Pre-bare cell top sealing tab bending debugging device and working flow thereof

A bare cell and tab technology, which is applied in the field of debugging devices for tabs before top sealing of bare cells, can solve problems such as dislocation of top seal, deviation of tab bending height and measurement error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

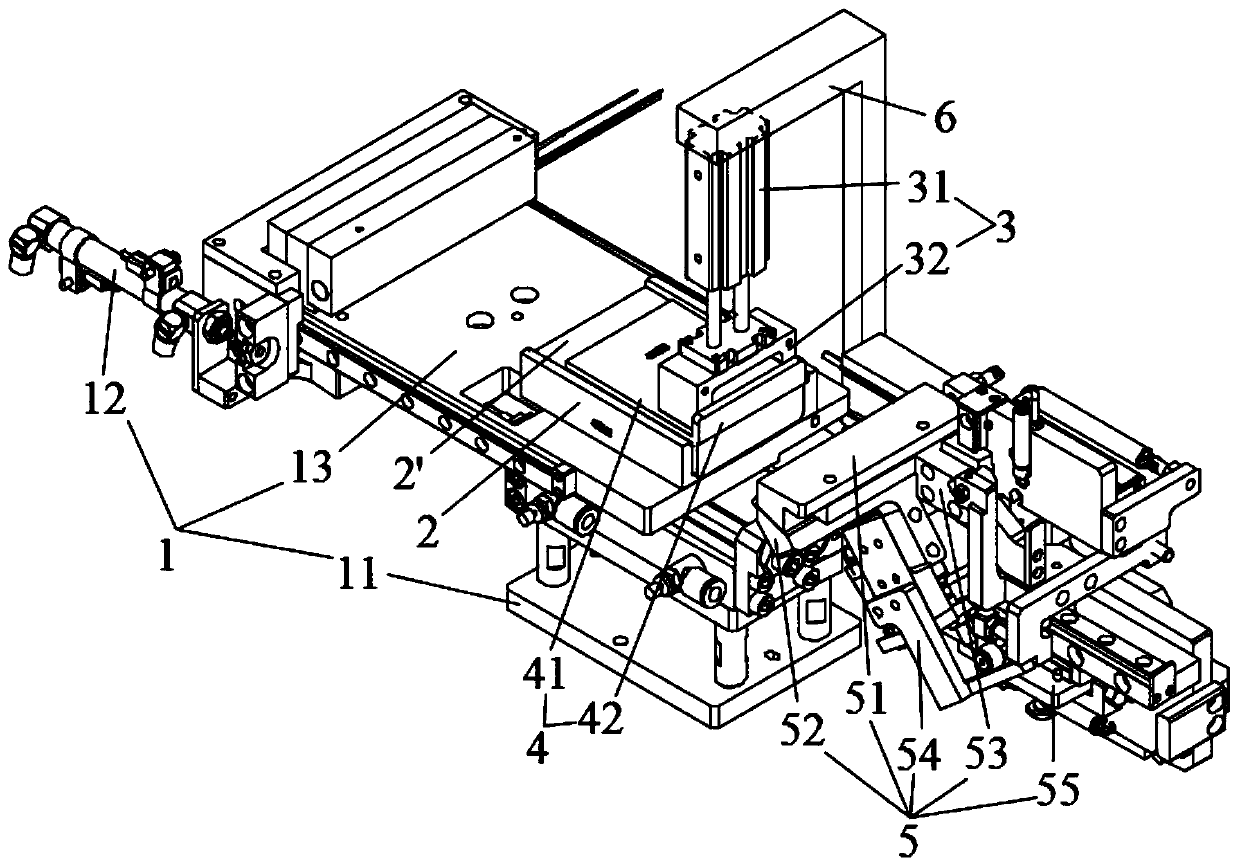

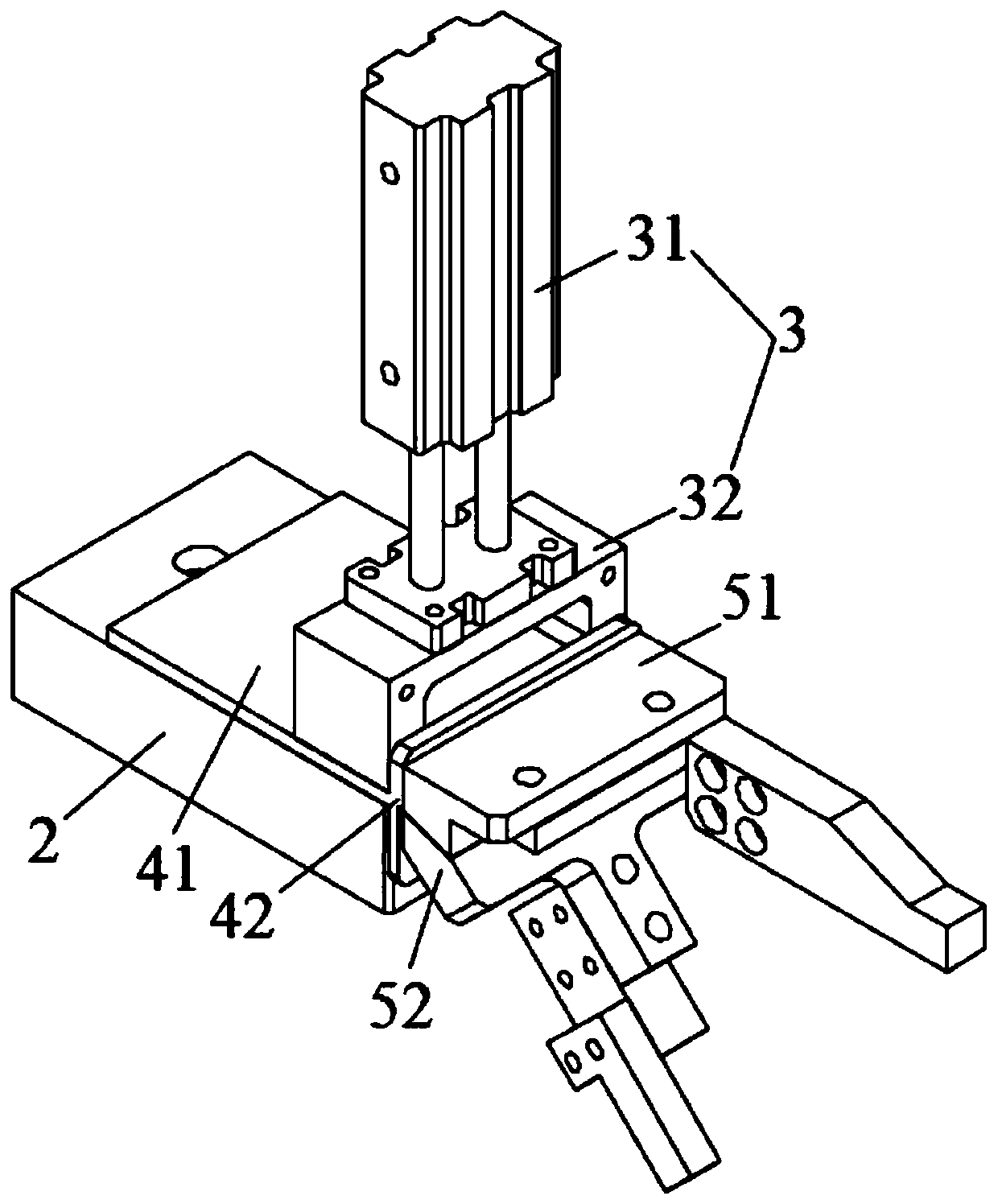

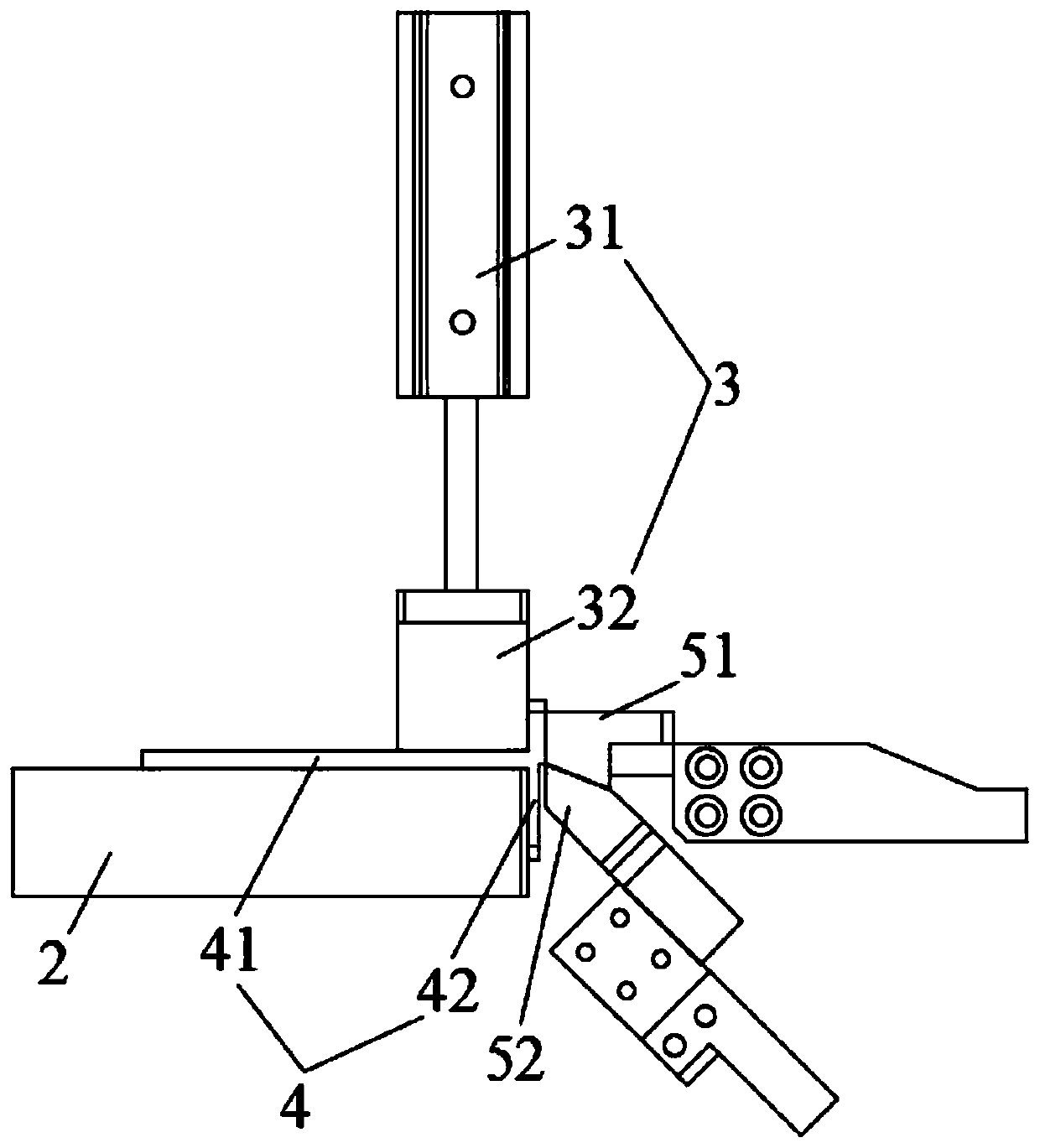

[0035] Such as Figure 1-5 As shown, a debugging device for folding tabs before top-sealing bare cells includes a mobile platform 1, a workbench 2, a pressing device 3, a debugging block 4, and a tab folding device 5. The workbench 2 is set on the mobile platform 1. The workbench 2 is provided with a groove 2 ′, a debugging block 4 is arranged in the groove 