Analog simulation method and device for coal seam water injection hole sealing test

A coal seam water injection and similar simulation technology, which is applied to measuring devices, fuel oil testing, material inspection products, etc., can solve problems such as inability to seal and correct accurately, and achieve the effect of improving water injection efficiency and reducing work difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

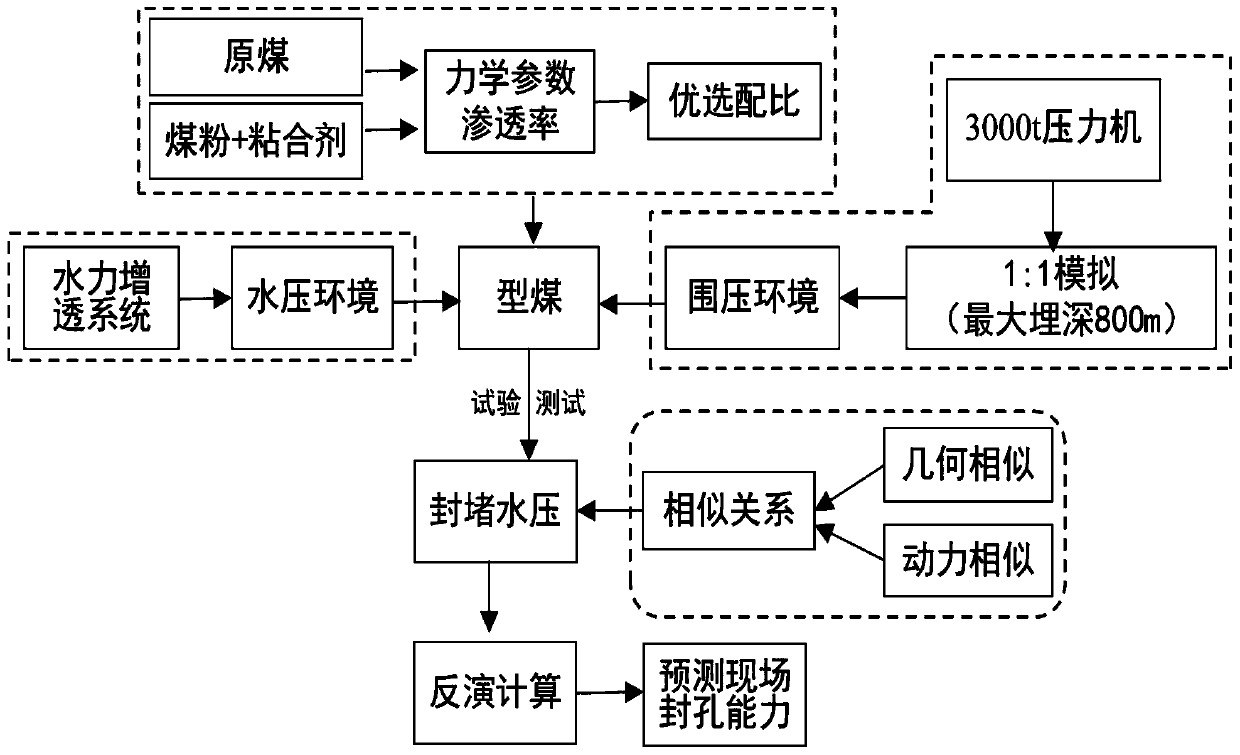

[0056] A similar simulation method for a coal seam water injection sealing hole test, comprising the following steps:

[0057] S1 Determining the experimental parameters: According to the force characteristics of water injection sealing holes, the force model of water injection sealing holes is established, and the simulated similarity ratio is obtained.

[0058] Among them, P 0 , P are the similar model and the actual water injection pressure on site, unit MPa;

[0059] σ 0 , σ are similar model and field actual confining pressure stress, unit MPa;

[0060] D. 0 , D are the similar model and the actual drilling diameter on site, unit mm;

[0061] L 0 , L are the length of the similar model and the actual sealing hole on site, unit mm;

[0062] According to the thickness of the coal seam on site and the parameters affecting the similarity ratio, the experimental parameters and coal sample size specifications are determined. Among them, the parameters affecting the simi...

