Shock absorber capable of adjusting height of vehicle body

A technology of body height and shock absorber, which is applied in vehicle springs, vehicle parts, elastic suspension, etc., can solve the problems that affect the vehicle model planning of OEMs, unfavorable model development costs, and reduce customer experience, so as to achieve simple structure and practicality Strong performance and few adjustment parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

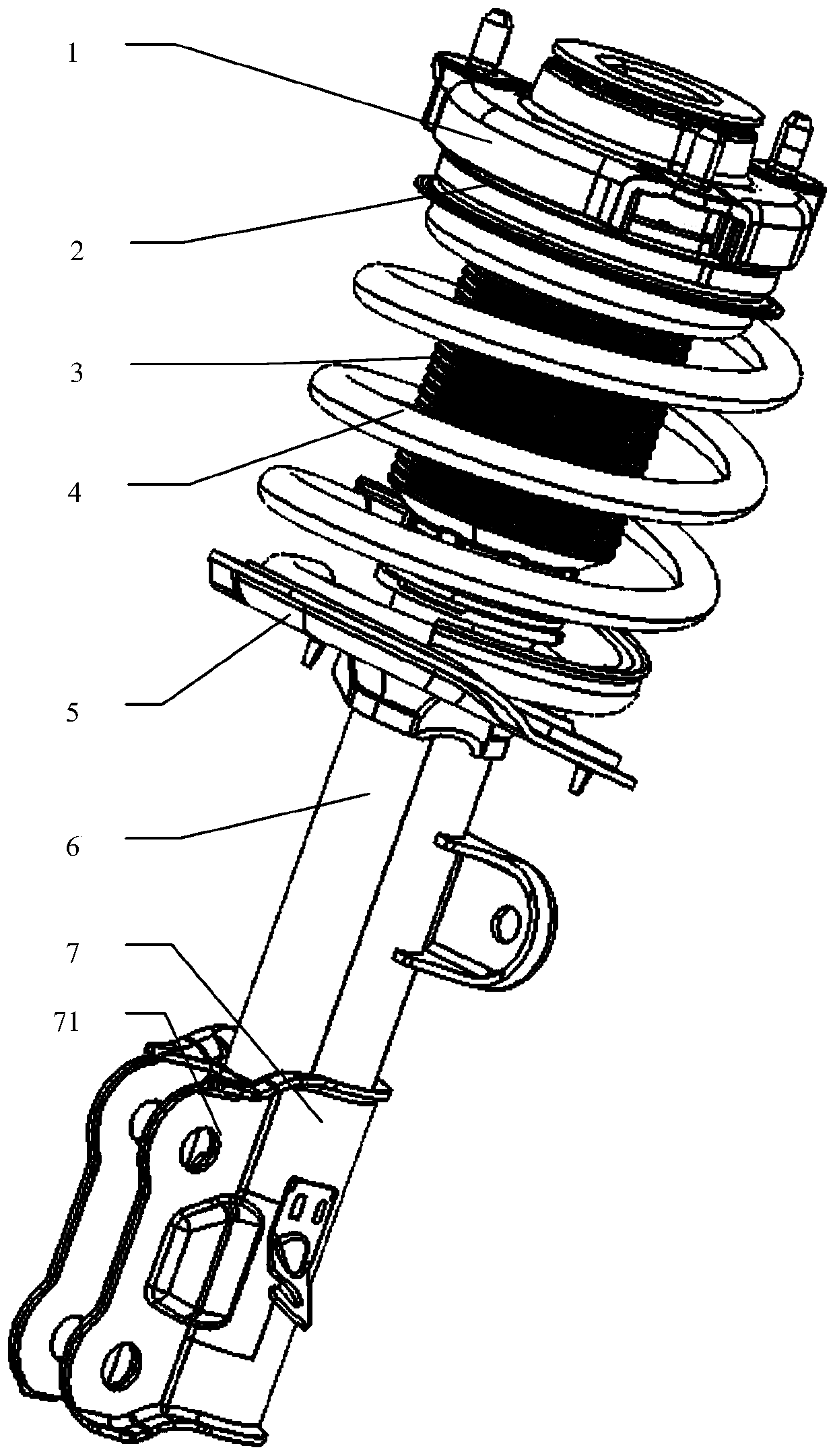

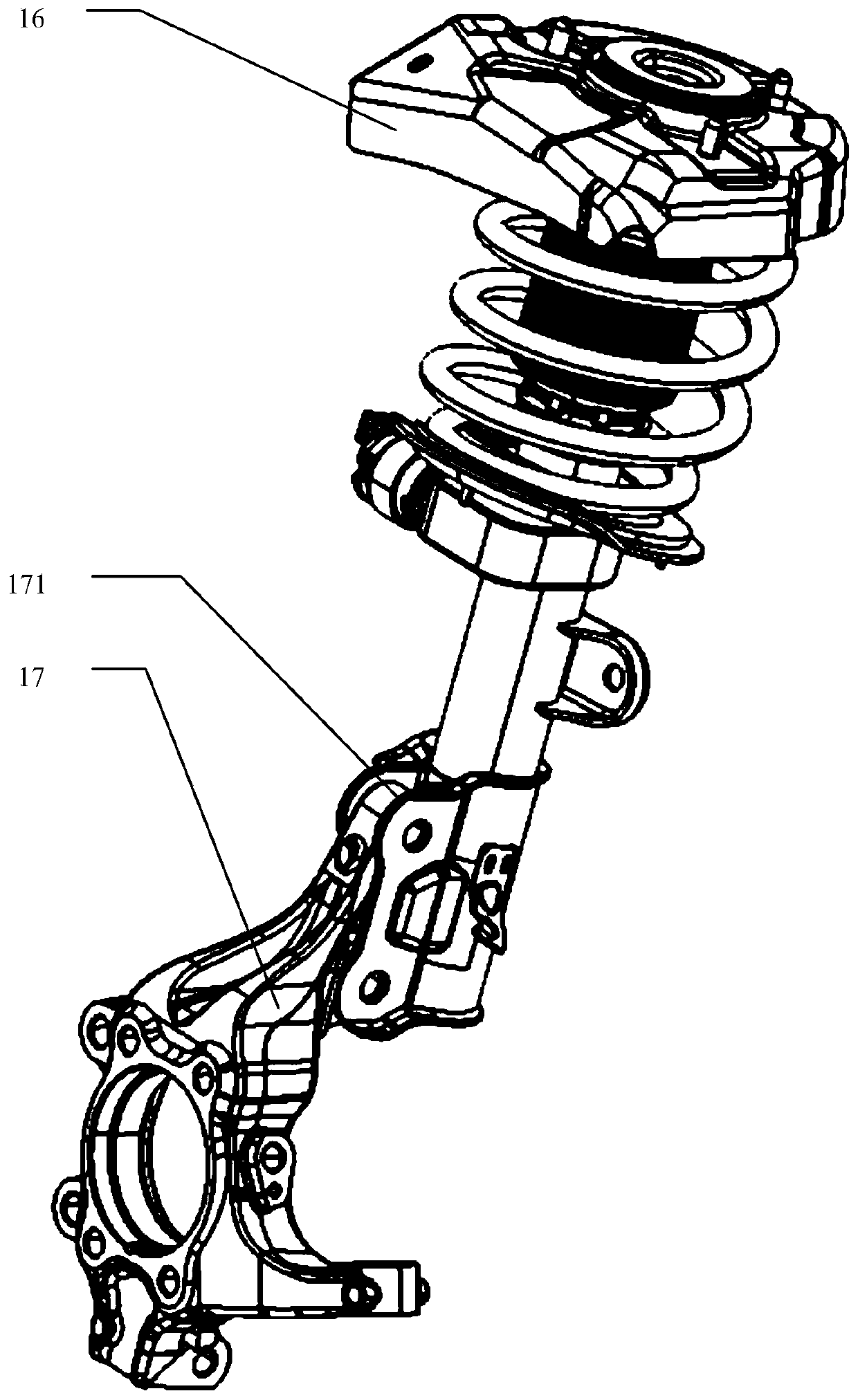

