Pipeline feeding system for coarse particle coal slurry and feeding method thereof

A feeding system and coarse particle technology, which is used in conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problems of coal slurry clogging, frequent failures, and large variation range of coal slurry concentration at the outlet of the slurry tank. The effect of avoiding cavitation and avoiding precipitation accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

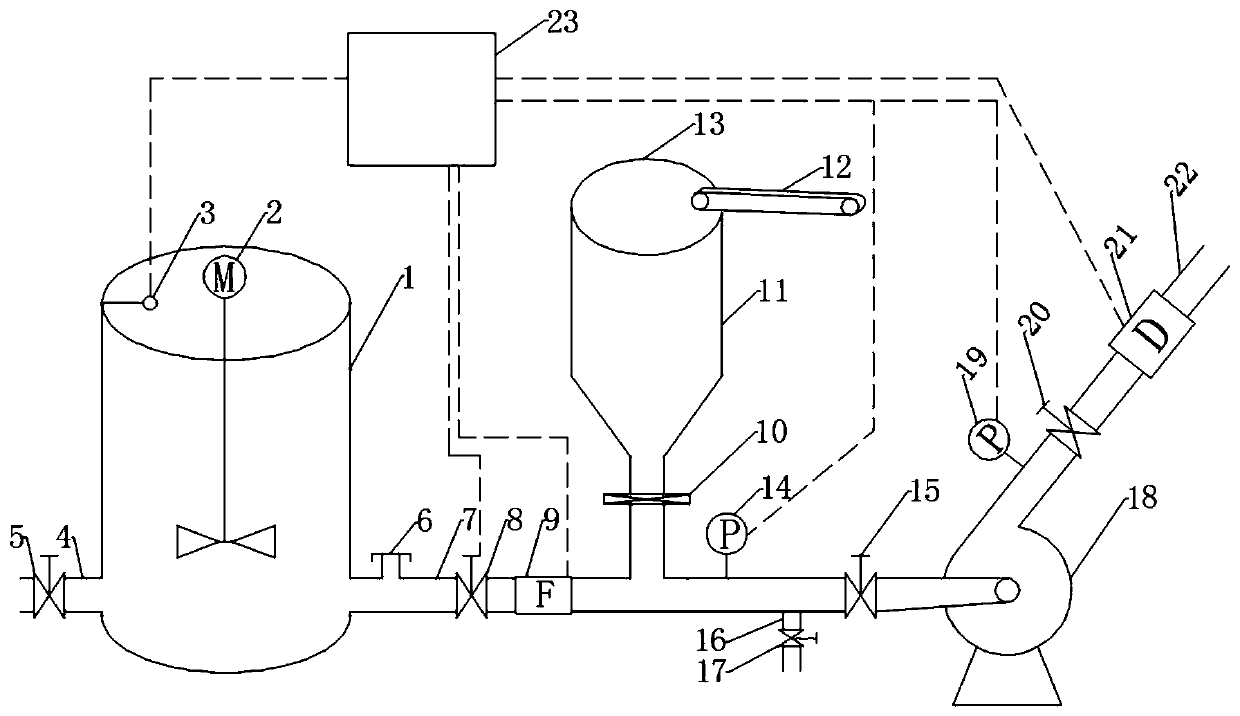

[0021] Please refer to figure 1 , a coarse coal slurry pipeline feeding system, comprising a water tank 1, a coal supply funnel 11, a PLC control system 23, a slurry pump inlet pipe 25 and a slurry pump 18; the lower end of the water tank 1 is provided with a water tank Water inlet pipe 4, water tank outlet pipe 7, the upper end of the water tank 1 is provided with a water tank ultrasonic level gauge 3, the water tank inlet pipe 4 is provided with a water tank inlet valve 5, and the water tank outlet pipe 7 is provided with a water tank Outlet flow regulating valve 8 and water tank outlet electromagnetic flowmeter 9;

[0022] The structure of the coal supply funnel 11 is that the upper part is circular and the lower part is conical (40-60 degrees), which can avoid the deposition and accumulation of coarse coal at the bottom of the funnel, and its outlet is directly connected to the inlet pipe of the slurry pump and connected to the water tank Intercommunication, the upper end...

