A soil sampling device

A sampling device and soil technology, applied in the direction of sampling devices, etc., can solve the problems of sampler movement, damage to the original state of soil structure or shape, and affect soil sampling, so as to achieve the effect of stable sampling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

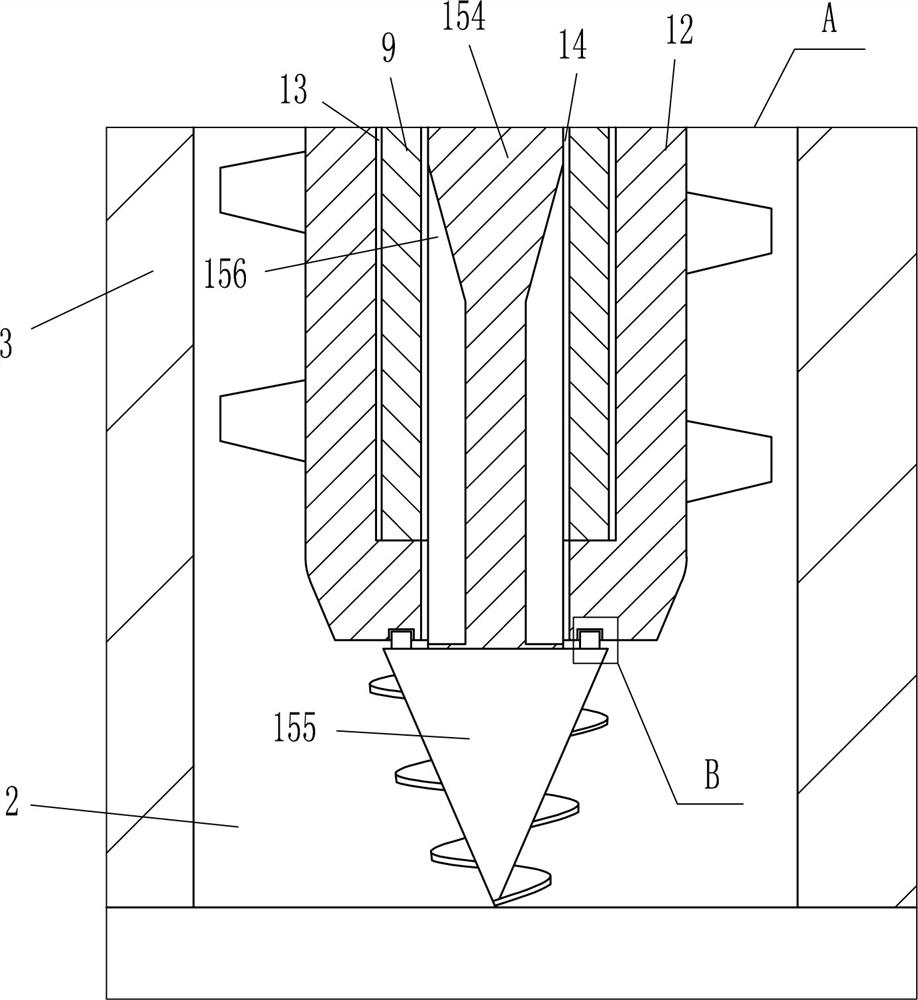

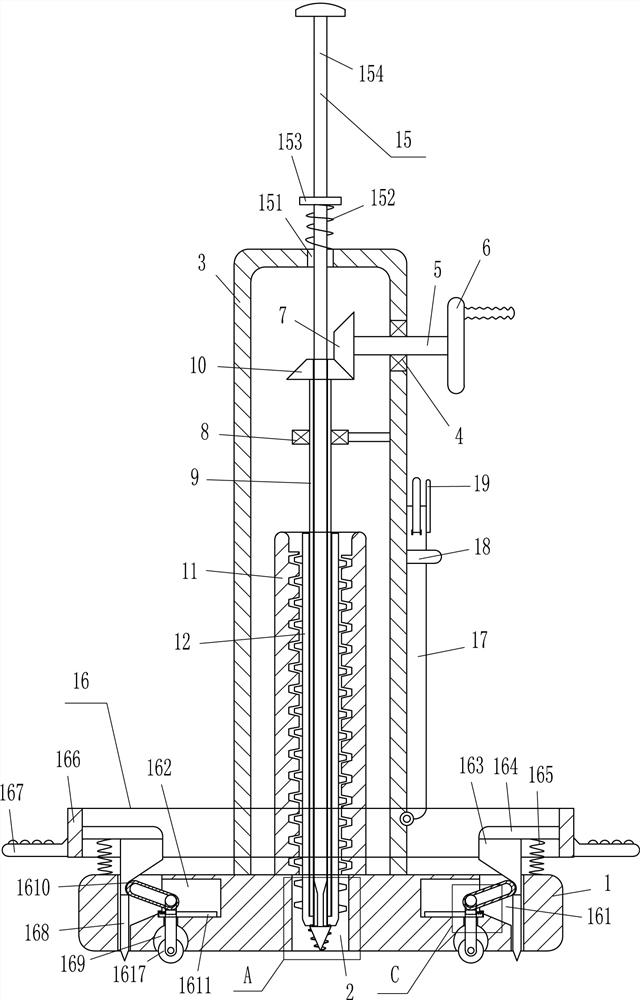

[0021] see Figure 1-3 , this application provides a soil sampling device, including a base 1, a frame 3, a first bearing seat 4, a rotating shaft 5, a crank 6, a first bevel gear 7, a second bearing seat 8, a hexagonal rod 9, The second bevel gear 10 , the inner helical cylinder 11 , the outer helical cylinder 12 and the collecting device 15 , a first through hole 2 is opened in the middle of the base 1 , a frame body 3 is fixed in the middle of the top of the base 1 , and the upper part of the right side of the frame body 3 is embedded The first bearing seat 4 is installed, the first bearing seat 4 is connected with a rotating shaft 5, the right end of the rotating shaft 5 is fixed with a crank 6, the first bevel gear 7 is installed on the left end of the rotating shaft 5, and the upper part of the inner right side of the frame body 3 is installed There is a second bearing seat 8, the second bearing seat 8 is connected with a hexagonal rod 9, the top of the hexagonal rod 9 i...