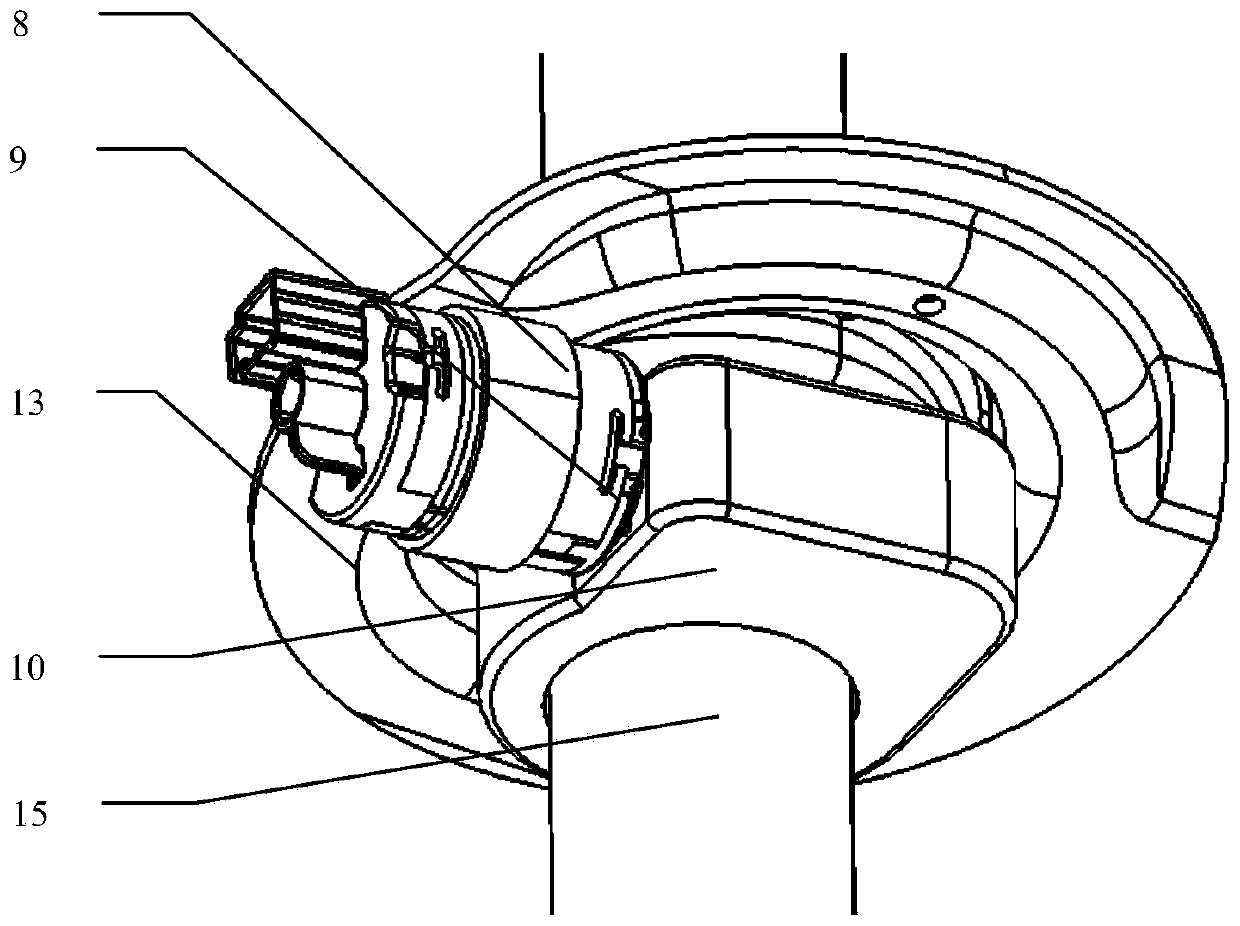

[0035] Embodiment 1: see figure 2 , image 3 and Figure 4 ,and figure 1 The same as the traditional shock absorber shown, the shock absorber of the present invention has traditional shock absorber components such as upper mounting base 1, bearing 2, spring 4, shock absorber dust cover 3, steering knuckle bracket 7, etc., has traditional shock absorber basic functions of the device. The present invention modifies and optimizes the structure of the spring disk 5 and the oil storage cylinder 6 of the traditional shock absorber. The structurally changed parts include the spring disk 13 and the threaded oil storage cylinder 15 that can move along the oil storage cylinder. Parts such as motor 9, worm screw 10, and worm screw 11 that are used for adjustment, all parts work together to realize the raising and lowering of the vehicle.

[0036] see Figure 8 , Figure 10 , in this embodiment, the spring plate 13 that can move along the oil storage cylinder is installed on the oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com