Internal series type battery cell and internal series type battery

A technology of internal series connection and battery cells, applied in the direction of non-aqueous electrolyte batteries, secondary batteries, lithium batteries, etc., can solve problems such as complex structures, achieve uniform contact, reduce overall internal resistance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

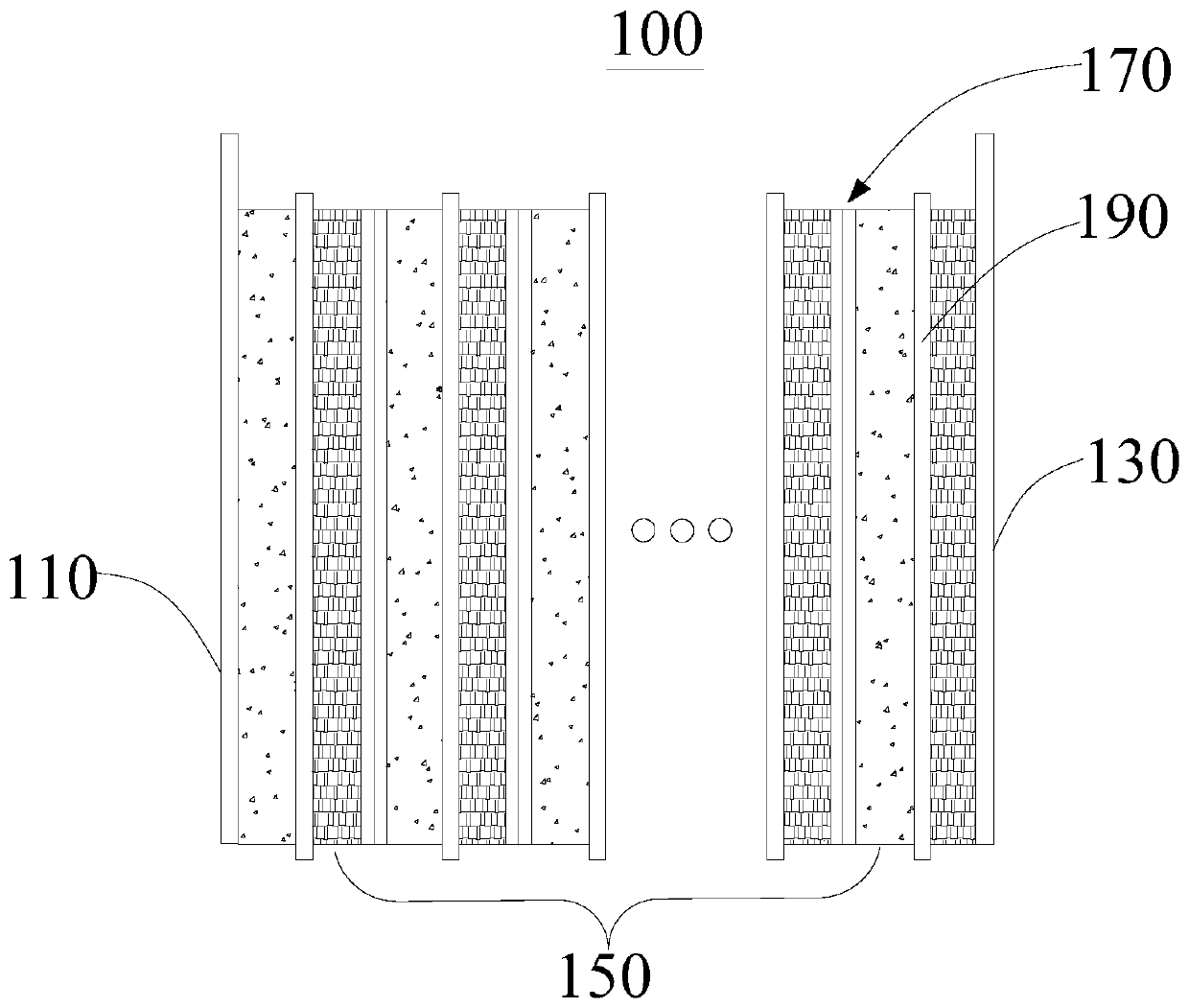

[0033] see in conjunction Figure 1 to Figure 4 , the present embodiment provides an internal series battery cell 100, which has high output voltage, low internal resistance, simple structure, and low process implementation difficulty.

