Method for high yield of D-(-)-Pantolactone hydrolase

A technology of pantolactone and hydrolase, which is applied in the field of mutagenesis and high-production D-pantolactonase strains, and can solve the problems of environmental pollution, separation difficulty, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The purpose of this example is to screen out suitable strains to be mutated.

[0032] Collect multiple strain samples from the soil of Guzhen Fermentation Industrial Park in Anhui Province, add sterile water to shake on the shaker, take the supernatant after standing still, spread it on the primary screening medium after dilution, and cultivate at 28°C After 3 days, the strain with the largest diameter of the color-changing circle was selected as the strain to be mutated.

Embodiment 2

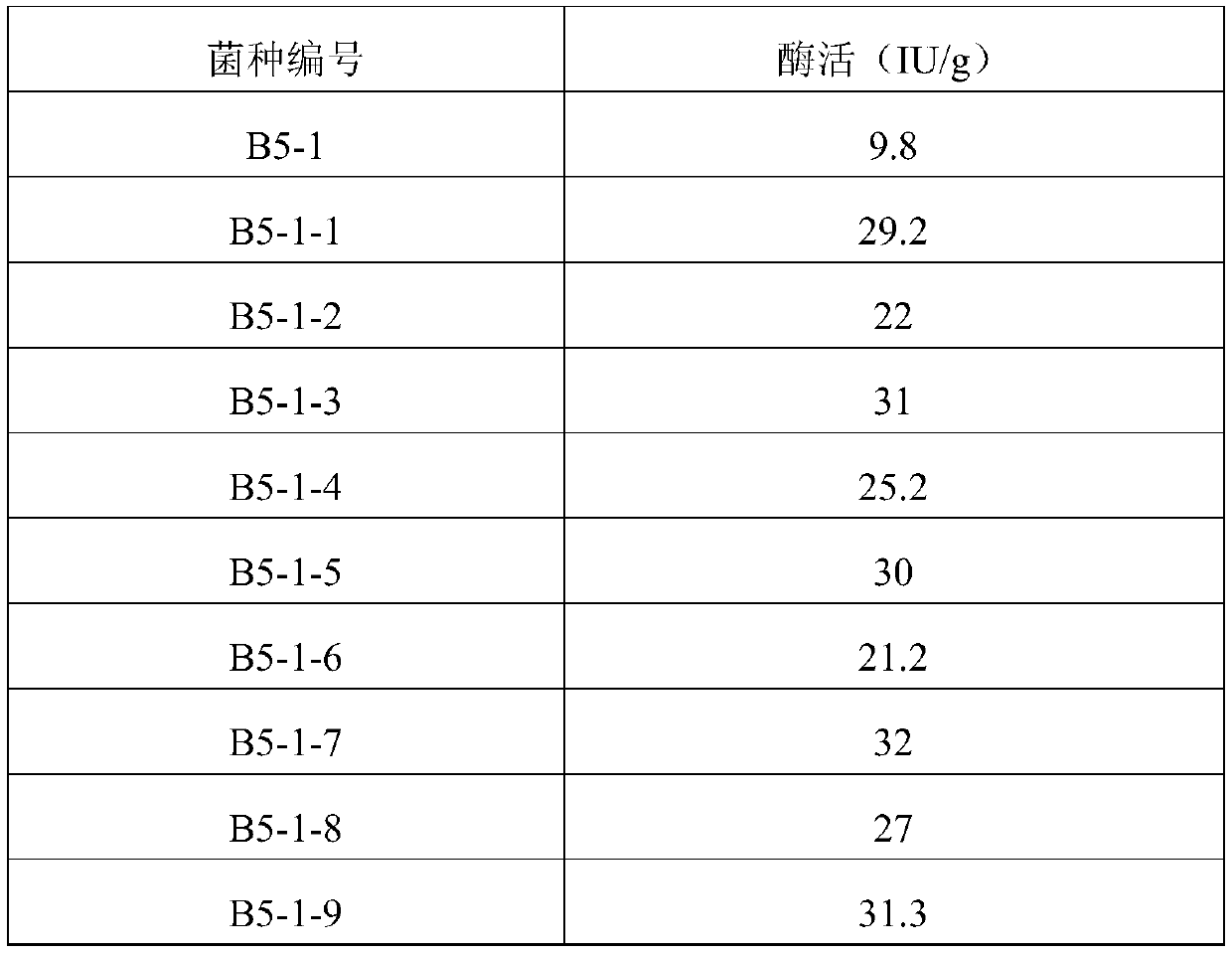

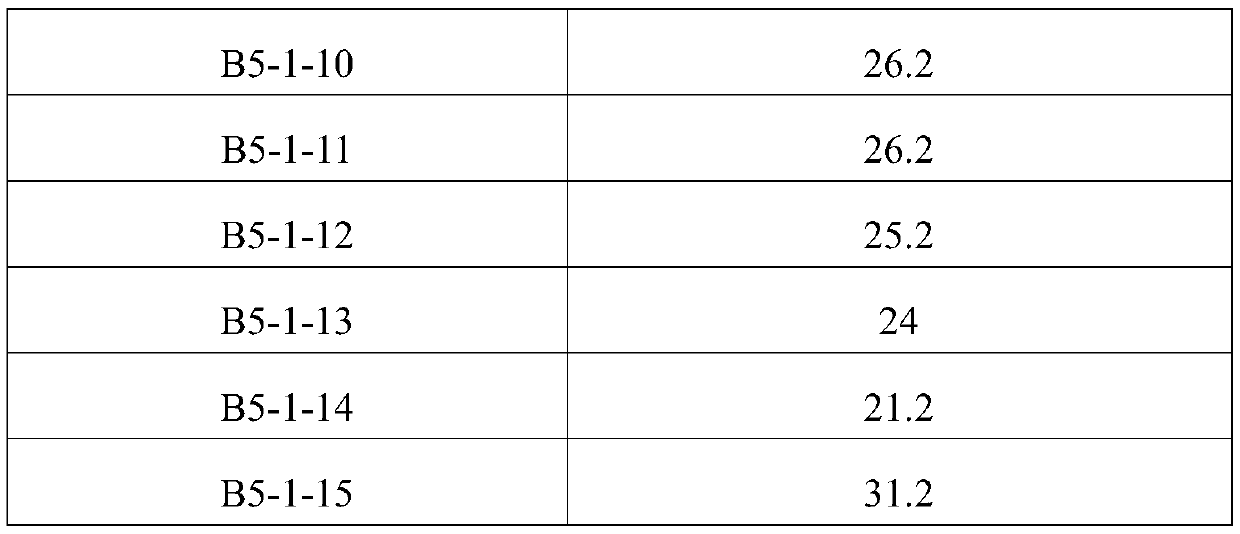

[0034] The purpose of this example is to obtain strains capable of high production of D-pantolactone hydrolase by mutagenesis. The specific operation is:

[0035] (a) the strains to be mutated obtained by the preliminary screening of Example 1 are first inserted into the primary seed liquid, and the ingredients contained in every liter of the primary seed liquid medium are: 13g glycerol, 13g soybean peptone, 3g corn steep liquor dry powder, 3g yeast extract, 6g soybean meal powder, pH 7.0; culture at 28°C, 180rpm to the logarithmic growth