A New Method of Aircraft Engine Calibration

An aircraft engine, a new method of technology, applied in engine testing, jet engine testing, gas turbine engine testing and other directions, can solve the problems of high-speed development, long time period, and many tooling equipment that restrict the company's production progress, saving manpower Cost, commissioning cycle savings, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

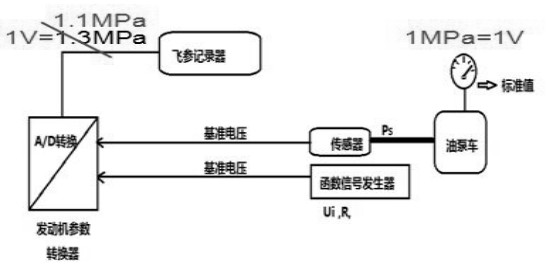

[0022] A new method for aircraft engine calibration, such as figure 2 As shown in , the working range of the engine parameters calibrated in the history is counted, and the central curve of the working range is fitted to serve as the standard model value curve of the same type of aircraft, which is directly written into the engine parameter converter by using the engine parameter ground detection equipment.

[0023] The invention directly writes the standard model value curve into the engine parameter converter through the engine parameter ground detection equipment, replaces the traditional engine parameter calibration method, saves labor costs, improves work efficiency, and has better practicability.

Embodiment 2

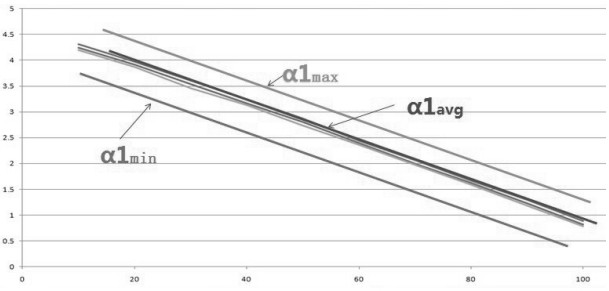

[0025] This embodiment is optimized on the basis of embodiment 1, such as figure 2 As shown in , the historical engine parameter calibration data is counted, and the mean curve of the engine parameter calibration data is counted as the central curve of the working range.

[0026] The maximum and minimum values under each scale of the historical data are counted, and all the maximum and minimum values under each scale are fitted to obtain a smooth straight line, and the interval between the fitted curves is the working interval.

[0027] Calculate the mean value under each scale of the historical data, and fit the mean value under each scale to obtain the central curve of the working interval.

[0028] This invention completely subverts the low-efficiency and high-cost working mode that requires 5 people to use 8 sets of tooling equipment and operate for 2 hours. It is transformed into only 1 person using 1 piece of equipment, and the writing of all engine parameter calibr...

Embodiment 3

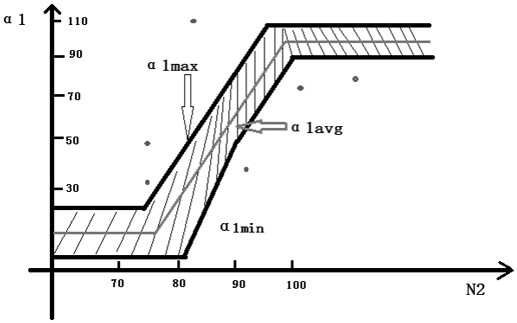

[0031] A new method of aircraft engine calibration is based on the principle of statistics, statistics, arrangement and overall inference of the engine parameters that have been calibrated in the past, and a probabilistic expression is proposed, which is expressed by the mean value. Through the statistical analysis of a large number of aircraft data, it is found that these calibration data have a relatively fixed working range, and finding the center curve of the working range can be used as the calibration reference data for the same type of aircraft. The calibration of the engine low-pressure guide vane α1 mainly includes the following steps:

[0032] (1) Statistical historical sample data, the voltage value collected by the engine parameter converter with uniform scale is used as the basic value Σ(1, N), and the maximum value α1max=f(10n) under each scale is obtained;

[0033] (2) Similarly, find the minimum value α1min=f(10n) under each scale;

[0034] (3) Connect the max...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com