Vibration exciter bearing flexible assembly tool and assembly method thereof

A flexible assembly and vibration exciter technology, applied in the manufacture of tools, hand-held tools, etc., to achieve the effect of preventing damage to bearings and shafts, simple structure, and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

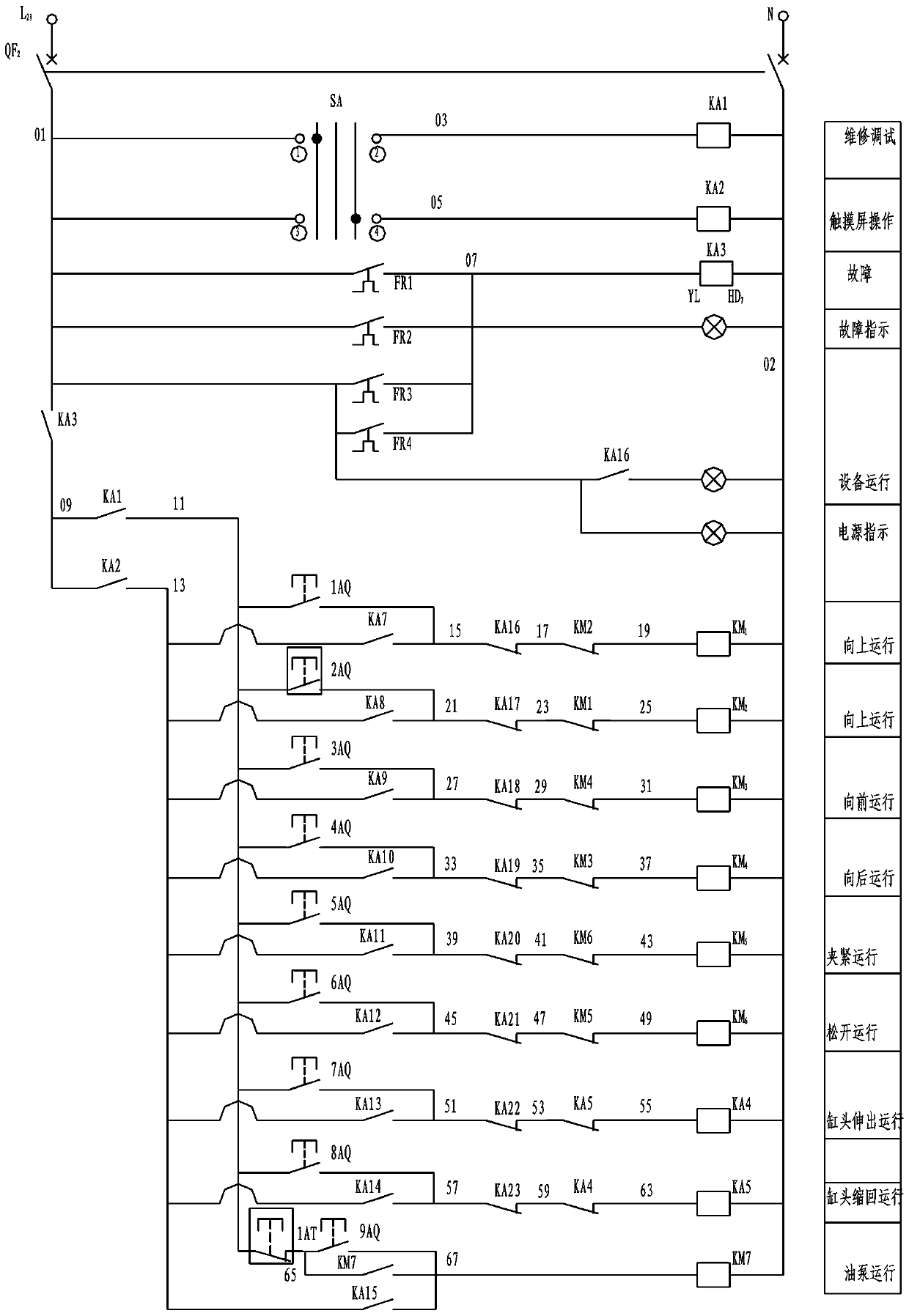

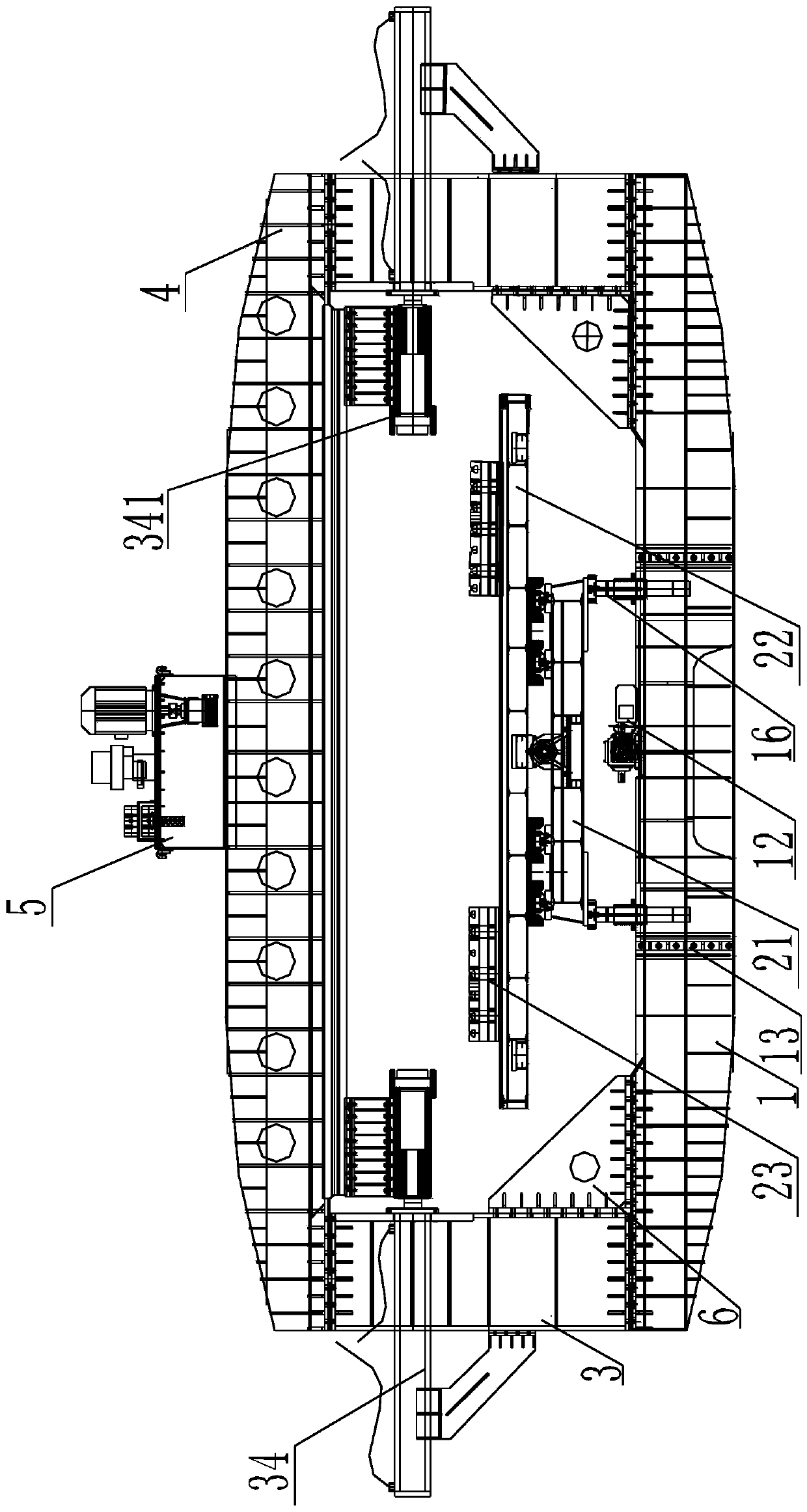