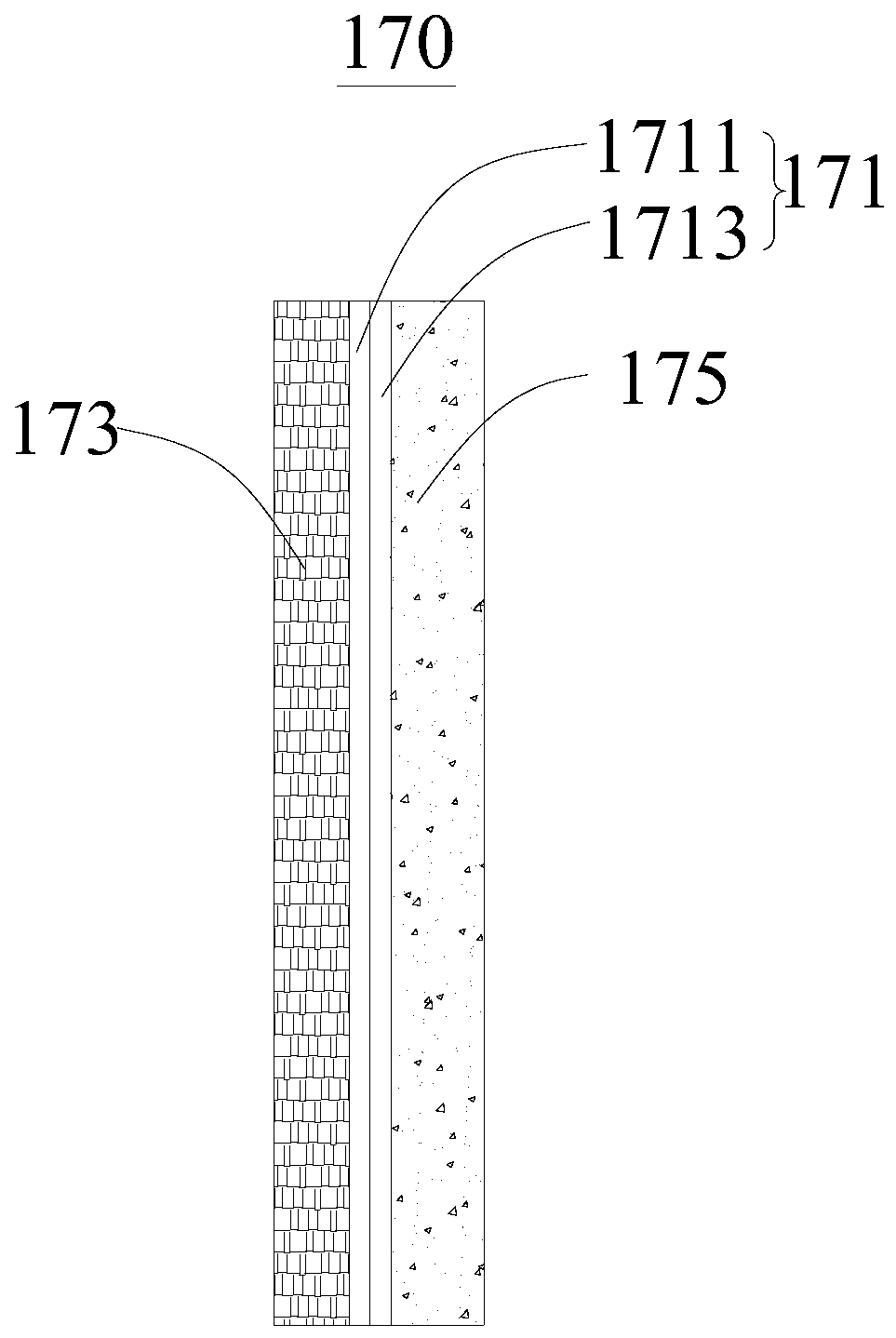

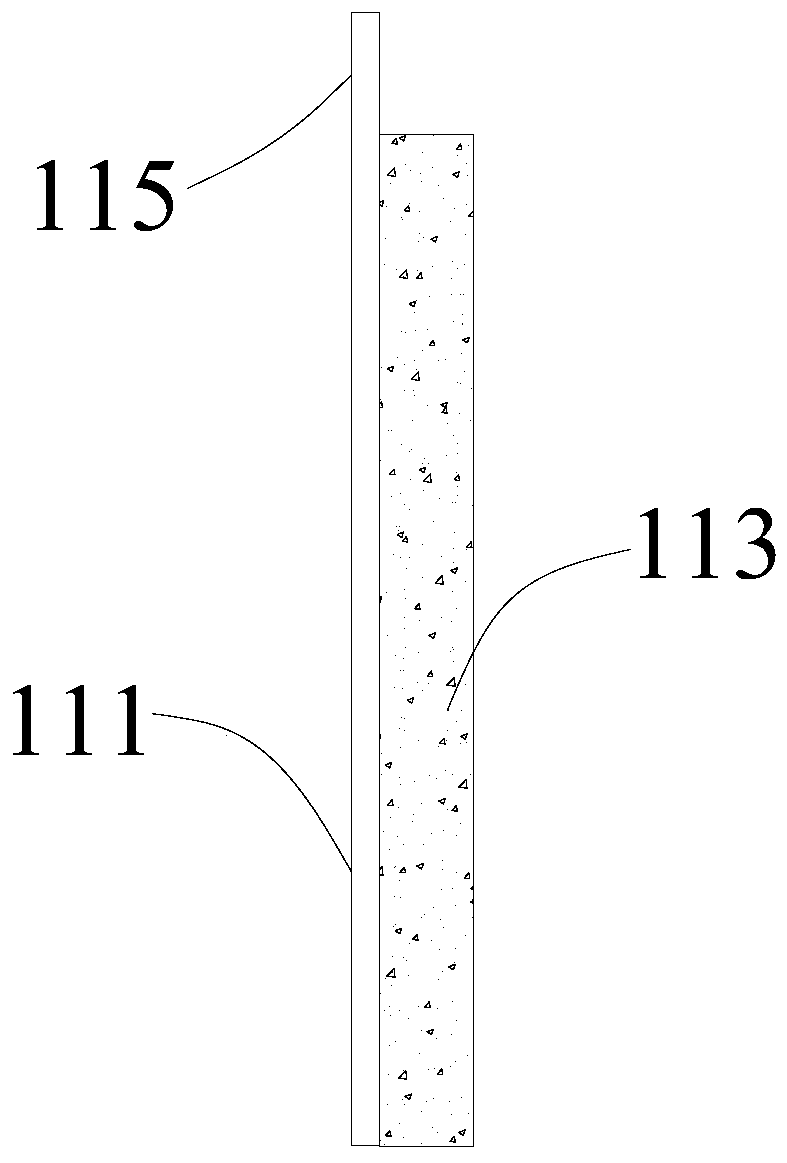

[0034] The internal series battery cell 100 provided in this embodiment includes an outer layer negative pole piece 110, an outer layer positive pole piece 130, and a battery cell series group 150. The component 110 is connected to the negative terminal, and the outer layer positive component 130 is connected to the positive terminal. The cell series group 150 includes a plurality of overlapping internal cell pole pieces 170, and a useful The internal diaphragm 190 blocks the passage of electrons, and every two adjacent internal cell pole pieces 170 form a power supply unit, and multiple power supply units are connected in series.

[0035] In this embodiment, the battery cell series group 150 is accommodated in the battery case, and the surro...

no. 2 example

[0057] This embodiment provides an internal series battery, including a casing and an internal series battery cell 100. Here, the basic structure, principle and technical effect of the internal series battery cell 100 are the same as those in the first embodiment. For the description, for parts not mentioned in this embodiment, reference may be made to the corresponding content in the first embodiment.

[0058] The internal series battery cell 100 includes an outer layer negative pole piece 110, an outer layer positive pole piece 130, and a battery cell series group 150. The two ends of the battery cell series group 150 have a positive terminal and a negative terminal respectively, and the outer layer negative pole piece 110 is connected to the negative terminal. , the outer positive pole member 130 is connected to the positive end, the battery cell series group 150 includes a plurality of overlapping internal battery pole pieces 170, and an inner wall for blocking the passage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com