Embodiment 2

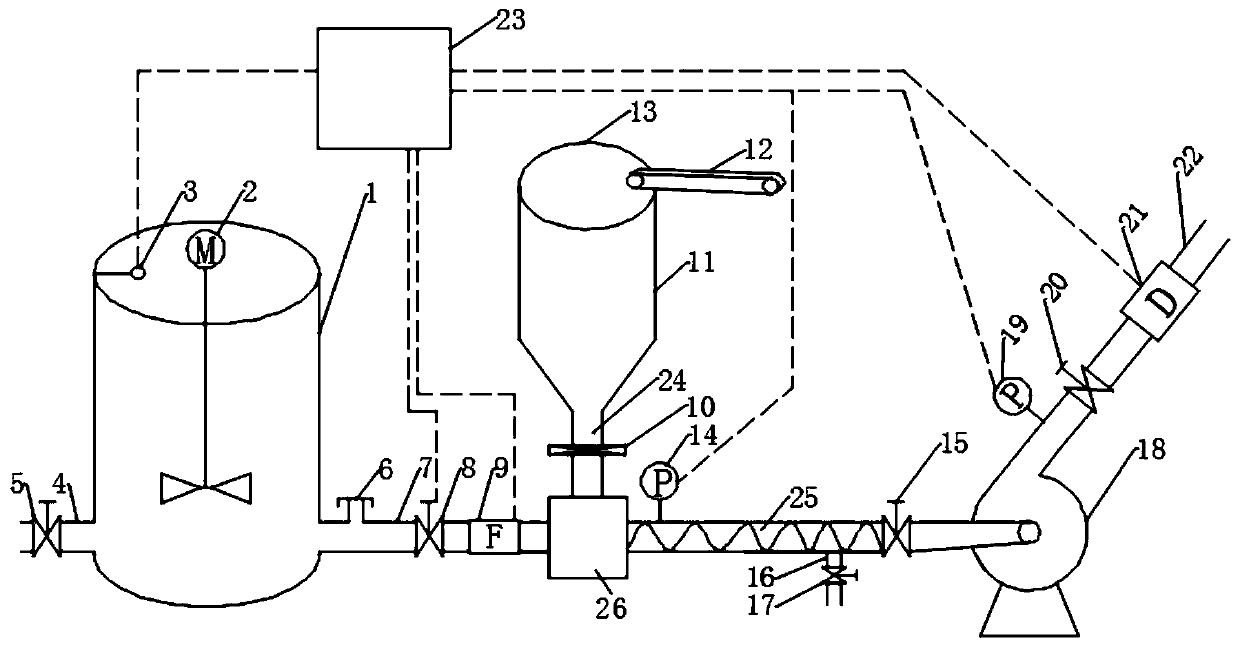

[0027] Please refer to figure 2 , is different from Example 1 in that, in order to improve the uniformity of coal slurry mixing, a mixing and stirring device 26 is provided at the confluence of the coal supply pipe 24 and the water tank outlet pipe 7; Conveyor 27.

[0028] The feeding method of the described coarse coal slurry pipeline feeding system includes a feeding start method and a feeding stop method:

[0029] Described feeding starting method comprises the steps:

[0030] Step 1: Open the water inlet valve of the water tank 1, the water tank 1 can be continuously filled with water, and the water tank outlet flow regulating valve 8 is linked with the water tank outlet flow regulating valve 8 through the water tank ultrasonic level gauge 3, and the water tank outlet flow regulating valve 8 is reached after a certain liquid level automatically open;

[0031] Step 2: Open the flat gate 10 at the bottom of the coal supply funnel so that the coal supply funnel 11 can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com