Ring cutting device for cable processing

A loop cutting and cable technology, applied in cable installation devices, cable installation, equipment for dismantling/armored cables, etc., can solve the problems of low efficiency and labor consumption, achieve smooth incision, improve production efficiency, and meet the needs of use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

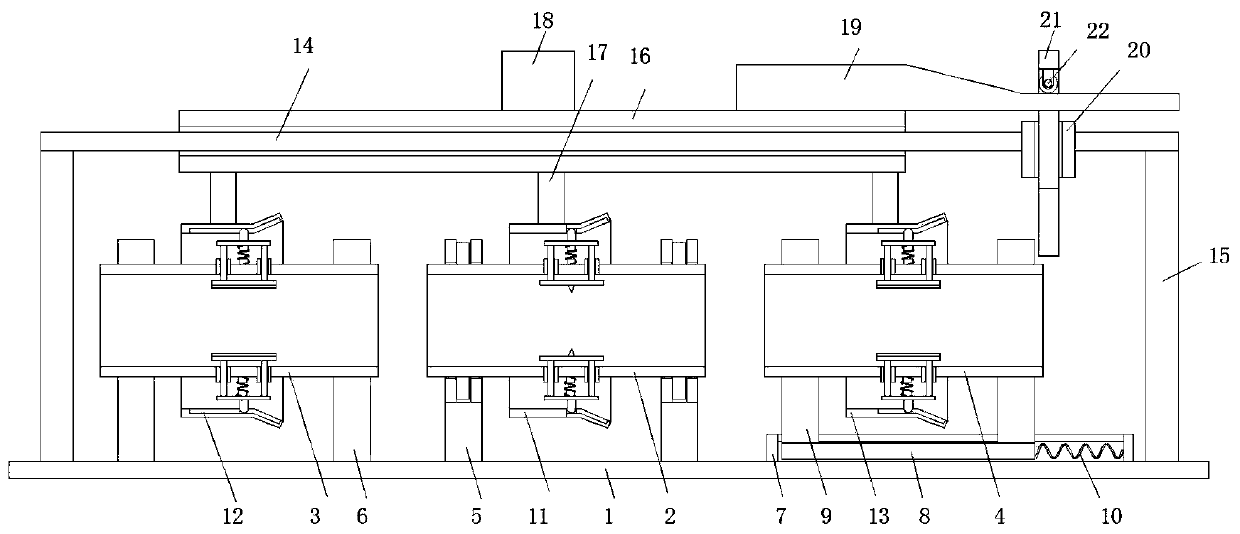

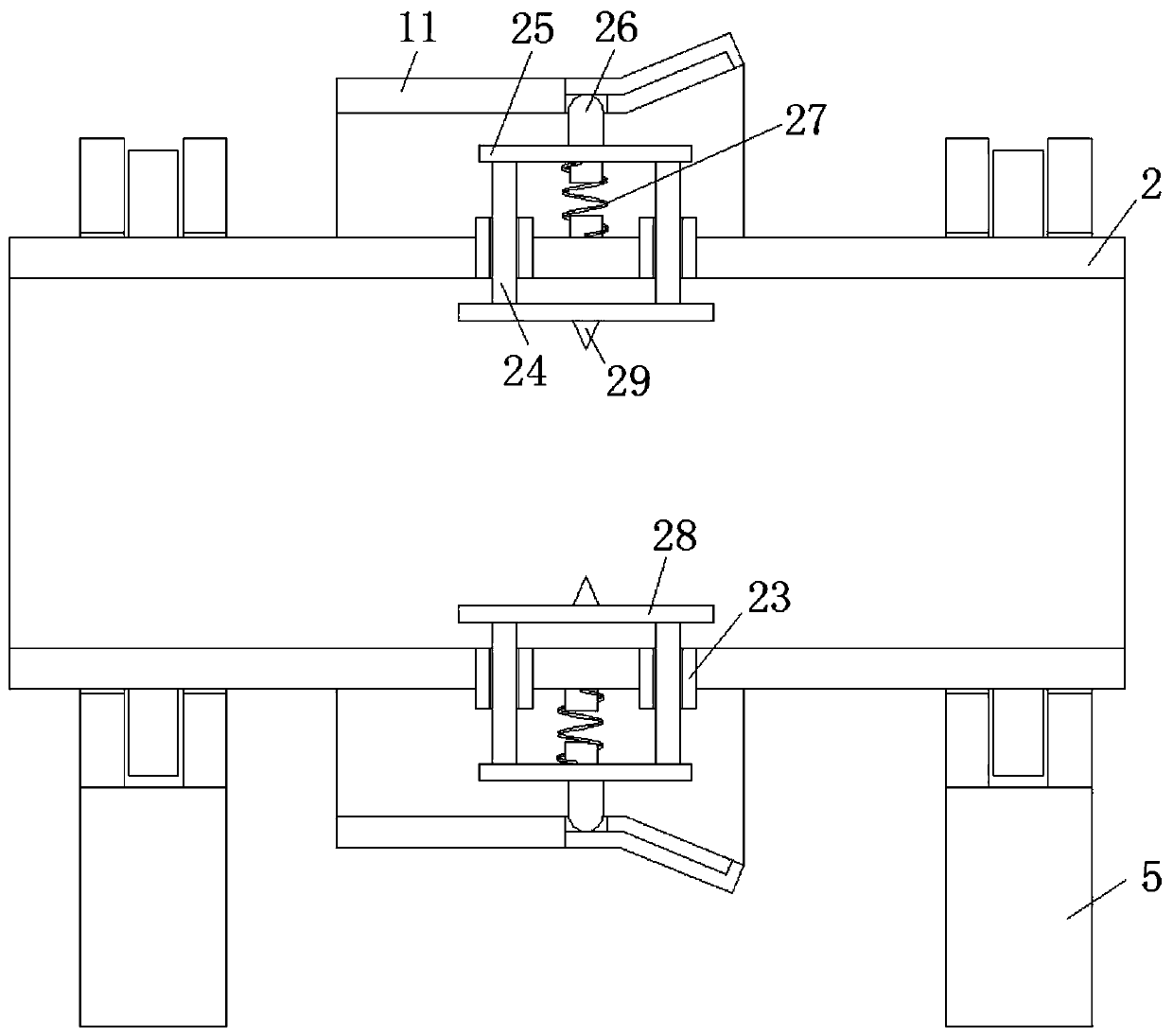

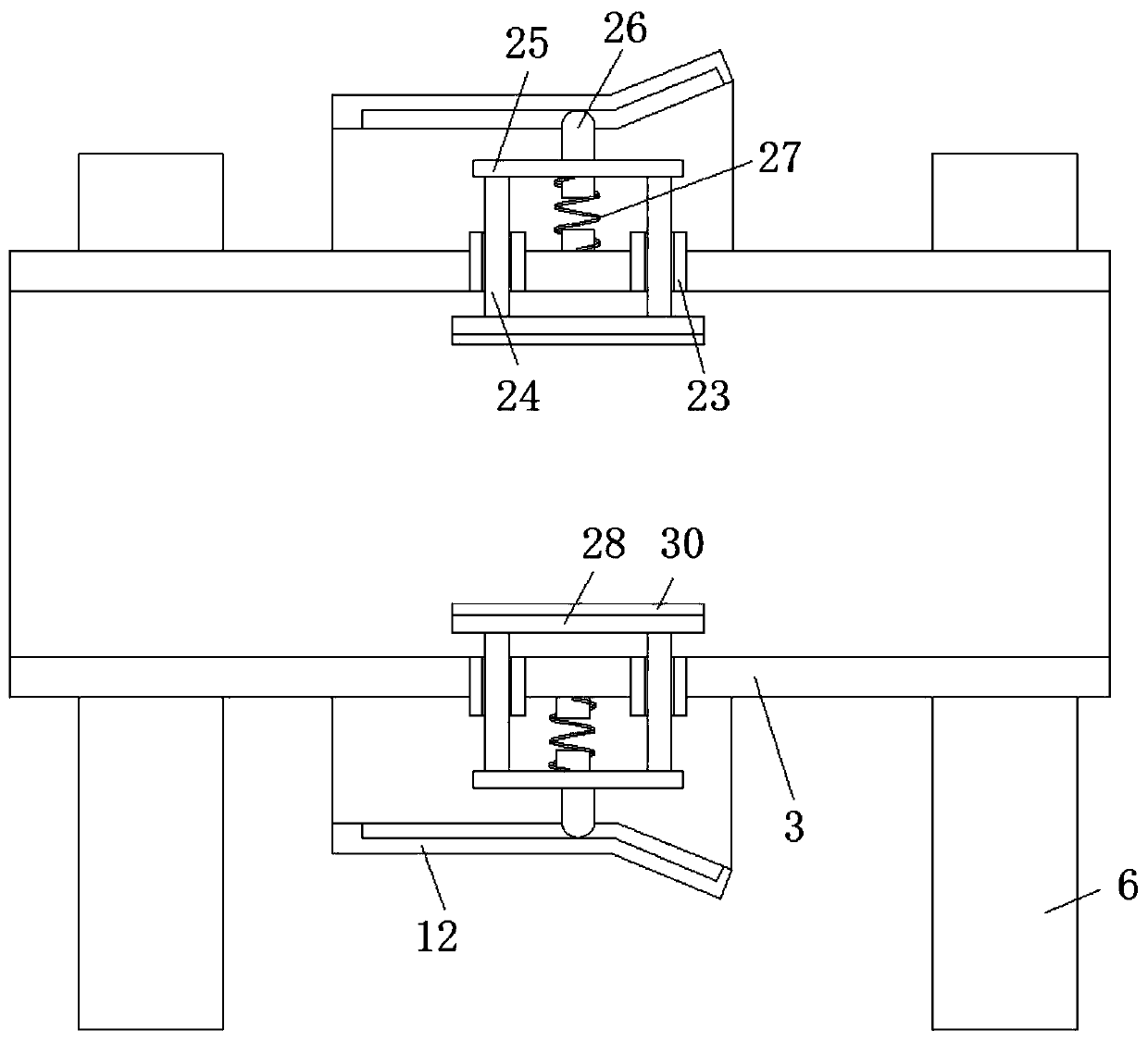

[0023] refer to Figure 1-4 , a ring cutting device for cable processing, comprising a bottom plate 1, a wire barrel 1 2, a wire barrel 2 3 and a wire barrel 3 4 are arranged vertically above the bottom plate 1, a wire barrel 2 3 and a wire barrel 3 4 are respectively