phase, centrifuge the supernatant of the bacterial liquid under aseptic operation, and use sterile physiological saline to prepare the bacterial cell to a concentration of for 10 6 ~10 8 cells / mL of bacterial suspension.

[0036] (b) Take 10 μL of the bacterial suspension and spread it evenly on the slide, and use ARTP instrument to irradiate, use 99.99% helium as the working gas, the air flow rate is 10L / min, the power supply is 120W, and...

Embodiment 3

[0043] The purpose of this embodiment is to use the target bacterial strain obtained in Example 2 to carry out the fermentation production of D-pantolactone hydrolase, and the specific operations are:

[0044] The target mutagenic strain B5-1-7 obtained in Example 2 was inserted into the primary seed liquid culture medium with an inoculum size of 1%, and cultivated at 28°C and 180rpm for 24h to obtain the primary seed liquid; then inoculated with 10% Add the primary seed liquid to the secondary seed liquid culture medium, and cultivate it at 28°C and 180rpm for 24 hours to obtain the secondary seed liquid; then insert the secondary seed liquid into 10m 3 In the fermentation medium, cultivate at 28°C and 150rpm for 36 hours. After the fermentation, the enzyme activity of the fermentation broth was measured to be 82.3IU / g; the D-pantolactone hydrolase in the fermentation broth was extracted by conventional methods.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap