Turnover and fixed without-vertical-bar-truss aluminum formwork supporting system

A support system and finalized technology, applied in the connection of formwork/formwork/work frame, preparation of building components on site, construction, etc., can solve waste of materials and man-hours, difficulty in installation and disassembly, messy materials on site, etc. problems, to achieve the effect of reducing labor costs, low use costs, and ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and examples, but the present invention is not limited in any way. Any changes or improvements made based on the teaching of the present invention belong to the protection scope of the present invention.

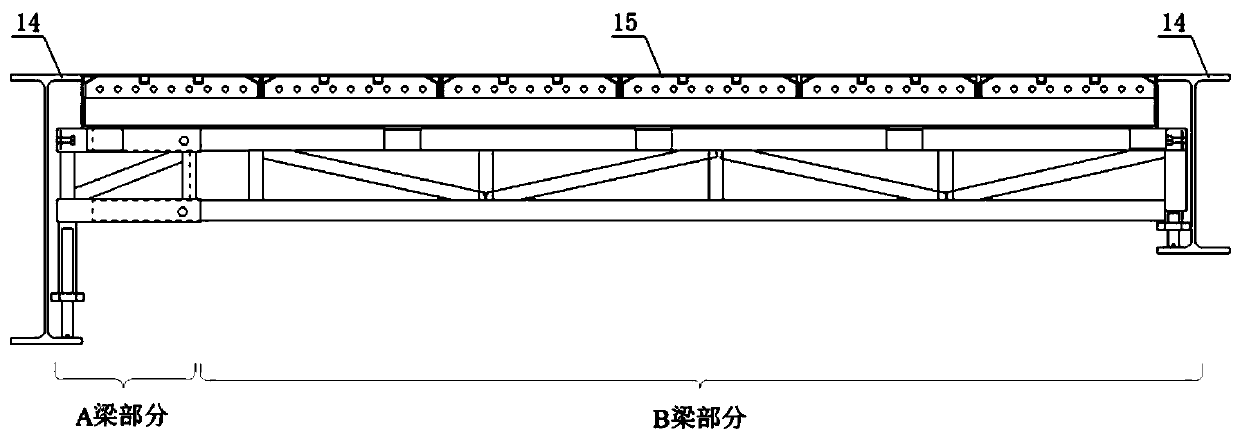

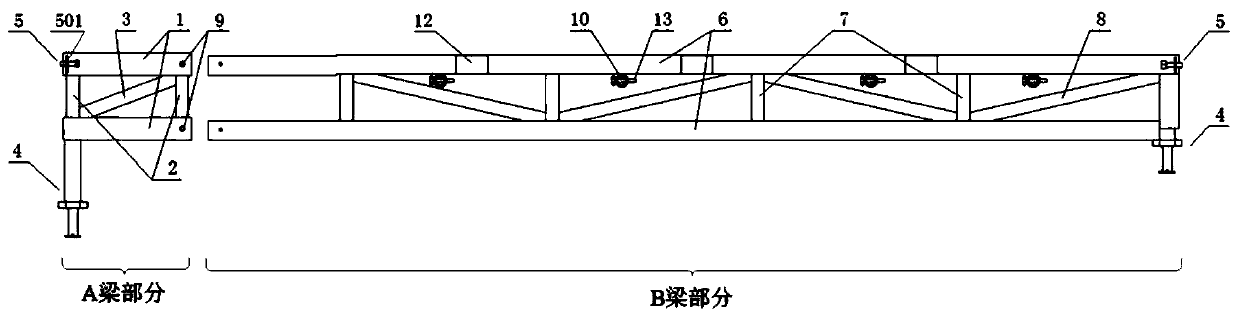

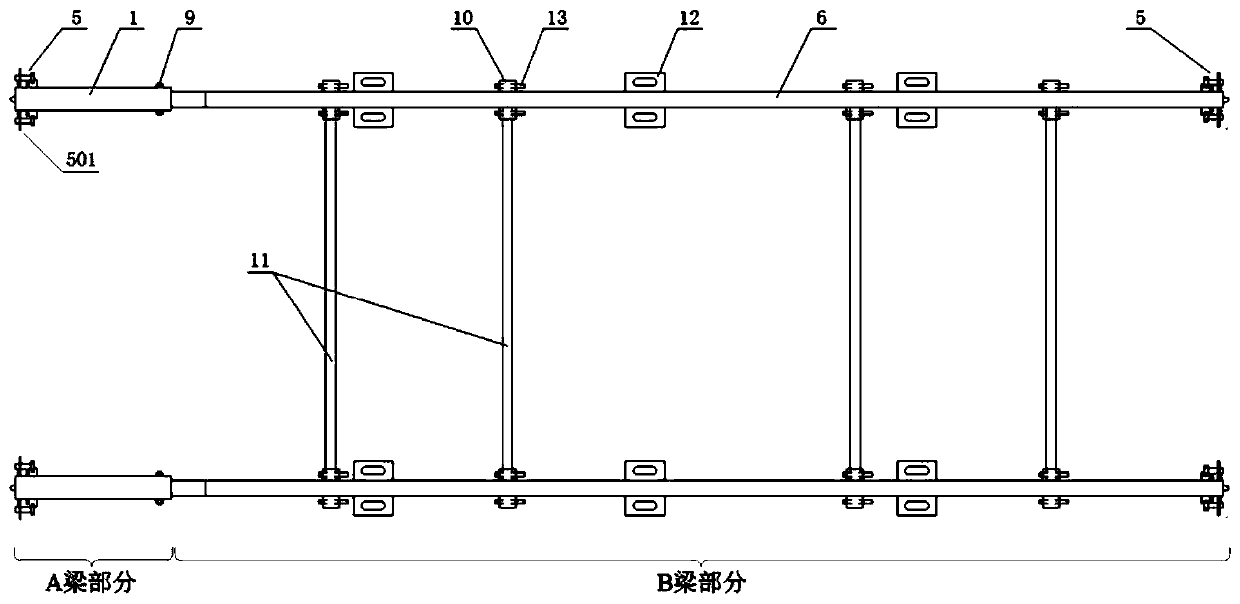

[0019] Such as Figures 1 to 5 As shown, the present invention includes an A beam part and a B beam part. The A beam part includes a main keel I1, a secondary keel I2, an oblique strut I3, an adjustable support base 4, and a detachable connection assembly 5. The main keel I1 Horizontally arranged at intervals up and down and both ends are fixedly connected to the secondary keels I2 arranged vertically at intervals to form a frame structure I. The head and tail ends of the upper and lower adjacent main keels I1 are connected by oblique struts I3, and the adjustable support base 4 is connected to the frame structure. At the bottom of one end of the structure I, the detach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com