Pre-grouting type semi-grouting sleeve structure and construction method

A semi-grouting sleeve and grouting material technology, which is applied to structural elements, building components, building structures, etc., can solve problems such as complex grouting operations and difficult quality assurance, so as to simplify the construction process, improve construction efficiency, and avoid The effect of the grouting operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

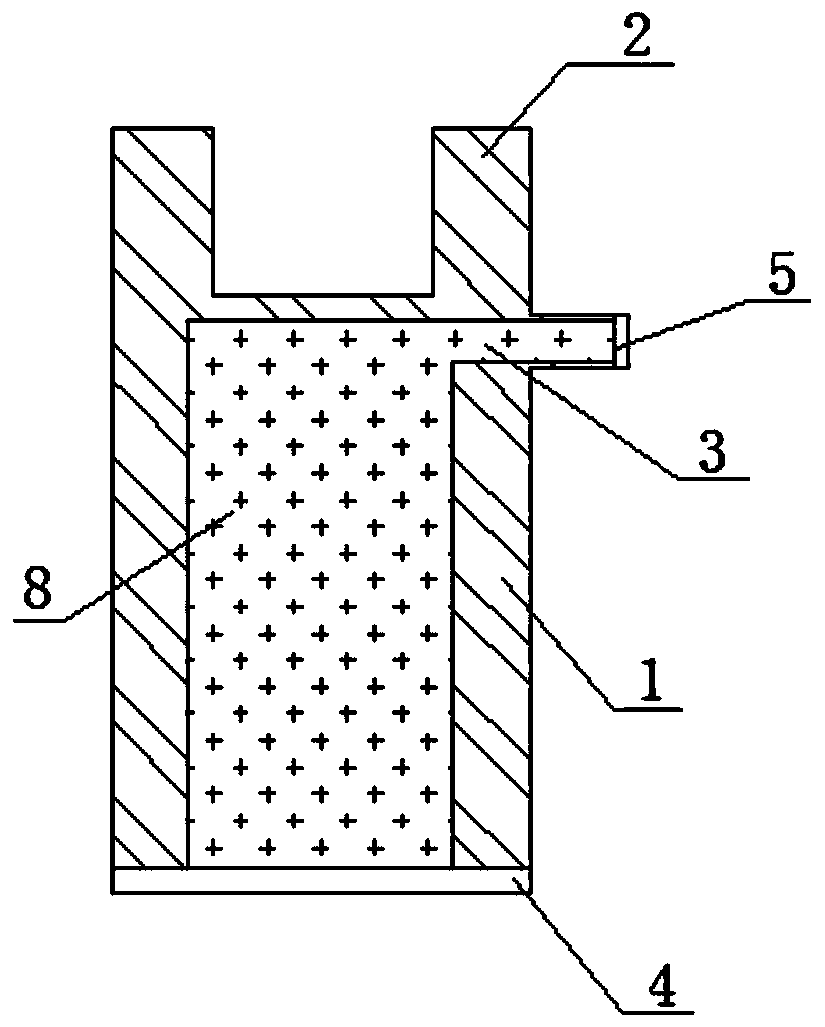

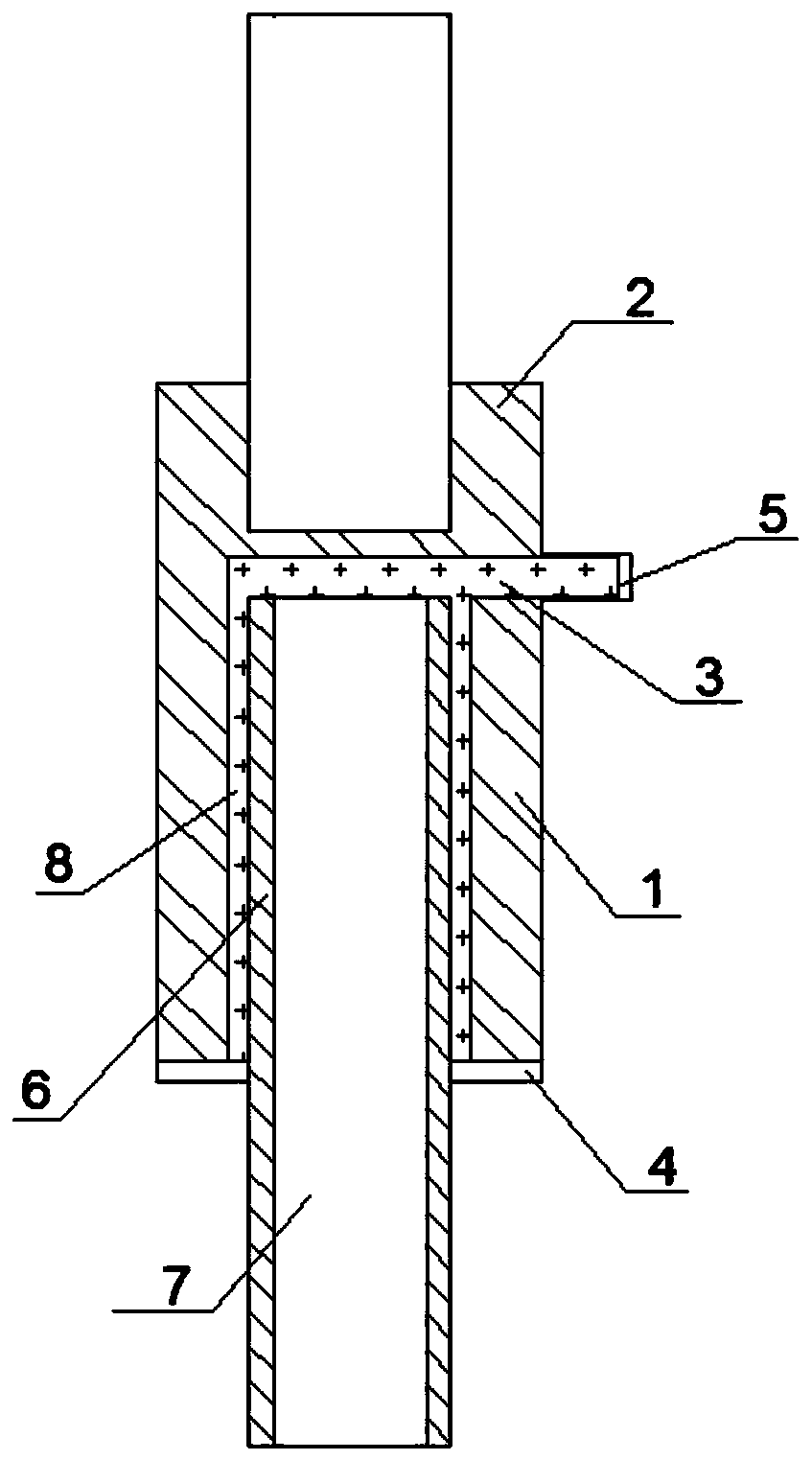

[0023] refer to Figure 1 to Figure 2 , this embodiment provides a pre-grouting semi-grouting sleeve structure, including a grout cylinder 1, and a steel bar connector 2 arranged outside the bottom of the grout cylinder 1, the wall of the grout cylinder 1 is provided with The slurry overflow hole 3, the mouth of the slurry cylinder 1 is provided with a cylinder mouth cover 4, the overflow opening of the slurry overflow hole 3 is provided with a slurry overflow cover 5, and the slurry cylinder 1 is filled with a grouting material 8.

[0024] A kind of pre-grouting semi-grouting sleeve structure of this embodiment, the grouting material 8 is prefabricated in the grouting material cylinder 1, when constructing the pre-grouting type semi-grouting sleeve structure, only need to directly insert the steel bar 7 to be connected The slurry tank 1 gets final product. Compared with the traditional grouting sleeve construction process, the grouting operation is eliminated, the constructi...

Embodiment 2

[0029] This embodiment provides a construction method for the pre-grouted semi-grouting sleeve structure described in Embodiment 1.

[0030] The technical characteristics of the construction method of the pre-grouting type semi-grouting sleeve structure of the present embodiment are as follows, comprising the steps:

[0031] In the first step, the grouting material 8 is filled in the grouting material cylinder 1 of the pre-grouting type semi-grouting sleeve structure;

[0032] In the second step, during the prefabricated component manufacturing process, the pre-grouted half-grouted sleeve structure is embedded in the prefabricated component, and the steel bar connector 2 of the pre-grouted half-grouted sleeve structure is connected to the internal steel bars of the prefabricated component;

[0033] The third step is to remove the overflow cover 5;

[0034] The fourth step is to insert the steel bar 7 to be connected into the slurry cylinder 1 from the mouth of the slurry cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com