Valve mechanism, solenoid suction valve mechanism and high pressure fuel pump

A valve mechanism and valve core technology, used in fuel injection pumps, fuel injection devices, machines/engines, etc., can solve the problems of wear of the suction valve seat, failure of the suction valve to seal, and poor sealing performance, so as to improve flow control. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

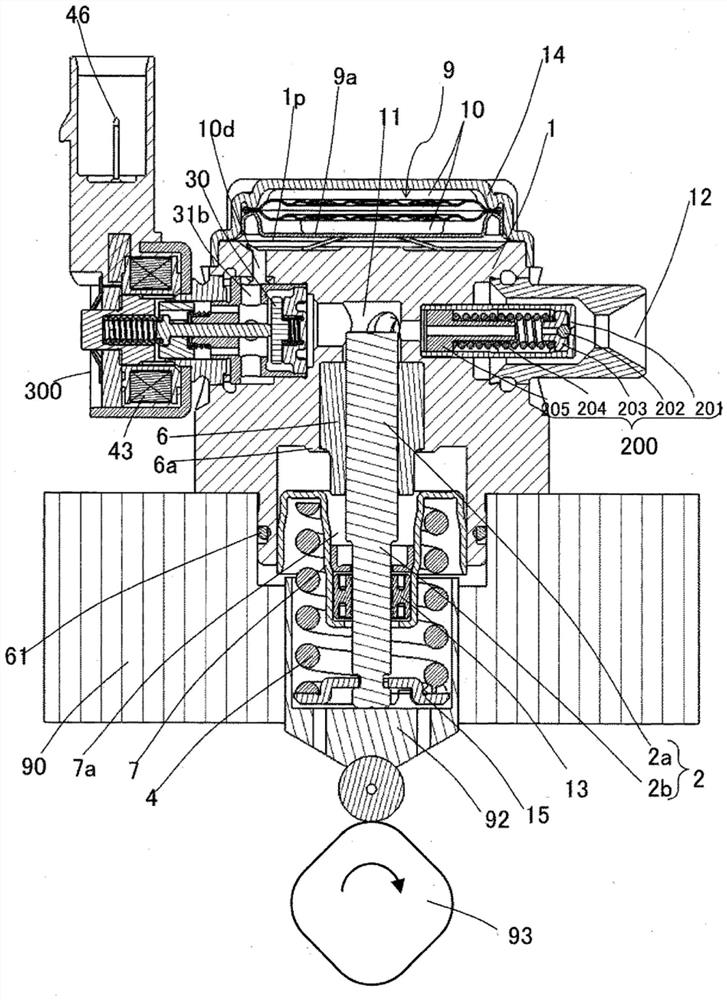

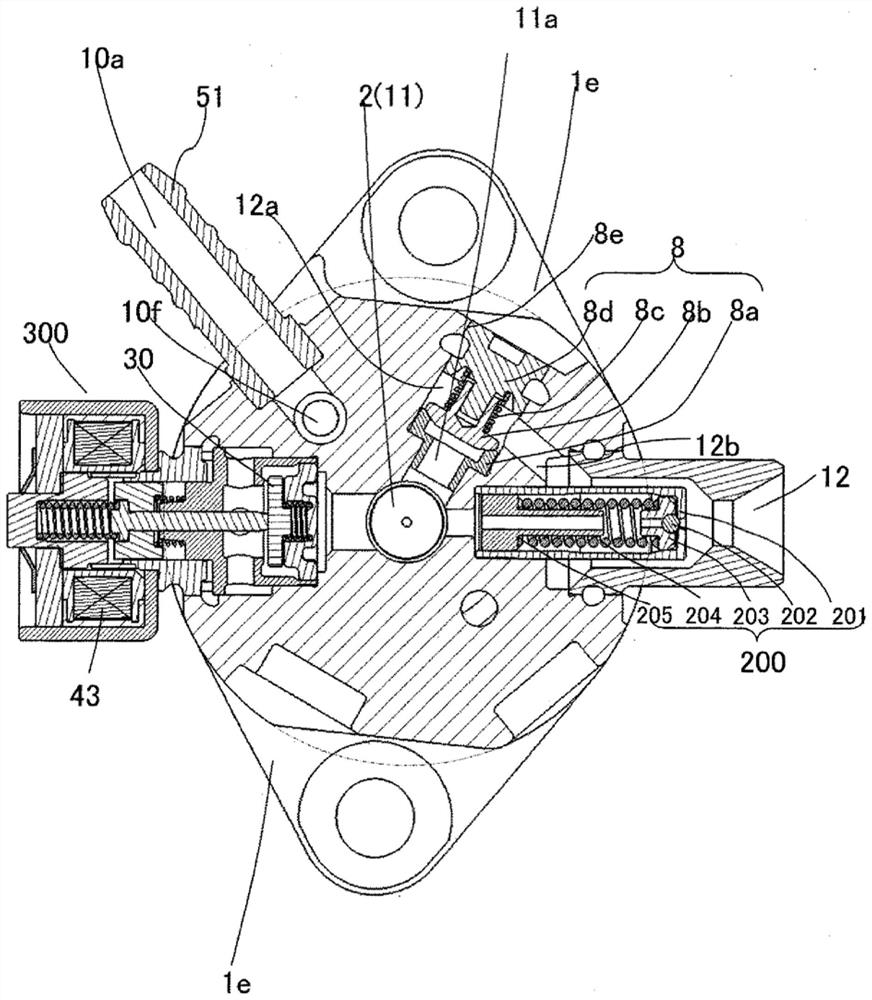

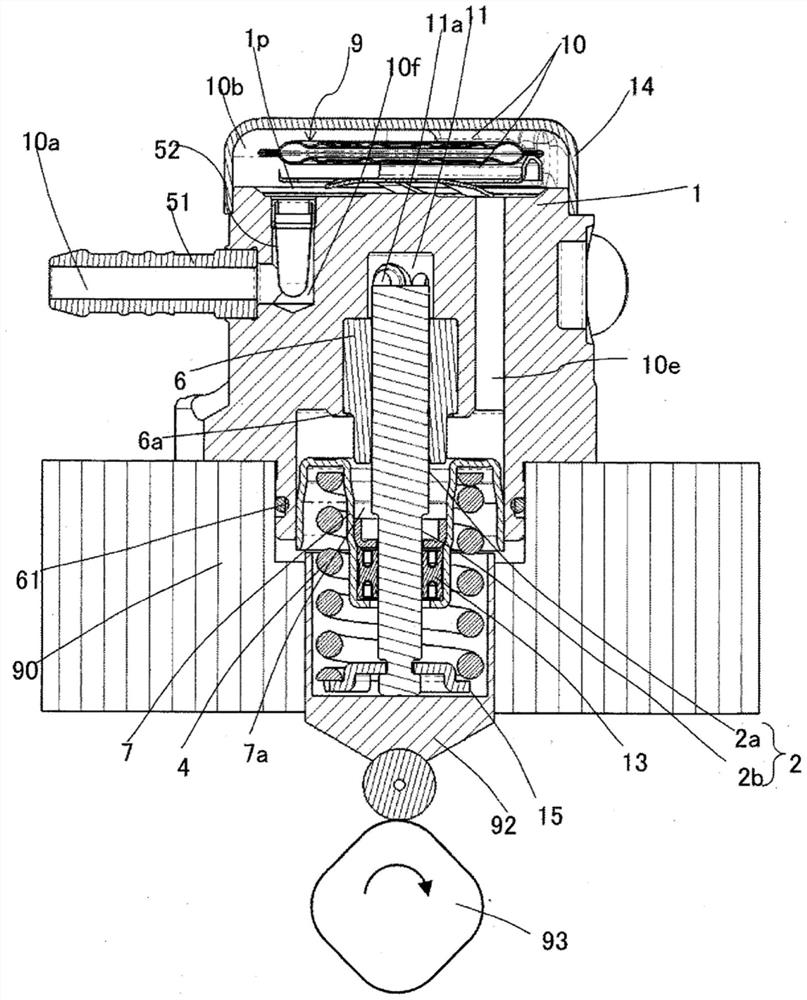

[0027] (overall composition)

[0028] First, use Figure 5 The shown overall configuration diagram of the engine system explains the configuration and operation of the system. The part enclosed by the dotted line represents the main body of the high-pressure fuel pump, and the mechanisms and parts shown in the dotted line represent that they are integrally mounted on the pump body 1 .

[0029] The fuel of the fuel tank 20 is sucked by the feed pump 21 according to a signal from an engine control unit 27 (hereinafter referred to as ECU). The fuel is pressurized to the proper feed pressure and delivered through the suction line 28 to the low pressure fuel suction port 10a of the high pressure fuel pump. From the low-pressure fuel suction port 10a through the suction joint 51 (refer to figure 2 ) to the suction port 31b of the electromagnetic suction valve mechanism 300 constituting the capacity variable mechanism via the metal damper 9 (pressure pulsation reducing mechanism)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com