Coal mine universal high-pressure grouting pipe quick connecting device and using method thereof

A technology of high-pressure grouting and quick connection, which is applied in the direction of sleeve/socket connection, pipe/pipe joint/fitting, mining equipment, etc., which can solve the problems of high cost, waste of time, no diameter change, etc., and achieve easy operation , improve work efficiency, and have a reasonable overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

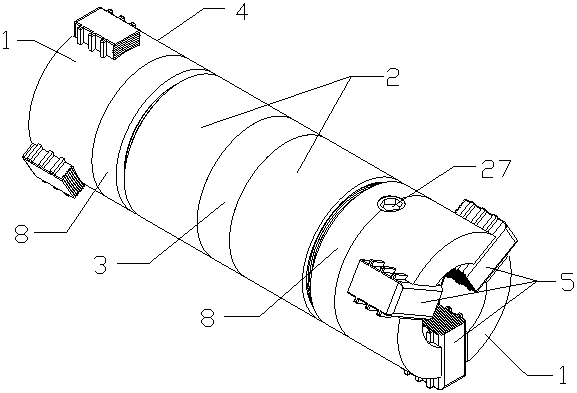

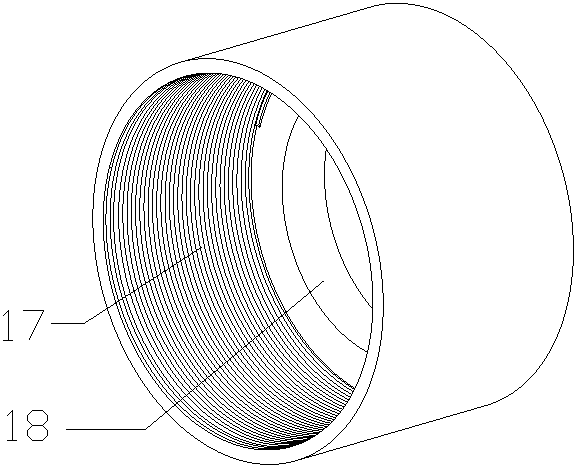

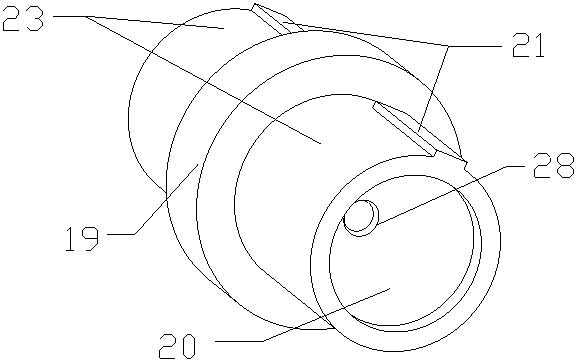

[0033] Such as Figure 1-10 As shown, a universal high-pressure grouting pipe quick connection device for coal mines includes a three-jaw clamp fixing device 1, and the three-jaw clamp fixing device 1 includes a chuck body shell 4, movable jaws 5, and a toothed plate 6 , a bevel gear 7, a disc body connector 8, the chuck body shell 4 is a cylindrical barrel as a whole, and one end of the chuck body shell 4 is provided with a rectangular cutout 9, and the chuck body shell 4 The other end is fixedly connected with a disc body connector 8, and a movable claw 5 is slidably arranged in the rectangular cutout 9, and the bottom surface of the movable claw 5 is provided with arc tooth lines 10; the top surface of the toothed disc 6 is provided with There are helical tooth lines 12, and the bottom surface of the toothed plate 6 is provided with conical tooth lines 13, and the toothed plate 6 and the movable jaw 5 are meshed and connected by the spiral tooth lines 12 and the arc tooth l...

Embodiment 2

[0043] Such as Figure 1-9 As shown, a universal high-pressure grouting pipe quick connection device for coal mines includes a three-jaw clamp fixing device 1, and the three-jaw clamp fixing device 1 includes a chuck body shell 4, movable jaws 5, and a toothed plate 6 , a bevel gear 7, a disc body connector 8, the chuck body shell 4 is a cylindrical barrel as a whole, and one end of the chuck body shell 4 is provided with a rectangular cutout 9, and the chuck body shell 4 The other end is fixedly connected with a disc body connector 8, and a movable claw 5 is slidably arranged in the rectangular cutout 9, and the bottom surface of the movable claw 5 is provided with arc tooth lines 10; the top surface of the toothed disc 6 is provided with There are helical tooth lines 12, and the bottom surface of the toothed plate 6 is provided with conical tooth lines 13, and the toothed plate 6 and the movable jaw 5 are meshed and connected by the spiral tooth lines 12 and the arc tooth li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com