Method of recycling waste lead plaster in production process of lead-acid storage battery and application of recycled material

A lead-acid battery, waste lead paste technology, used in lead-acid batteries, lead-acid battery electrodes, battery recycling and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with specific embodiments.

[0024] A method for recycling lead-acid storage battery waste lead plaster, comprising the steps of:

[0025] (1) Use a filter press to remove the water from the acid-leached lead paste and the lead paste in the plate-coated sedimentation tank, then accumulate the water-removed lead paste in a small stainless steel bucket, place it in a closed drying room, and circulate hot air, and the indoor temperature is 80 ℃, after drying for 48 hours, spot-check the water content, complete the drying when the water content is below 1%, and set aside; take the scrap raw plate, use the grid paste separator to vibrate to separate the grid and lead paste, and keep the lead paste for use;

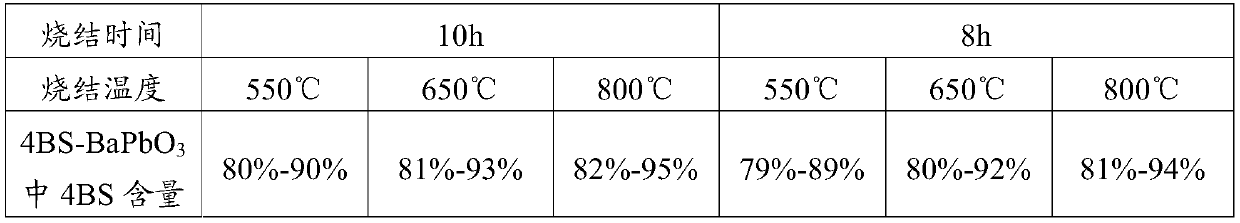

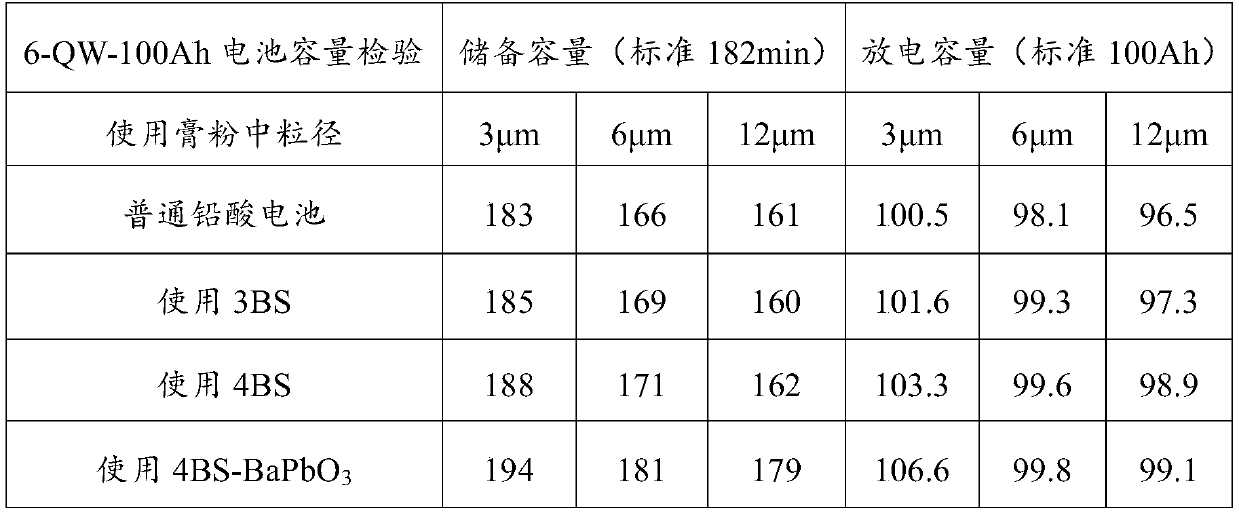

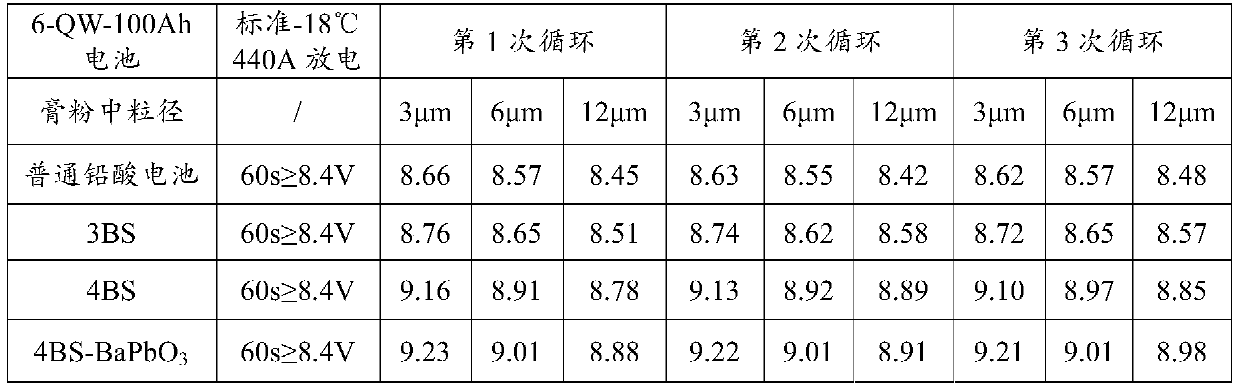

[0026] (2) The waste lead plaster derived from the leaching acid lead paste, the lead plaster of the coating sedimentation tank and the scrapped raw plate are processed according to step (1) a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap