High-strength environmentally-friendly automobile grille decorative strip

A high-strength, decorative strip technology, applied in the field of auto parts, can solve the problems of broken, poor anti-collision performance, poor anti-collision performance, etc., and achieve the goal of enhancing anti-collision ability, enhancing anti-collision strength and reducing rigid force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

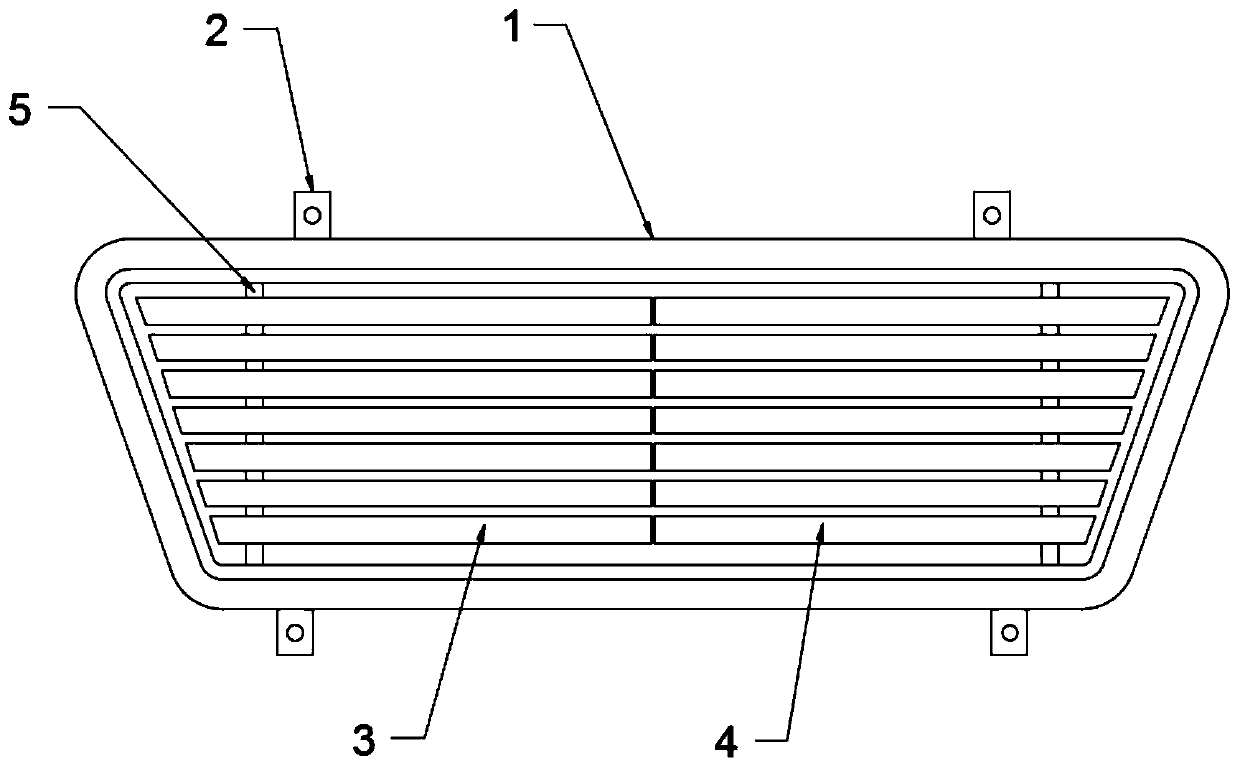

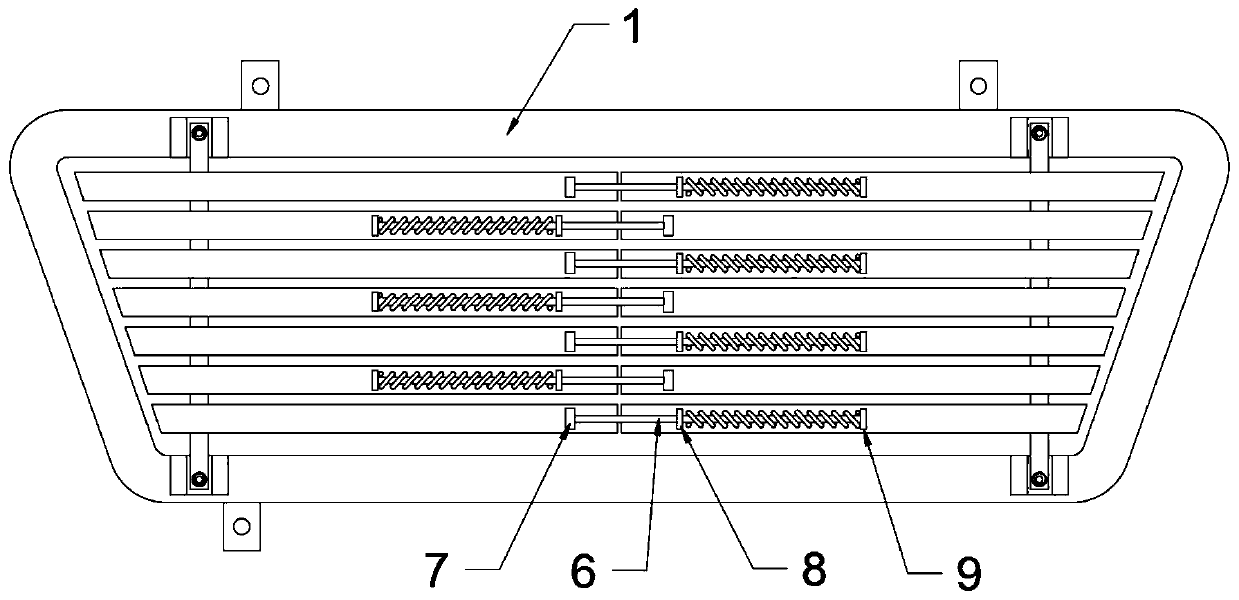

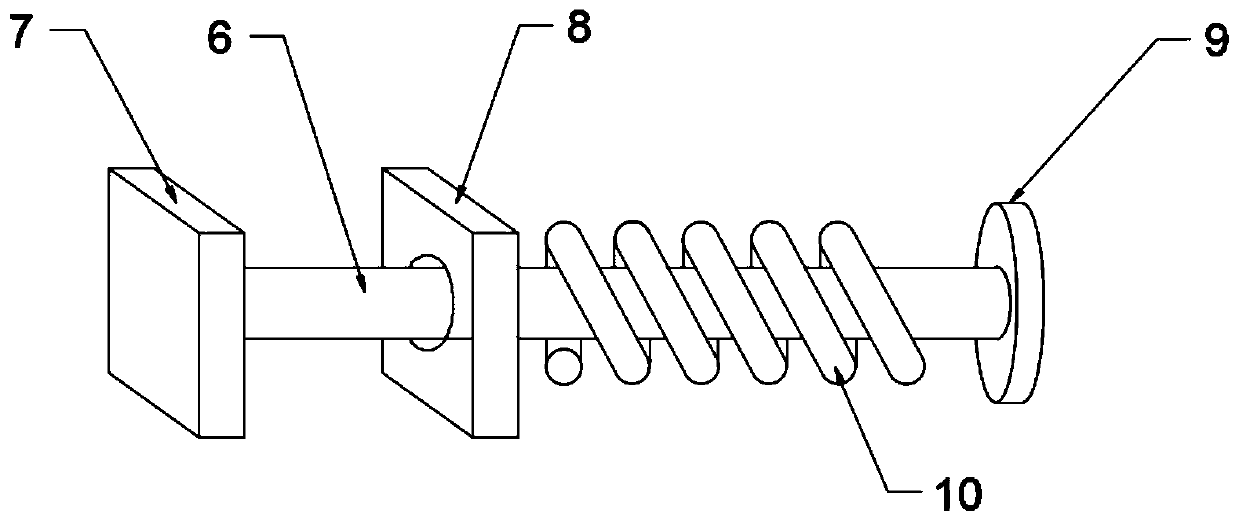

[0022] see Figure 1-5 , in the embodiment of the present invention, a high-strength environment-friendly automobile grille trim includes an installation frame 1; the installation frame 1 is fixedly connected to the steel frame of the front of the vehicle through the installation plate 2 distributed on its outer edge, which is convenient for installation and ensures The stability of the installation; the installation frame 1 is nested with multiple groups of decorative strip assemblies distributed up and down, the decorative strip assembly runs through the socket rod 5 and is rotatably connected with the socket rod 5, and the decorative strip assembly includes a symmetrically arranged first The decorative strip 3 and the second decorative strip 4; a horizontal elastic component is arranged between the first decorative strip 3 and the second decorative strip 4, and the horizontal elastic component includes a first fixing plate 7 and a second fixing plate 8 And the limiting plat...

Embodiment 2

[0025] The difference between this embodiment and Embodiment 1 is that the upper and lower ends of the sleeve rod 5 respectively extend into the installation frame 1, and the installation frame 1 is provided with a longitudinal buffer assembly including a sliding groove 11, and the sliding groove 11 is provided with a sliding The guide rod 12 fixedly connected to the inner wall of the groove 11, the guide rod 12 runs through the sleeve rod 5, the sleeve rod 5 is provided with a through hole 13 cooperating with the guide rod 12, the sleeve rod 5 both sides are provided with a second spring 14, the second The second spring 14 is socketed on the guide rod 12. When the decorative strip assembly has a slight frontal collision, the socket rod 5 slides in the sliding groove 11, and the second spring 14 can buffer and absorb the collision to avoid the direct breaking of the decorative strip assembly. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com