Deformation sensor and device for measuring load of vehicle hub, and automobile

A deformation sensor, wheel hub technology, applied in the direction of measuring device, wheel hub, measuring force, etc., can solve the problems of acquiring vehicle load, unable to anytime, anywhere, weighbridge cost and construction cost, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

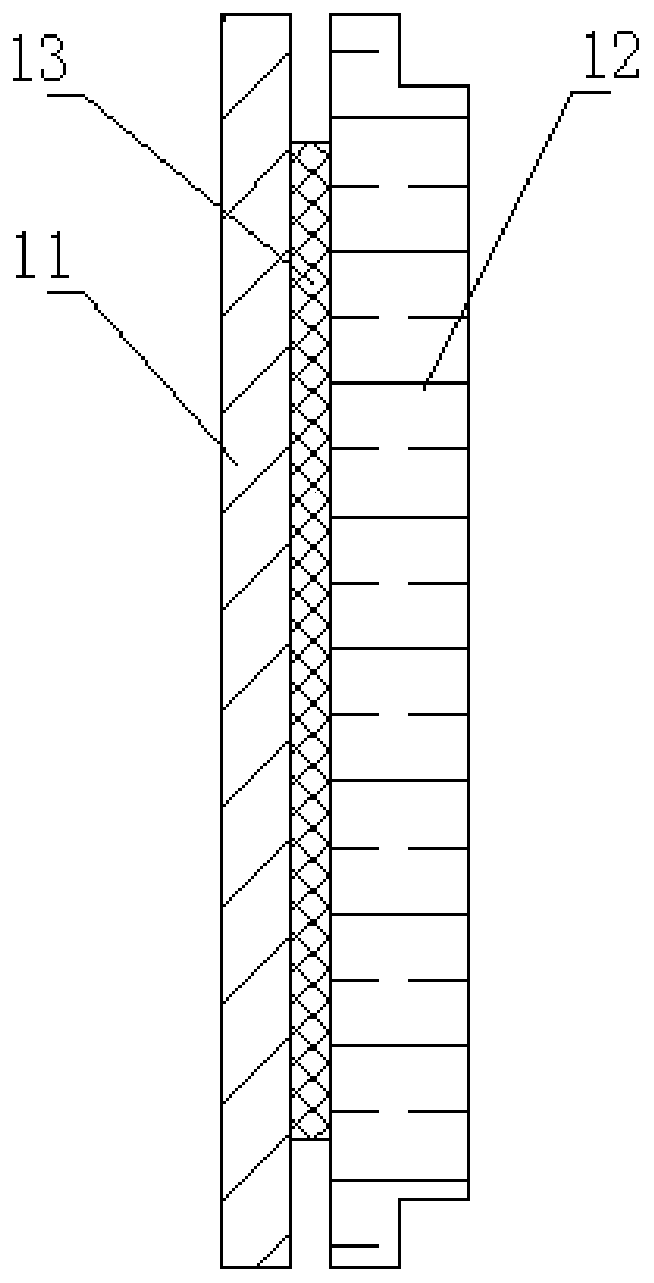

[0029] This embodiment provides a deformation sensor for measuring vehicle hub load, such as figure 1 As shown, the deformation sensor includes a metal lining 11 and a resistance strain gauge 12 , and the resistance strain gauge 12 is fixed on the metal lining 11 . Specifically, the strain gauge 12 is fixed on the metal lining 11 by structural glue 13 . In use, the metal lining 11 is fixed to the hub surface.

[0030] The principle of the embodiment of the present invention is that: when the vehicle hub is loaded, there will be a slight deformation, and this deformation has a certain correspondence with the load of the hub, so the vehicle can be calculated by detecting the tiny deformation of the hub. The load on the hub, that is, the load on the vehicle. The deformation sensor of this embodiment can be used to detect the slight deformation of the hub, that is, the deformation of the hub will drive the deformation of the metal lining 11, and the deformation of the metal lini...