2 ′, a pressing device 3 is arranged on the mobile platform 1 through a bracket 6, and the pressing device 3 and the folding tab device 5 all correspond to the debugging block 4. During work, first place the debugging block 4 in the groove 2', and the groove 2'will adsorb and lock the debugging block 4; then the moving platform 1 drives the debugging block 4 on the workbench 2 to move forward to the specified position; Then the pressing device 3 starts to work to compress and fix the debugging block 4; finally the folding tab device 5 starts to work and moves to the debugging block 4 until it contacts the debugging block 4; ...

Embodiment 2

[0046] Such as Figure 1-5 As shown, a working process of the debugging device for folding the tabs before the top sealing of the bare cell according to the first embodiment includes the following steps:

[0047] S1. Place the debugging block 4 in the groove 2', and the groove 2'will adsorb and lock the debugging block 4; the bottom of the groove 2'is provided with multiple air holes, which are connected to the air pump through the air pipe; this structural design It is beneficial to adsorb and fix the debugging block 4 in the groove 2';

[0048] S2. The mobile platform 1 drives the debugging block 4 on the workbench 2 to move forward to the designated position; the platform 13 and the frame 11 are connected by sliding rails; during work, the first telescopic device 12 starts to work, pushing the platform 13 to Before moving, the platform 13 is pushed to the designated position, and the workbench 2 fixed on the platform 13 is also pushed to the designated position;

[0049] S3. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com