aerial work platform hydraulic system, including a fuel tank 1, a steering cylinder 2, a traveling motor 3, a traveling brake 4 and a lifting cylinder 5, the fuel tank 1 is connected to a hydraulic pump 6, and the steering cylinder 2 It is used to drive the steering of the work platform, the travel motor 3 is used to drive the work platform to walk, and the lifting cylinder 5 is used to drive the scissors of the work platform to lift mechanically, wherein the hydraulic pump 6 is connected with a triple electromagnetic reversing valve 7. The triple electromagnetic reversing valve 7 has an oil inlet P and an oil return port T, and includes a connected first solenoid valve 71, a second solenoid valve 72 and a third solenoid valve 73, and the oil inlet P It c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com