Intelligent logistics stowage scheduling method

A scheduling method and intelligent technology, applied in logistics, data processing applications, instruments, etc., can solve the problems of long transportation distance between goods, increased operating costs, dissatisfied vehicle loading, etc., to improve stowage efficiency and reduce the number of reserved warehouse tickets. , The effect of the greatest transportation revenue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

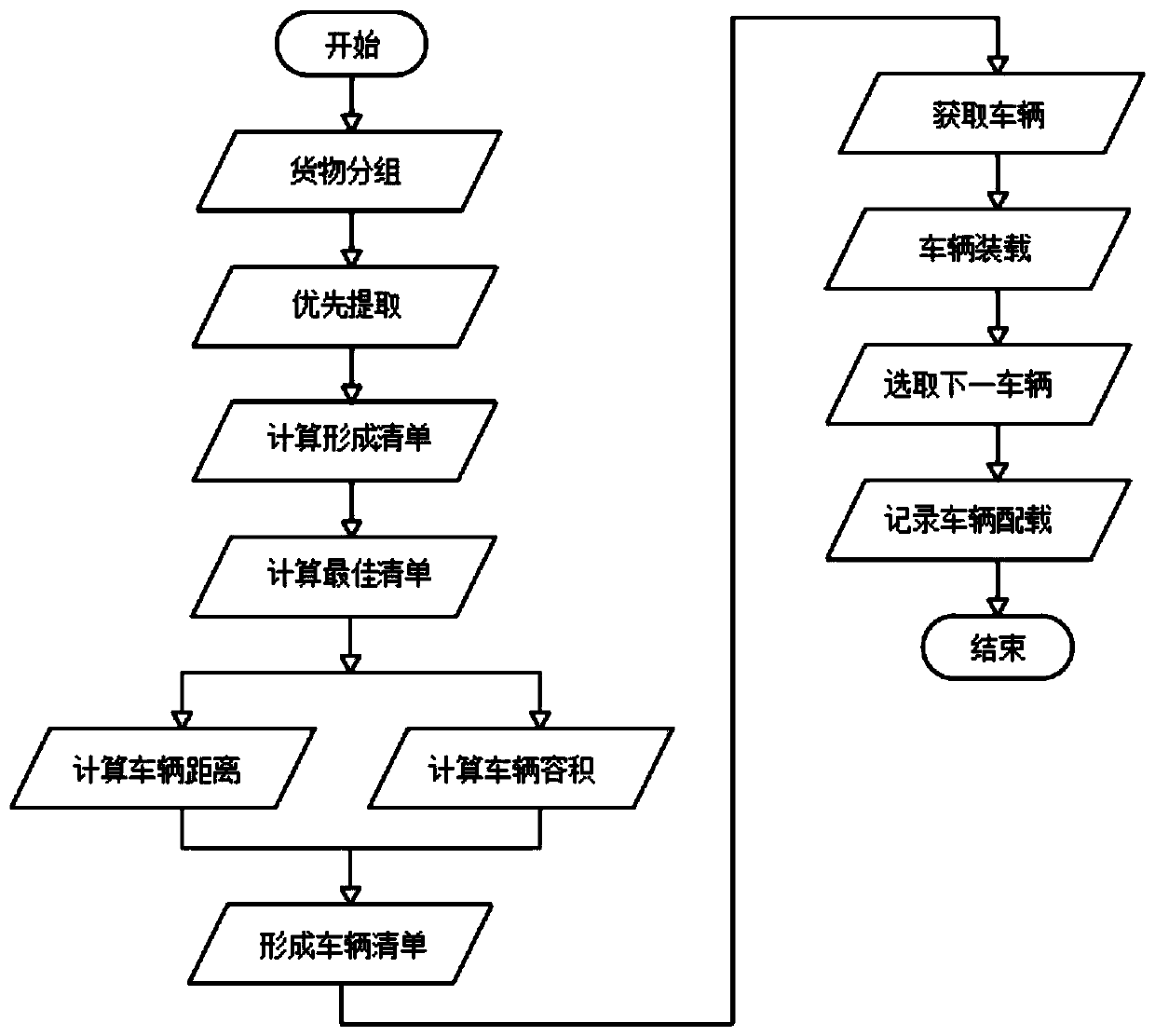

[0033] see figure 1 , a logistics intelligent stowage scheduling method, comprising the following steps:

[0034] S1: Cargo grouping, grouping the goods to be loaded at the current station according to the direction of the goods;

[0035] S2: Pick up first, pick up the goods with the express sign, and pick up the goods in the loading list first;

[0036] S3: Calculate and form a list. For goods in one direction, comprehensively calculate the volume, weight, and value to form a list M to be distributed, arrange and combine the list M to form N cargo loading sets, and input the distribution area information A(A ={1, 2, 3...m}) and all uncombined orders order information D (D={1, 2, 3...n}), order order information includes volume Vd, weight qd and destination da, according to the order The destination coordinates divide the orders into M categories according to the area, sort the M categories of orders in descending order according to the volume, and output M order sequences d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com