Embodiment 2

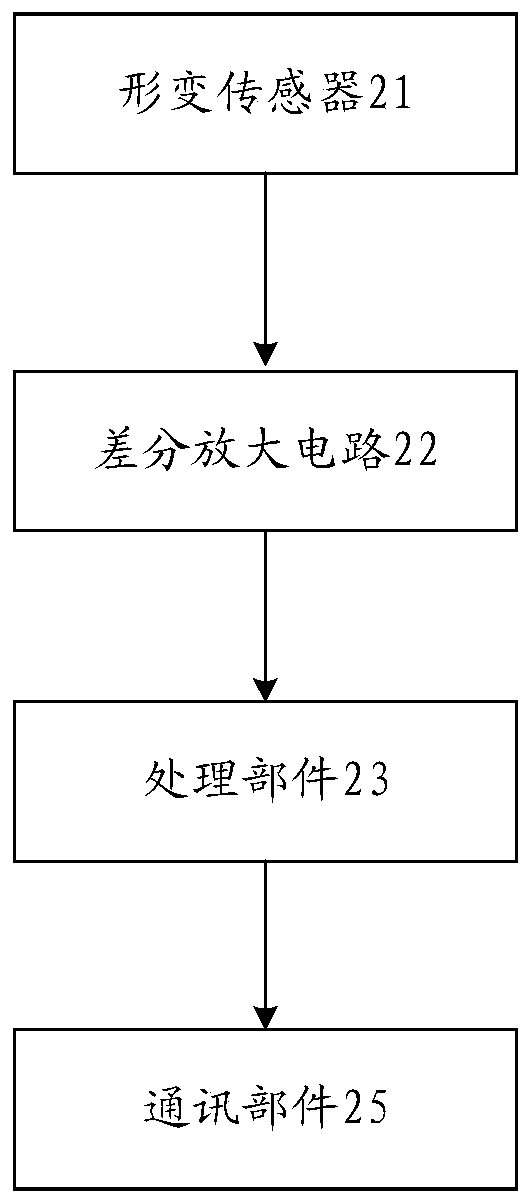

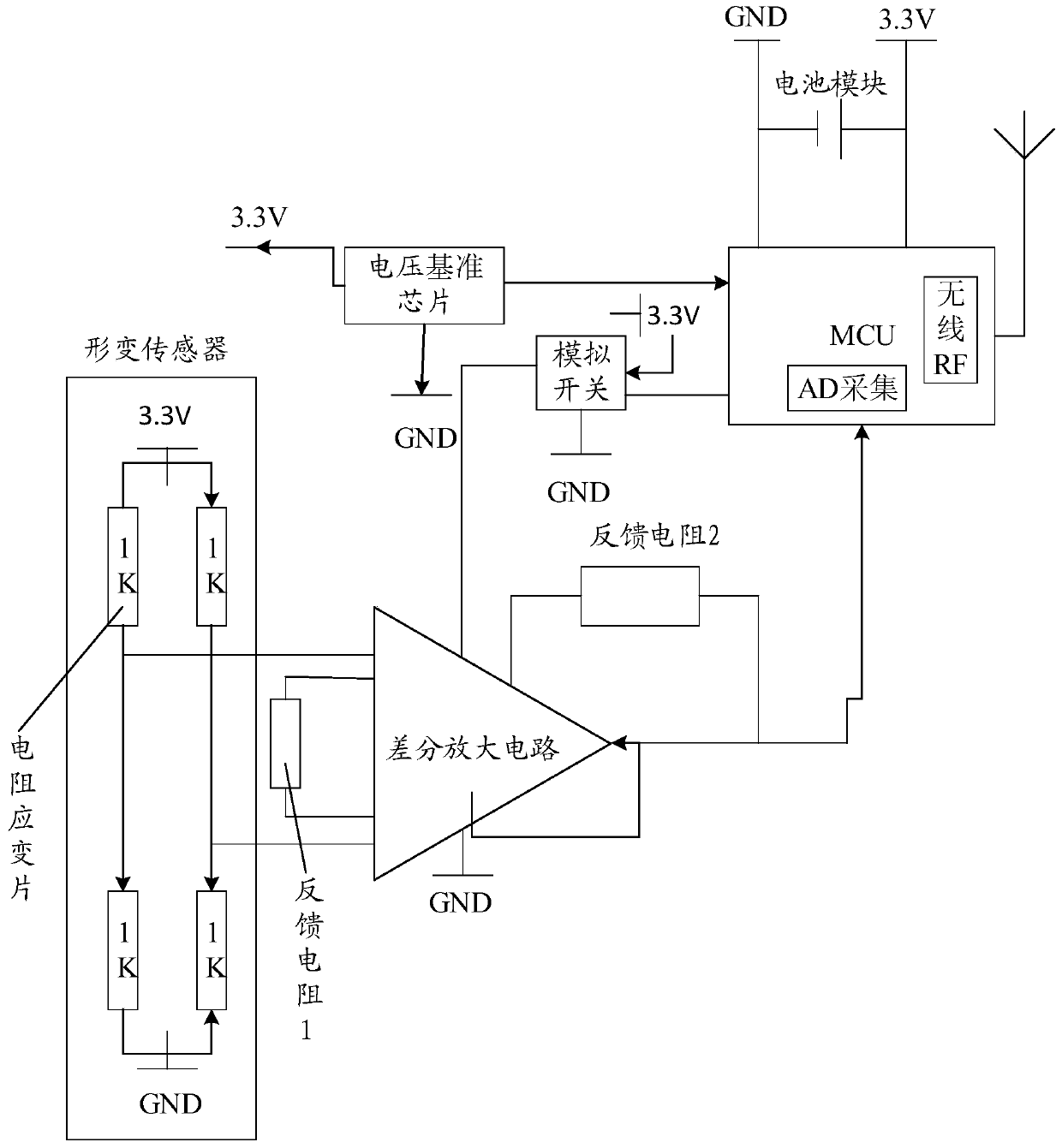

[0036] This embodiment provides a device for measuring the load on the hub of a vehicle, such as figure 2 As shown, the device includes a deformation sensor 21, a differential amplifier circuit 22 and a processing unit 23; the input terminal of the differential amplifier circuit 22 is connected to the deformation sensor 21, and the output terminal of the differential amplifier circuit 22 is connected to the processing unit twenty three. The deformation sensor 21 may be the deformation sensor 21 described in the first embodiment.

[0037] In the present embodiment, the processing unit 23 is a micro control unit (MCU, Microcontroller Unit), and the MCU is also called a single chip microcomputer (Single Chip Microcomputer) or a single chip microcomputer, which is a central processing unit (CPU, Central Process Unit,) The frequency and specifications are appropriately reduced, and the memory (memory), counter (Timer), Universal Serial Bus (USB, Universal Serial Bus), analog / digi...

Embodiment 3

[0068] This embodiment provides a wheel assembly of a vehicle, the wheel assembly includes a device for measuring the load of the vehicle hub, a wheel hub and a tire; the deformation sensor in the device is installed on the outer circumferential surface of the rim of the hub, and the tire It is installed on the hub and covers the deformation sensor. The device for measuring the wheel hub load of the vehicle may be the device for measuring the wheel hub load of the vehicle described in the second embodiment.

[0069] Here, for the convenience of detection, the deformation sensor is installed on the hub, while other components in the device for measuring the load of the vehicle hub can be installed on the hub, or can be installed on other parts of the vehicle independently of the hub.

[0070] Further, the wheel assembly here may only include a part of the device for measuring the load on the hub of the vehicle. Because data transmission can be done wirelessly or through non-ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com