Embodiment 2

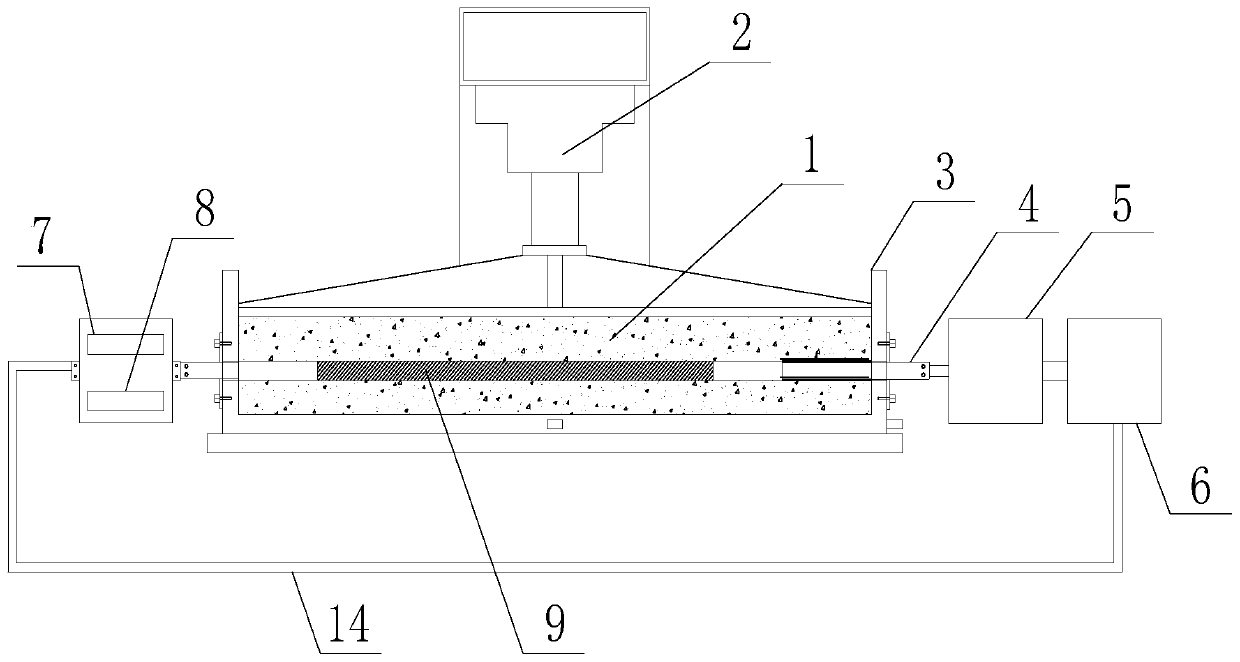

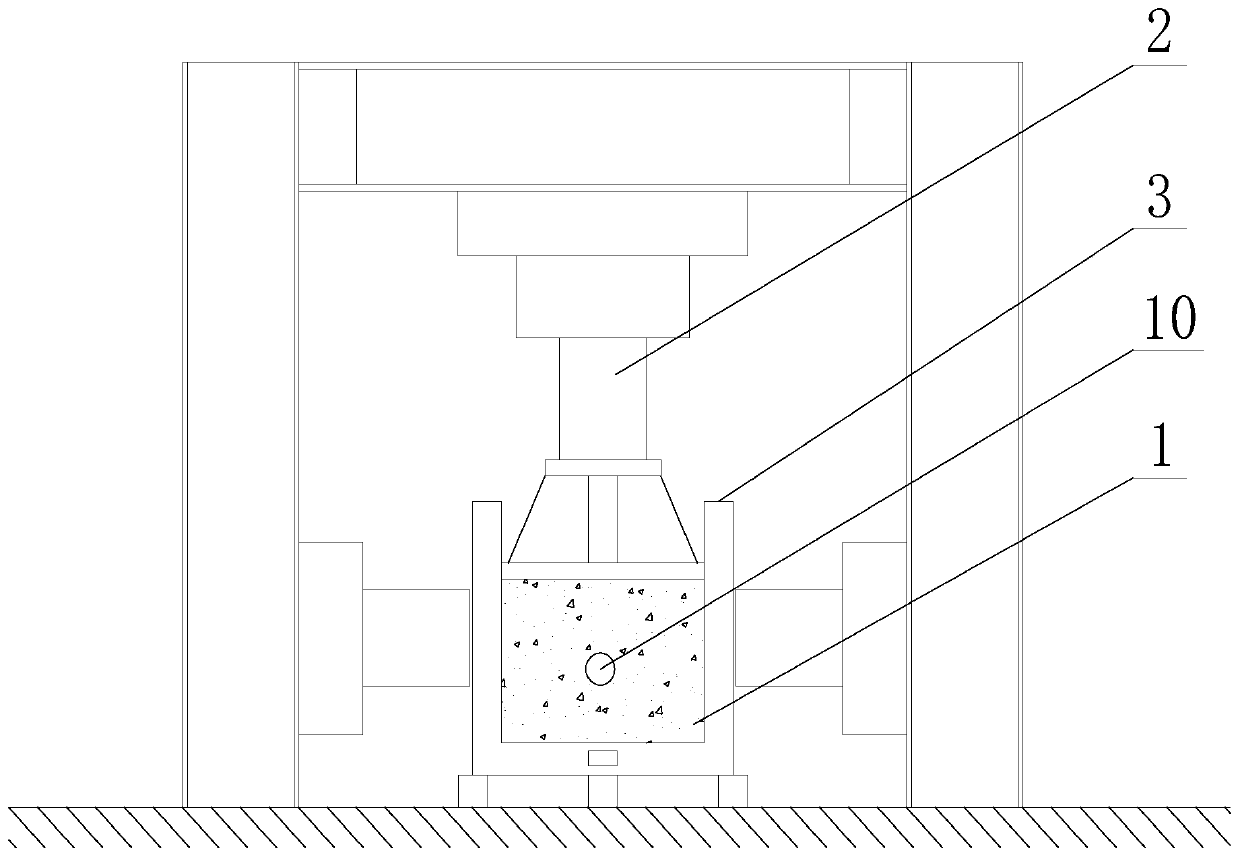

[0114] see Figure 2 to Figure 7 , a similar simulation device for coal seam water injection and hole sealing test, including a briquette pressing device and a water injection system, the briquette pressing device includes a mold box 11, a peripheral support box 3, a transfer beam 13, and is embedded in the briquette sample 1. The water injection pipe is used to form the water injection hole 10 of the briquette sample 1;

[0115] Both ends of the mold box 11 are provided with avoidance holes for water injection pipes, and the avoidance holes are waist-shaped holes; the top end of the mold box 11 is open, and the transfer beam 13 is arranged at the opening of the mold box 11, and the mold box 11 passes through the transfer beam 13 and the confining pressure. The pressurizing device 2 is connected; the peripheral support box 3 has a cavity matched with the circumference of the mold box 11, and the mold box 11 is located in the cavity of the peripheral support box 3;

[0116] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com