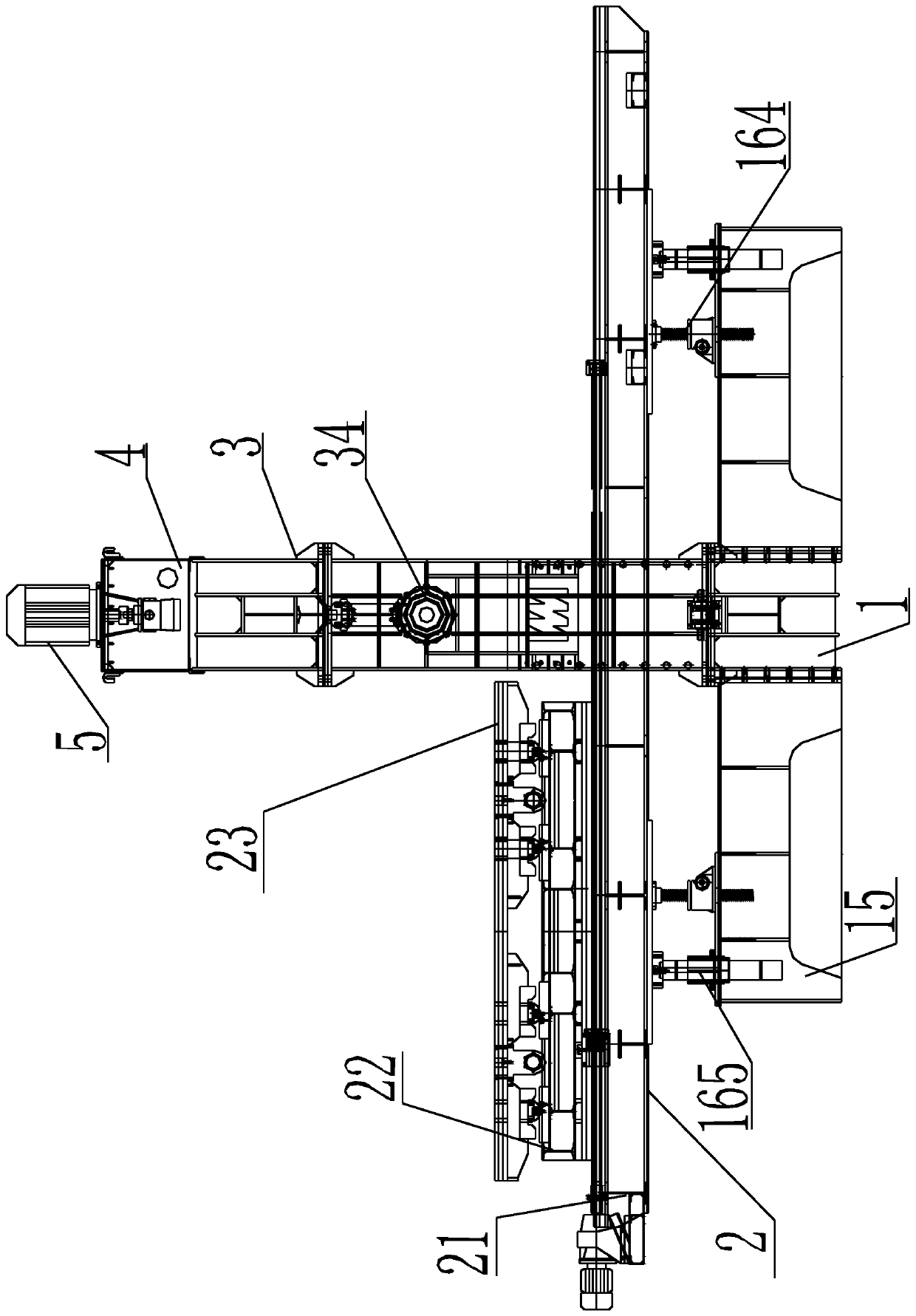

[0038] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings, in which the same reference numerals represent the same components. In order to keep the drawings concise, each drawing only schematically shows the parts related to the invention, and they do not represent the actual structure of the product.

[0039] Such as Figure 1-14As shown, the present invention is a flexible assembly tool for a vibrator bearing and an assembly method for the tool, wherein the flexible assembly tool includes an intermediate beam for supporting and fixing the vibrator clamping unit 2 and the hydraulic cylinder support frame 3 Unit 1, the middle part of the middle beam unit 1 is provided with a vibrator clamping unit 2 for clamping the vibrator and adjusting the position of the vibrator, and the tops of both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com