Embodiment 2

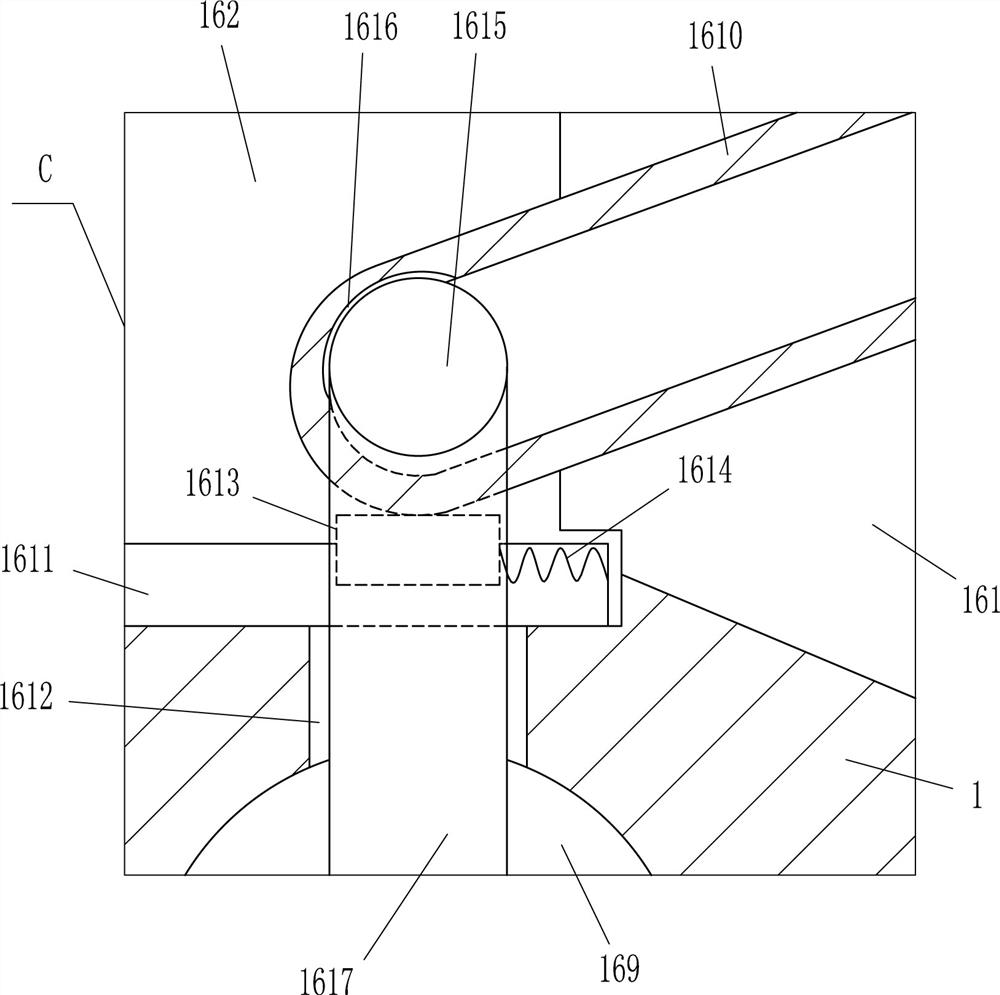

[0026] On the basis of Example 1, see Figure 1-4 , and also includes a fixing device 16 that can fix the device. The fixing device 16 includes a wedge block 163, a horizontal plate 164, a second spring 165, a square frame 166, a pedal 167, a plunger 168, a slotted plate 1610, a slide The rail 1611, the slider 1613, the third spring 1614, the roller 1615 and the universal wheel 1617, the left and right parts of the base 1 are vertically opened with special-shaped grooves 161, the upper right part of the left special-shaped groove 161 and the right special-shaped groove 161 are left. A first groove 162 is opened on the upper part of the side, and a slide rail 1611 is fixed on the bottom of the first groove 162. The slide rail 1611 is slidably provided with a slider 1613, and the slider 1613 slides with the slide rail 1611. A third spring 1614 is connected between the left side of the slider 1613 and the left side of the slide rail 1611, and a third spring 1614 is also connected...

Embodiment 3

[0029] On the basis of Example 1 and Example 2, see figure 1 , also includes a movable rod 17, a U-shaped ferrule 18 and a support rod 19, the lower part of the outer right side of the frame body 3 is hinged with a movable rod 17, and the upper part of the movable rod 17 is hinged with three support rods 19 evenly spaced. A U-shaped ferrule 18 for fixing the movable rod 17 is fixed to the middle of the right side, and the movable rod 17 is located in the U-shaped ferrule 18 .

[0030] When the soil is collected by the device, the operator can pull the movable rod 17 to swing downward, the movable rod 17 swings downward to be separated from the U-shaped ferrule 18, and the movable rod 17 swings downward to drive the support rod 19 to swing downward. The device can be held in an inclined state, and the support rod 19 can be in contact with the ground, and the T-shaped rod 154 can be pushed to make the soil fall into the collecting bucket. When the soil falls into the collecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com