Fixing device and image forming apparatus

A technology of rotating parts and pressure rollers, which is applied in the field of fixing devices and image forming devices, and can solve the problems of decreased cohesion of toner and increased wear of rotating parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

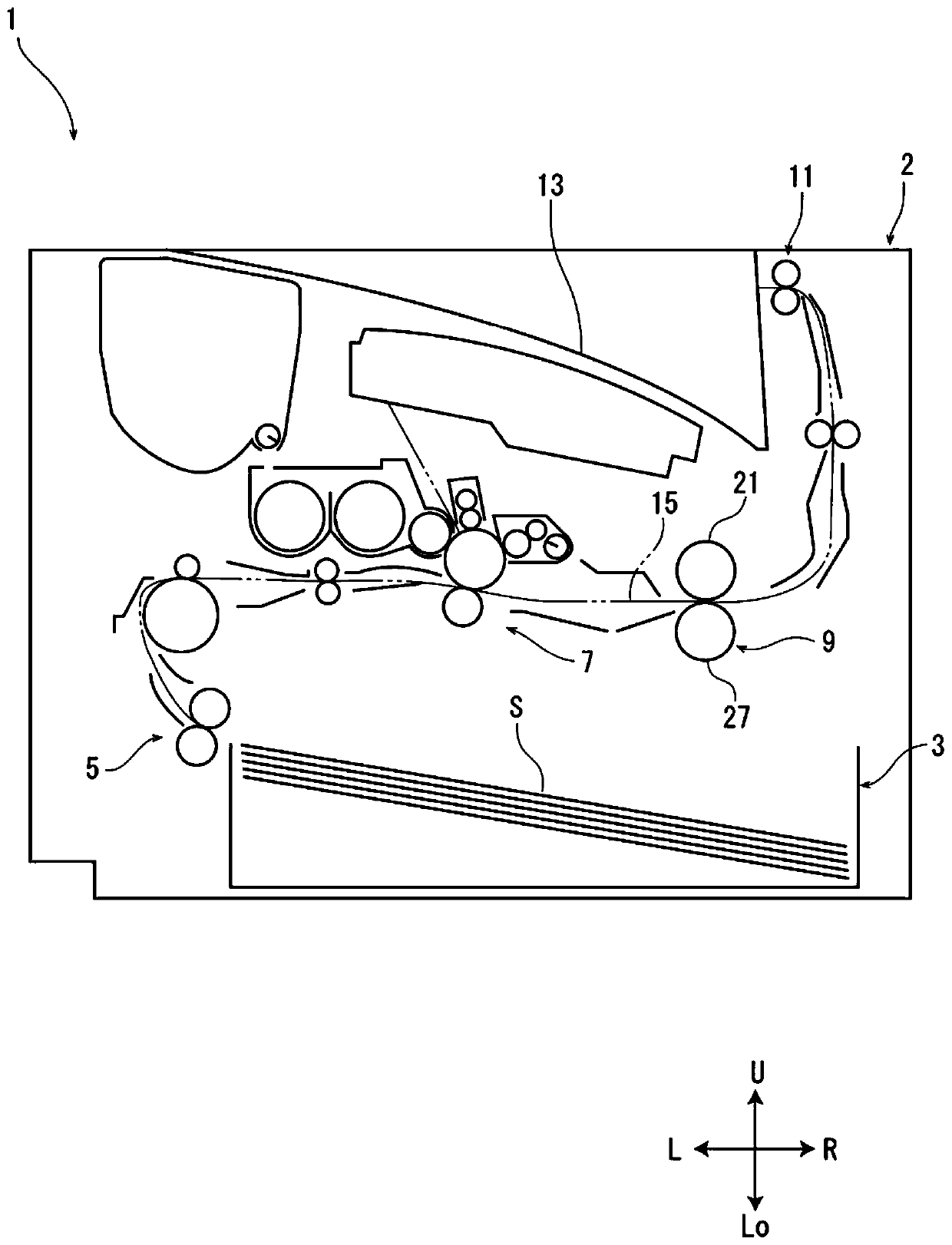

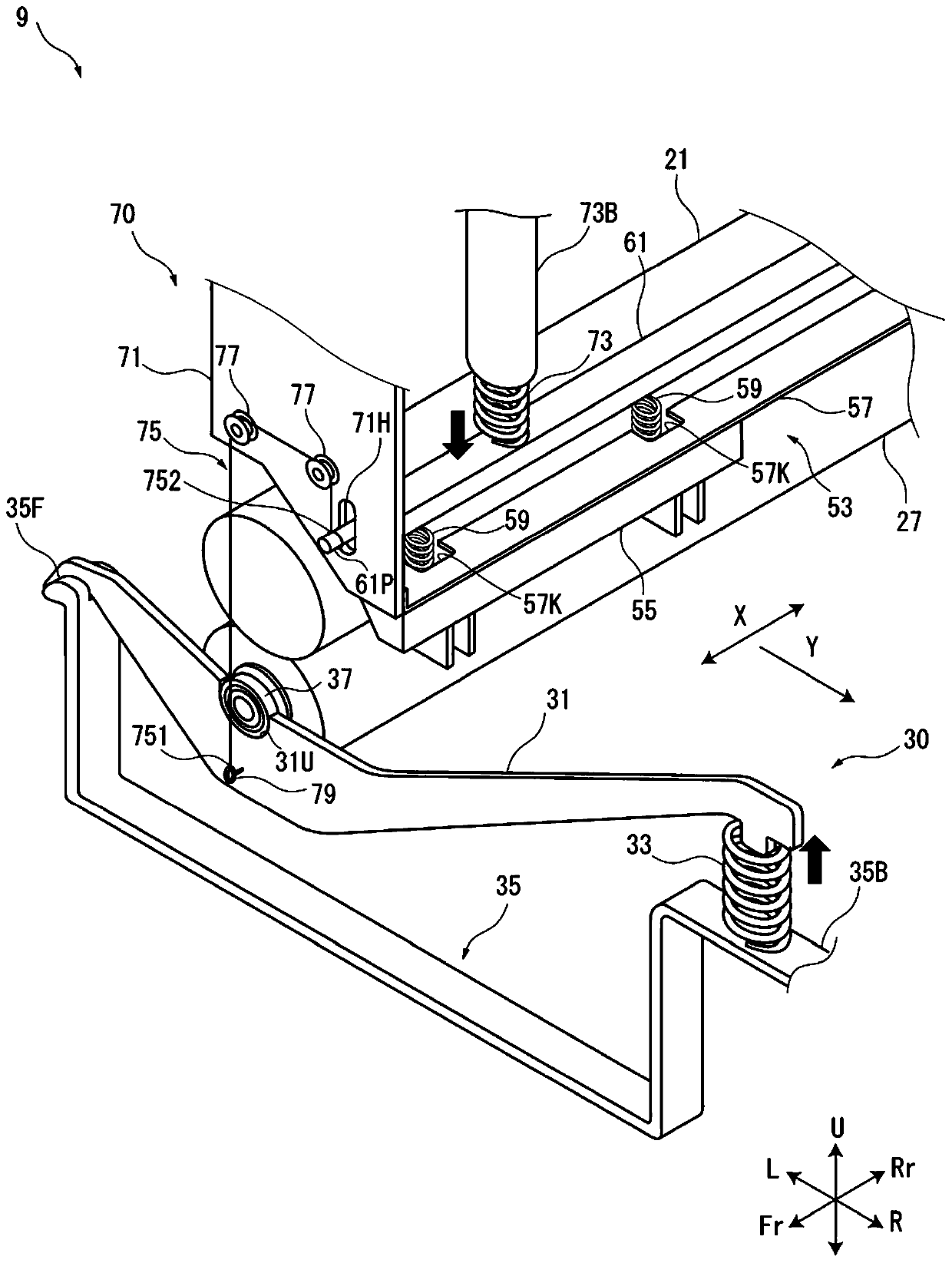

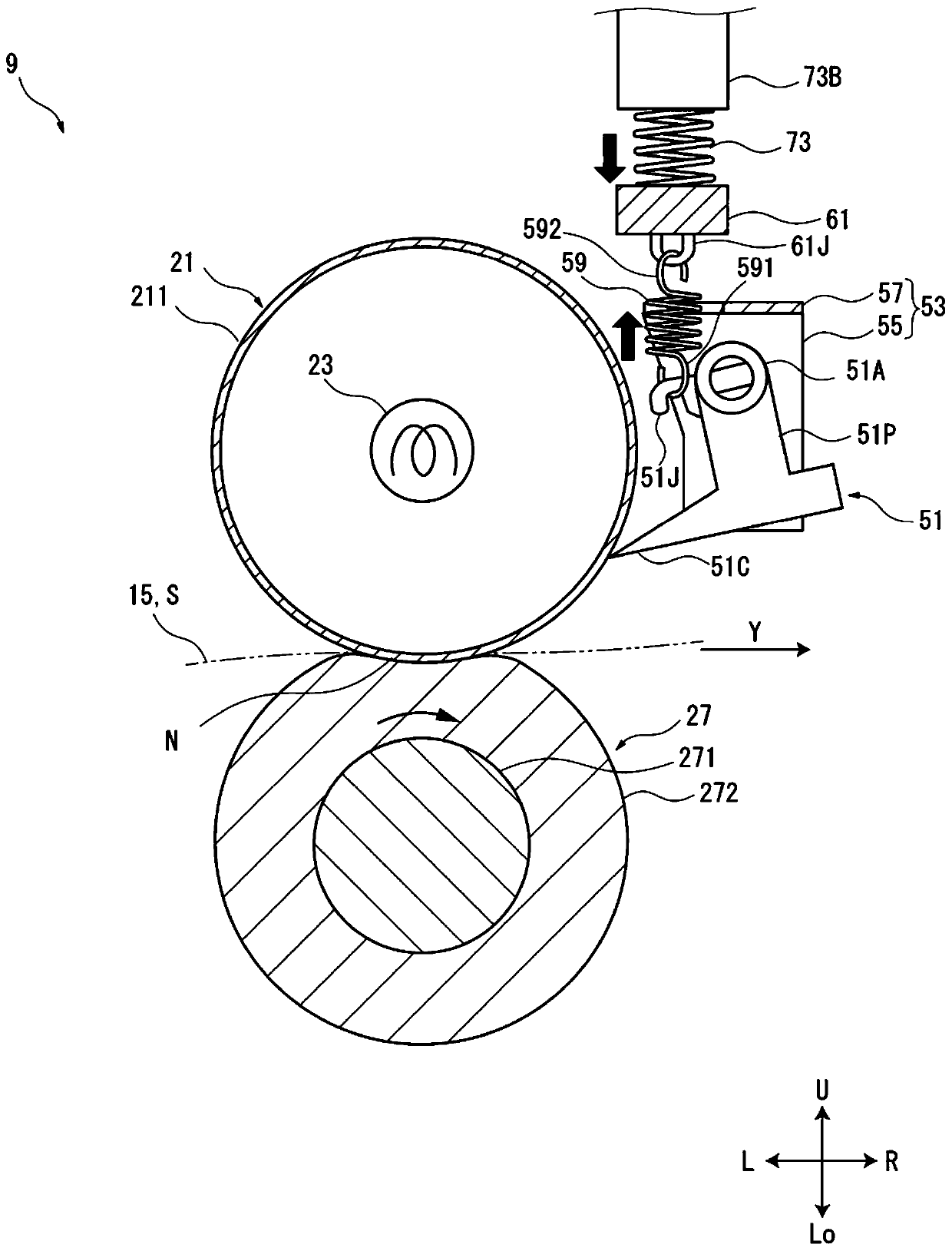

[0021] Hereinafter, an image forming apparatus and a fixing apparatus according to an embodiment of the present invention will be described with reference to the drawings.

[0022] First, refer to figure 1 , the overall configuration of the printer 1 as an image forming apparatus will be described. figure 1 It is a front view schematically showing the internal structure of the printer 1 . Below, will figure 1 The near side of the paper in the figure is the front side (front side) of the printer 1, and the left and right directions are described based on the direction when the printer 1 is viewed from the front. In each figure, U, Lo, L, R, Fr, and Rr represent up, down, left, right, front, and rear, respectively.

[0023] The device main body 2 of the printer 1 includes: a paper feed cassette 3 that stores paper S; a paper feed device 5 that feeds the paper S from the paper feed cassette 3; an image; a fixing device 9 that fixes a toner image on a sheet S; a sheet discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com