arranged on both sides of the wire barrel 1 2, the bottom of the wire barrel 1 2 and the wire barrel 2 3 and the bottom plate 1 are respectively provided with a rotating seat 5 and a fixed base 6, and the top side of the bottom plate 1 is fixedly connected with a sliding seat 7. A chute is provided on the top side of the sliding seat 7, and a slide plate 8 is slidably connected in the chute, and a fixed seat 2 9 is arranged between the top side of the slide plate 8 and the wire barrel 3 4, and the slide plate 8 is far away from the wire barrel 1 2 A spring set 10 is arranged between one side of the chute and the inner wall of the chute, and the outer sides of the wire barrel 1 2, the wire barrel 2 3 and the wire ...

Embodiment 2

[0026] Such as Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the sliding cylinder one 20 is located vertically above the spring group one 10, and the bottom side of the sliding frame 21 and the fixing seat two 9 are far away from the one side of the wire cylinder one 2. side of the top contact connection.

[0027] In this embodiment, the friction force between the track groove 3 and the track rod 26 is prevented from driving the wire barrel 3 4 to move, which will affect the stability of the device.

Embodiment 3

[0029] Such as figure 1 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the top side of the sliding sleeve 16 is fixedly welded with a push handle 18 .

[0030] In this embodiment, it is convenient for people to move the sliding sleeve 16 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com