An environmentally friendly spraying device for flange production

A spraying device and flange technology, which is applied in the field of environmentally friendly spraying devices for flange production, can solve the problems of easy to cover flanges, low processing efficiency, and poor versatility, and achieve the effects of avoiding uneven spraying and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

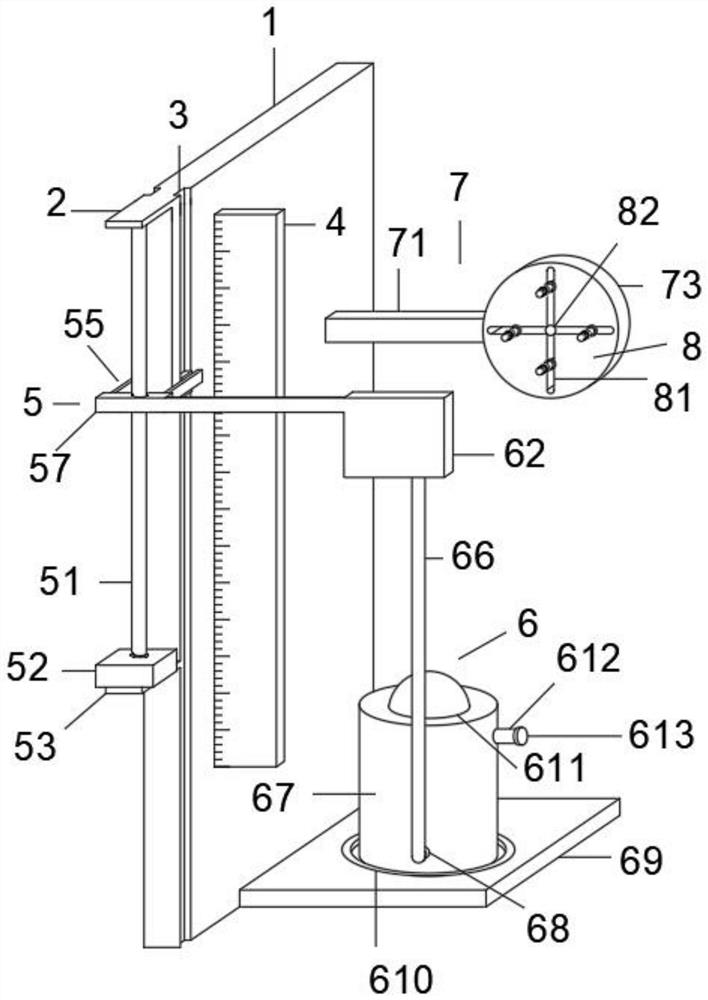

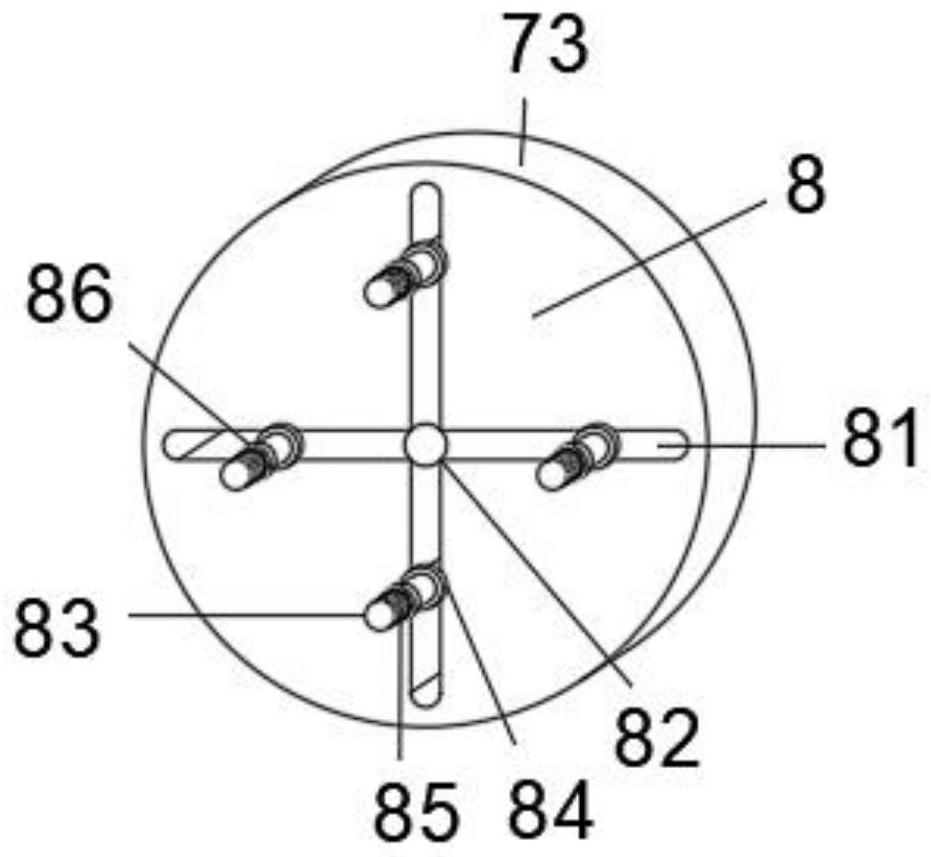

[0023] Embodiment 1: as Figure 1-5 As shown, this specific embodiment adopts the following technical solutions: an environmentally friendly spraying device for flange production, including a support plate 1, the top of the support plate 1 is fixedly connected with a top connecting plate 2, and one side of the top connecting plate 2 Both sides of the support plate 1 are dug with slots 3, the side of the support plate 1 away from the top connecting plate 2 is fixedly connected with a scale 4, and the bottom of the top connecting plate 2 is