Defective pixel detection and correction method and device, storage medium and terminal

A detection method and dead point technology, which is applied in the field of image processing, can solve problems such as normal work, abnormal work, and differences, and achieve the effects of accurate dead point judgment, improved accuracy, and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

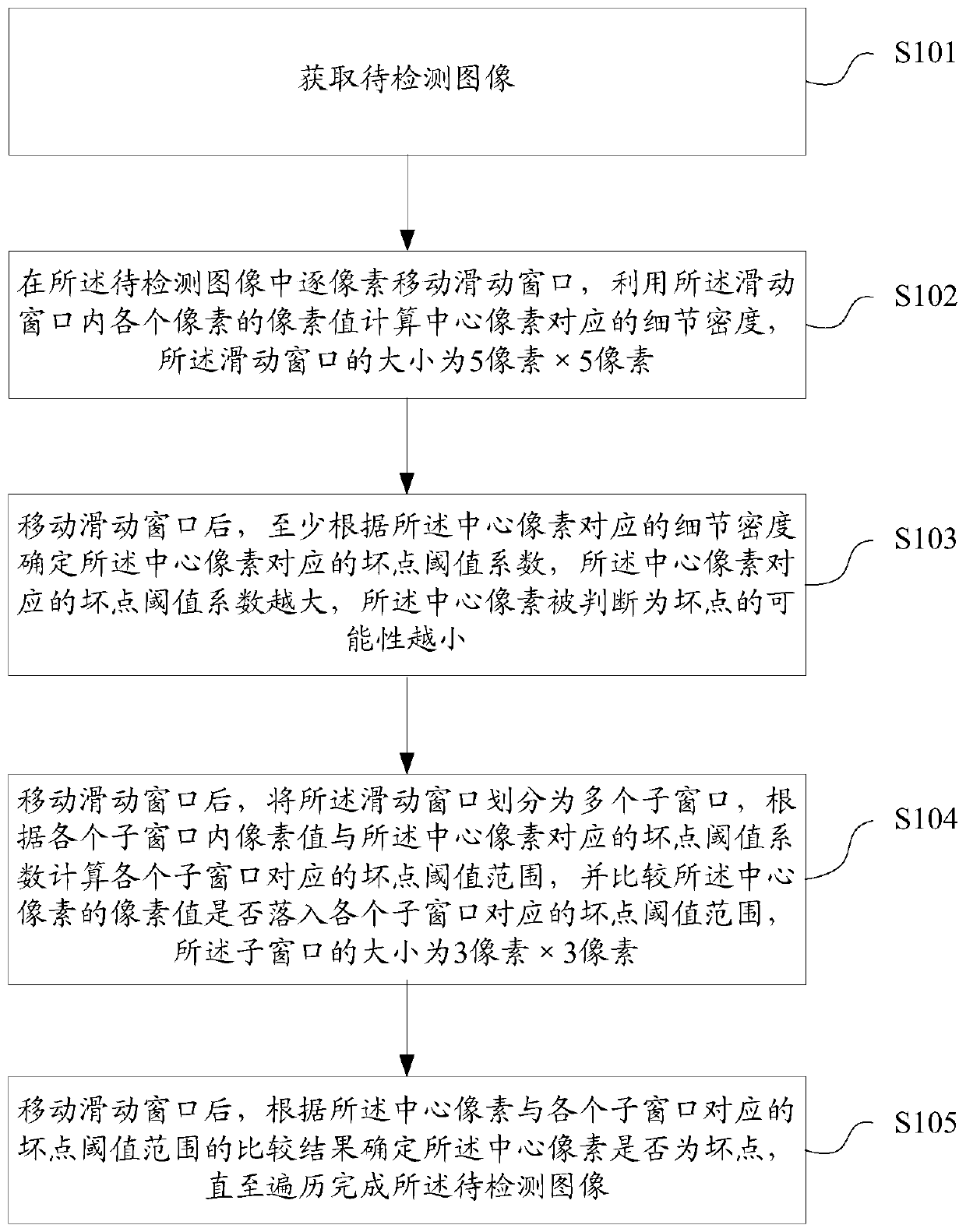

[0044] figure 1 It is a flow chart of a bad point detection method according to an embodiment of the present invention.

[0045] The dead point detection method in this embodiment can be used on the side of a terminal device capable of image processing, such as an image sensor, a digital camera or a digital video camera, etc., that is, it can be executed by the terminal device figure 1 The individual steps of the method shown.

[0046] figure 1 The illustrated method may include the steps of:

[0047] Step S101: acquiring an image to be detected;

[0048] Step S102: moving the sliding window pixel by pixel in the image to be detected, using the pixel values of each pixel in the sliding window to calculate the detail density corresponding to the central pixel, the size of the sliding window is 5 pixels×5 pixels;

[0049] Step S103: After moving the sliding window, at least determine the dead pixel threshold coefficient corresponding to the central pixel according to the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com