provided with a transmission mechanism 5, One side of the transmission mechanism 5 is connected with a spraying mechanism 6, a rotating mechanism 7 is arranged on the support plate 1 on the side of the spraying mechanism 6 away from the transmission mechanism 5, and a fixing mechanism 8 is arranged on the rotating mechanism 7;

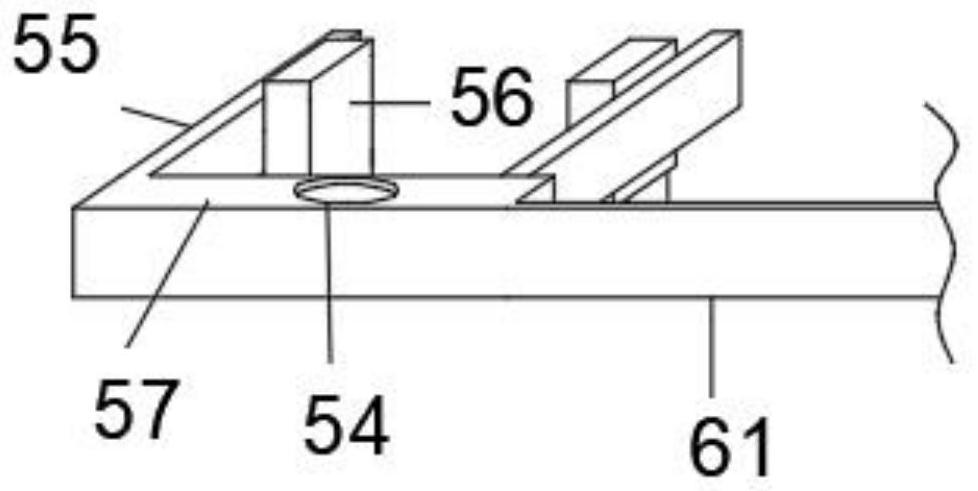

[0024] Wherein, the transmission mechanism 5 includes a threaded rod 51, the threaded rod 51 is rotationally connec...

Embodiment 2

[0033] Embodiment 2: Replace the threaded rod 51 and the servo motor 52 with an electric telescopic rod, one end of the electric telescopic rod is fixedly connected to the No. 1 plate 57, the other end of the electric telescopic rod is fixedly connected to the motor mounting plate 53, and the The height of No. 1 plate 57 is telescopically adjusted, and the adjustment range of the electric telescopic rod is small, and the adjustment is more precise, which is suitable for finishing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com